Technology improves production in large, semi-intensive shrimp ponds

In Colombia, shrimp culture is typically carried out in semi-intensive systems with relatively large, 5- to 10-hectare grow-out ponds stocked at 18 to 30 postlarvae (PLs) per square meter and reduced water exchange rates of 5 percent per day. Water flow and mass movement in these shrimp ponds are comparatively minimal and simultaneous. The phytoplankton population normally present in the ponds produces significant amounts of dissolved oxygen (DO) during the day. But at night it becomes a net consumer, which can lead to serious DO reduction during early morning hours (3 to 6 a.m.).

These low DO levels are often associated with stressful conditions for stocked shrimp, and occasionally cause massive shrimp mortalities. The use of liquid oxygen injection systems in shrimp ponds has potential to improve this problem.

System tested

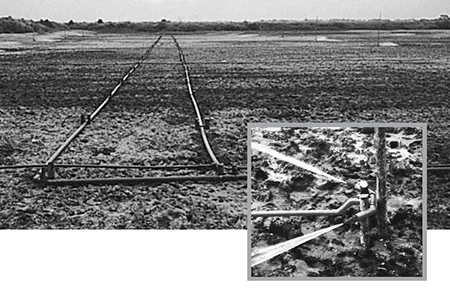

In a collaborative trial sponsored by Agrosoledad S.A., BOC Gases Colombia, and Agribrands Purina Colombia, a method for injecting liquid oxygen into commercial shrimp grow-out ponds was evaluated in Colombia, to assess the possibility of increasing production, net income, and biosecurity. The system injects super-saturated oxygen at greater than 90 ppm directly over the pond bottom through a high-pressure PVC pipe ring, which has multiple nozzles oriented to improve water movement and oxygen homogenization.

The system was installed in two commercial-scale ponds (6.4 and 8.0 ha) at Agrosoledad S.A., near Cartagena, Colombia. The pumping action of the oxygen injection system created a water recirculation rate of 0.2 percent per hour of total pond volume. The system was operated from 10 p.m. to 6 a.m., and calibrated to maintain minimum DO levels over 2.5 ppm to reduce the potential for stressful conditions.

Results

The system was tested during two consecutive production cycles. Production in the experimental ponds increased by almost 37 percent versus traditional ponds, with harvested shrimp of 13-15 g, survival rates over 70 percent, and a feed conversion ratio of 1.6:1.

Pond water exchange compared favorably to non-aerated, non-oxygenated ponds. Experimental ponds used 74 percent of the water exchange typical of traditional ponds, while conventionally aerated ponds used about 94 percent.

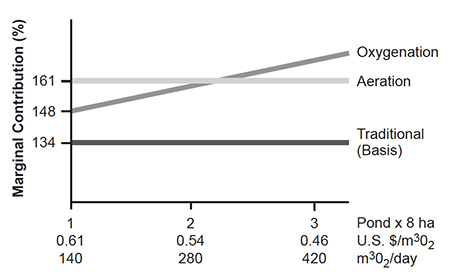

Comparing results with control ponds, the marginal contribution (Fig. 1) – including all oxygenation costs involved in implementing the liquid oxygen injection system – was increased as shown in Table 1.

Negret, Marginal contribution change of traditional, aerated and oxygenated ponds, Table 1

| Pond Treatment | Marginal Contribution Change (%) |

|---|

Pond Treatment | Marginal Contribution Change (%) |

|---|---|

| Traditional (no aeration) | 100% (baseline) |

| Aerated | 47% |

| Liquid Oxygen 8 ha | 34% |

| Liquid Oxygen 16 ha | 48% |

| Liquid Oxygen 24 ha | 61% |

Conclusion

Results of this test showed that liquid oxygen injection systems have potential to maintain minimum DO levels in large, semi-intensive ponds and to improve production and profitability.

(Editor’s Note: This article was originally published in the April 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Enrique Negret, M.Sc.

Proteoliticos Environmental Aquaculture

Bogota, Colombia

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Intelligence

Greenhouse raceways: A consideration for super intensive shrimp production

Greenhouse raceways can be managed with zero to minimal water exchange, thus greatly reducing environmental impacts due to effluent discharge.

Health & Welfare

Fish protein hydrolysates enhance stress resistance of aquaculture species

Fish protein hydrolysates are naturally rich in nutrients that can help support aquatic species’ immune defenses in resisting stressors.

Health & Welfare

Trials advance low-salinity culture of cobia, pompano, other species

Collaborative research in Florida is developing technologies for rearing marine fish in low-cost, low-salinity recirculating systems. Spawning and larval production studies have led to the mass production of juveniles.