Trials seek best balance of artemia, formulated diets

Much has been said and written about brine shrimp’s key role in the development and sustainability of shrimp and marine fish fry production. Artemia cysts have been at times both glorified and cursed by various stakeholders in the aquaculture industry.

Several institutes and companies have researched the viability of a complete substitution of artemia by a formulated diet. Although some claim to have found the perfect alternative, the fact remains that shrimp seed producers agree that live artemia remain indispensable for an optimal production process. Many confirm that one can grow shrimp larvae without artemia, but admit that doing so will inevitably compromise the survival, growth rate or overall condition and health of the animals.

Artemia issues

Artemia is a natural product obtained by harvesting natural bodies of water. The ability of suppliers’ cyst harvests and inventories to meet market demand therefore relies on the unpredictability of Mother Nature. Every year, this impacts availability, quality and price. Also, the artemia resource is limited.

Artemia harvest data from the last 25 years indicates that during years with favorable conditions, the natural annual production peaked around 3,000 metric tons. All of those cysts were consumed every year by the aquaculture industry. On the other hand, according to the forecasts of the United Nations Food and Agriculture Organization, World Bank and other entities, the yield from seafood production is expected to double during the next 15 years. It is obvious that such growth can only be realized when more fry can be produced with less artemia.

Other reasons to search for artemia alternatives include the biosecurity concerns inherent to any live and fresh feeds, and the well-documented fact that due to their very specific habitats, some strains of artemia have an incomplete nutrient profile to sustain optimal development of marine organisms. In addition, the obligatory cyst hatching and nauplii preparation required for artemia production make them less user-friendly than an off-the-shelf product.

Artemia benefits

Live artemia offer important benefits when compared to formulated diets. One is the ease with which artemia are digested by their prey. Once the nauplii are captured, autolysis sets in and substantially assists shrimp larvae’s own still incomplete digestive systems. Another important advantage is the fact they are alive. Artemia nauplii swim around in the water column. They don’t sink and eventually pollute the water like leftover formulated diets tend to do. This is especially important in one-phase culture systems that are still the preferred rearing technique in Asia.

Other benefits include the fact that artemia nauplii are the perfect biocarriers for enrichment with nutrients and health components that improve the overall yield of larviculture of fish and shrimp. Additionally, persistent “live factor” characteristics such as attractability and palatability warrant the exceptional dietary status of artemia.

Replacement Trials

INVE Technologies N.V., the research and development company of INVE Aquaculture, has carried out trials to evaluate the effects of artemia reduction on the hatchery culture performance of Litopenaeus vannamei shrimp by partially and fully replacing the artemia with commercial larval feeds, most notably a series of improved formulations that has been recently introduced as the Frippak Fresh Gold range.

