Breeding, feeding and biosecurity advances

Financial support in the late 1980s from the European Union was fundamental in providing a solid technological base and the right investment climate from which marine finfish culture has subsequently developed rapidly in Europe. This has primarily been achieved by the development of sophisticated and intensive juvenile production technologies for a number of species. In recent years this technology has been developed and fine tuned to such an extent as to make European intensive larval rearing methods some of the best in the world.

Mediterranean production

In the last 10 years, the production of sea bass (Dicentrarchus labrax) and sea bream (Sparus aurata) in the Mediterranean has increased 10-fold, with over 500 million juveniles produced in 2002. The quality of these juveniles and the efficiency with which they are produced has seen similar progress. The industry today is capable of producing over 120,000 metric tons (MT) of farmed products for the European market, and several new Sparid species are already in commercial production.

New species production

This level of production has been associated with a reduction in market price and profitability, thus forcing companies into increasing production efficiency and economies of scale through acquisitions and mergers, which are a feature of the industry today.

Importantly the development of sensitive reproductive technologies is now being adapted to a range of cold, temperate and warm water finfish species worldwide. In Europe and North America, intensive green water larval rearing techniques are being used to grow a variety of cold water species like cod (Gadus morhua) and halibut (Hippoglossus hippoglossus), and on a pilot scale, wolffish (Anarhichas sp.) and haddock (Melanogrammus sp.). Turbot (Scophthalmus maximus) production is well established in Europe and more recently in China, and several other members of the Sparidae family are being produced in limited numbers in Europe.

In the United States and Asia, similar techniques are being used for warm water finfish species. The Aquaculture Center of the Florida Keys is already producing Cobia (Rachycentron canadum) and mutton snapper juveniles (Lutjanus analis). Asian producers are concentrating their research efforts on even more technically challenging species, such as groupers and tunas.

A number of recent advances have played a vital role in the development of customized and specific zootechnical protocols.

Broodstock and egg supplies

The requirement for a year-round egg supply demanded the establishment of more sophisticated broodstock holding facilities, with both light and temperature control. In order to achieve spawning, modern facilities replicate ambient environmental conditions, which may be then displaced by several months to achieve a year round supply of eggs. Broodstock tanks typically vary in size from 15 to 50 tons and are provided with heated, cooled and ambient water supplies. Some facilities use individual recirculation units where water supplies and water quality are limiting parameters.

Broodstock nutrition

The understanding of broodstock nutrition has played a significant role in the improvement of fecundity and egg quality. Highly unsaturated fatty acids (HUFA) and vitamin enrichment of broodstock diets have been shown to relate directly with levels of these compounds in the eggs of a variety of species. Further, the practice of feeding trash fish is less common today as farmers are more aware of the health and disease implications of these actions.

Larval nutrition

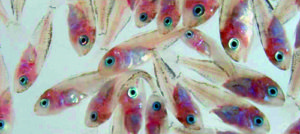

All the species mentioned above (with the exception of halibut) have small pelagic eggs varying in diameter from 0.8 to 1.3 mm. On hatching, their very small larvae require the presence of microscopic plankton species as feed organisms, and these planktonic species must meet the nutrition requirements for the particular fish species being cultured. In most hatcheries, this includes unicellular marine algae, commonly Nannochloropsis sp., and Isochrysis sp., the rotifer (Brachionus plicatilis), and the brine shrimp (artemia salina).

Today, unicellular algae play a lesser role in the direct nutrition of these fish larvae, but are still an important factor in the larval rearing environment. These algae contribute to rotifer nutrition and the maintenance of water quality parameters, and also affect light dispersion that can beneficially affect the feeding response of the larvae.

Algae production

Photo-bioreactors are replacing traditional sack and tank algal culture systems, because they offer an automated, labor-saving and cost-effective method of production, and resulting cell concentrations can reach up to 10 times those achieved by traditional methods. Concentrated algal pastes are also becoming commercially available, and should they prove effective in the larval rearing environment, they could soon negate the necessity for marine hatcheries to produce their own live algae.