Pilot scale

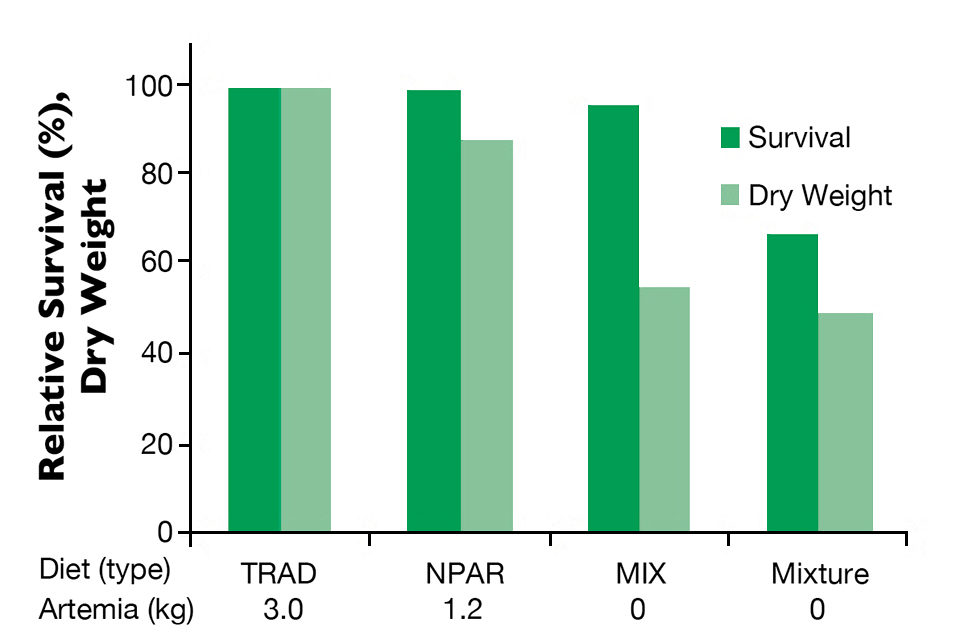

A series of pilot-scale experiments was executed at INVE Aquaculture’s test center in Thailand. Control cultures in all tests consumed approximately 3 kg artemia cysts/million P.L.10. Their performance was compared to cultures in which only about half of this amount was fed and to cultures where artemia content was reduced to zero. In the control runs, the artemia were supplemented with traditional microencapsulated larval shrimp diets formulated with fresh and natural ingredients (TRAD). The tanks with reduced artemia input were supplemented with the new partial artemia replacement (NPAR). Zero-artemia treatments were fed 100 percent formulated diets, either NPAR or a mixture of commercially available industry-standard formulated diets (MIX).