Rotifer production

Rotifer production methodologies have also improved. Today, culture densities of 2,000 rotifers per milliliter are routine, and high-density cultures of 5,000 rotifers per milliliter are achievable using a variety of commercial products. Automated systems are being commercialized for the first time, reducing the space required as well as the operational and investment costs.

Artemia

Artemia decapsulation, hatching and enrichment techniques have reached a high level of efficiency due to the variable availability and high cost of its cysts. A number of efficient, commercial enrichment diets are available for rotifers and artemia. Through their bioencapsulation, the ratios of HUFA (EPA, DHA, ARA) can be manipulated in live food organisms, and total levels of HUFA may exceed 60 miligrams per gram dry weight if required. Specialized products combining both enrichment and hygiene control for artemia are capable of altering the microbiological characteristics of the hatching and enrichment environments. These powerful bio-manipulative tools provide today’s aquafarmer with customized nutritional packages that help reduce disease risks associated with the live food chain.

Inert feeds

Until very recently this live food chain was solely responsible for the nutrition of these fish larvae until they were nearly 30 days old. However, current improvements in inert feed manufacturing techniques – combined with a better understanding of larval enzyme development – have resulted in the development of artemia replacement diets and co-feeding regimes from as early as day 17 into the larval rearing cycle. This means that with well-understood species such as sea bass and sea bream, artemia consumption has been reduced to 30 percent of original levels, greatly reducing the cost of production and length of the larval cycle.

Water quality

The larval rearing process requires high quality water, and sea water supplies may be recirculated, filtered, UV-sterilized or treated with ozone. In certain areas, saline borehole water supplies have proven to be an excellent source of water that in general is relatively sterile and requires little filtration and other treatments. The temperature of this water is often constant, thus reducing and simplifying heating and cooling requirements.

In larval rearing, careful attention must be paid to the control of water temperature, gas saturation of inlet water, light levels, hydrodynamic conditions within the tank, live food densities, and general tank hygiene. Surface skimmers remove debris and oil films from the water surface, ensuring early swim bladder inflation. Zootechnical and husbandry factors such as the ones described above play an important part in increasing larval rearing survivals, reducing juvenile deformity and ensuring cost effective production.

Biosecurity

As in other intensive production industries, hygiene management and prophylactic disease control are essential in the modern marine fish hatchery. Biosecurity of discrete areas within the hatchery complex are features of modern design, and management procedures include shut down and sterilization periods as standard. Intensive production systems require that regular grading is undertaken to prevent cannibalism, stress and disease outbreaks. The use of immunostimulants and vaccines contribute to a healthy biosecure status within the farm environment.

Finally, careful production planning and the commitment of management to the strict enforcement of the principles discussed above are essential precursors to the successful operation of modern hatcheries for marine fin fish juvenile production.

(Editor’s Note: This article was originally published in the February 2003 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

John Sweetman

Ecomarine Ltd.

Samoli, Livadi, 28200

Lixouri, Cephalonia, Greece[114,103,46,108,111,104,64,110,105,114,97,109,111,99,101]

-

Richard Prickett

Marine Farm Technology Ltd.

Appleton, Oxon, U.K.

Tagged With

Related Posts

Health & Welfare

Bacterial testing improves biosecurity at marine hatchery

Microbial surveys of hatchery operations at Oceanic Institute found a strong correlation between hatchery success and cultivable bacteria levels in the water supplied to the larval-rearing systems.

Intelligence

Global finfish production review: Gradual growth

Recent surveys indicate that global finfish production has doubled over the last decade, but most of this growth happened in the first half of this period. Production is still growing but at slower pace than in recent years, and annual growth rates must increase to at least 7.2 percent to maintain the double-in-a-decade objective.

Health & Welfare

Nutrition impacts pigmentation, eye migration In Atlantic halibut

Atlantic halibut juveniles fed artemia in the larval stage often exhibit insufficient pigmentation and lack proper eye migration.

Intelligence

A review of European marine finfish hatcheries

As European aquaculture continues to diversify in the marine fish sector, technology advances and methodology in marine finfish hatcheries are proving vital.