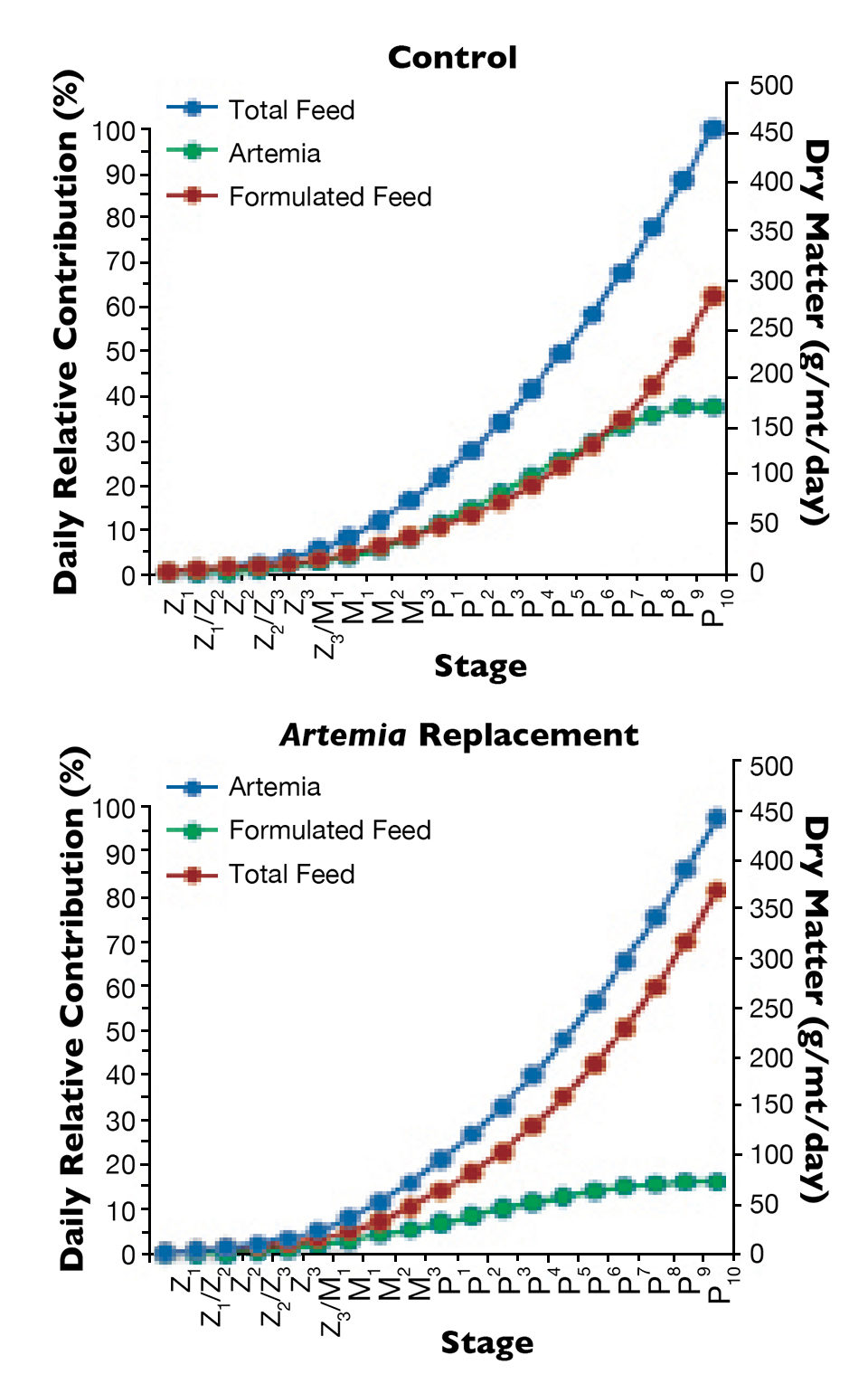

The progression and ratios of the live artemia and artificial diets are pictured in Figure 1. The animals showed similar larval development and survival in the control and treatments with partial artemia replacement. Lengths and postlarvae counts were not significantly different (P > 0.05). In setups with zero artemia, significantly slower growth rates were recorded. Except for the tanks that received the new artemia replacement, survival was also significantly reduced (Fig. 2).

Commercial scale

Following the pilot-scale trials, further validation was sought in industrial systems. Commercial-scale trials were carried out in four production units, two in Latin America and two in Southeast Asia.

In the Americas, the culture systems employed a two-phase protocol with transfer at P.L.4/5. Larvae were cultured in either flat-bottom or parabolic rectangular tanks, and postlarvae were transferred to flat-bottom raceways.

In Asia, the feeding regimes used a cocktail of partial artemia replacements and other diets, including flakes. The culture systems used one-phase protocols.

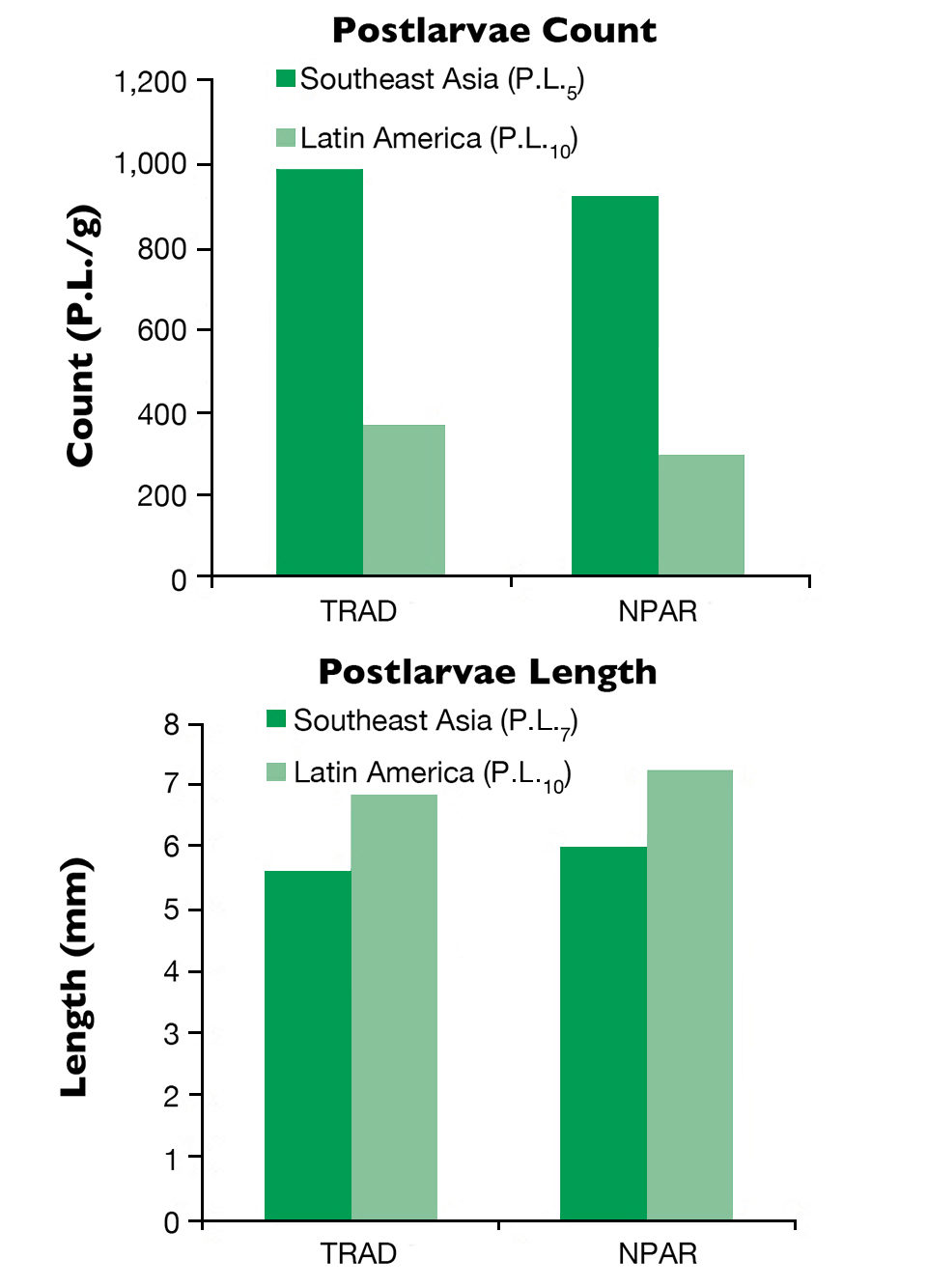

In the American systems, the artemia replacement ratio was 60 percent, with 40 percent replacement in the Asian trials. The results obtained in all four systems showed no adverse impacts of the reduced artemia on yield (survival, development and growth) and quality of the postlarvae at harvest. On the contrary, faster development and growth were registered (Fig. 3). Survival was similar to that in the control feeding regimes for all treatments.

Aside from the similar to better culture yields, a key advantage of partial artemia replacement is its beneficial impacts on larval production cost. Cost analysis of the commercial production runs revealed important savings when applying the replacement protocol (Table 1).

Southeast Asia: Production Of 1 Million P.L.8

| Feed Component Compound Diets | TRAD Requirement (g) | NPAR Requirement (g) | TRAD Cost (U.S. $) | NPAR Cost (U.S. $) |

|---|---|---|---|---|

| NPAR | NPAR | 688 | 9.30 | 57.30 |

| TRAD | TRAD | 237 | 0 | 7.40 |

| Other diets | 3,082 | 1,655 | 110.20 | 52.90 |

| Artemia | 1,799 | 1,056 | 134.50 | 79.40 |

| Total cost | 254.00 | 197.00 | ||

| Benefit (%) | 22.40 |

Latin America: Production Of 1 Million P.L.12

| Feed Component Compound Diets | TRAD Requirement (g) | NPAR Requirement (g) | TRAD Cost (U.S. $) | NPAR Cost (U.S. $) |

|---|---|---|---|---|

| NPAR | 75 | 1,487 | 5.90 | 111.40 |

| TRAD | 0 | 1,956 | 0 | 48.60 |

| Other diets | 4,917 | 1,244 | 138.50 | 15.60 |

| Artemia | 3,000 | 1,200 | 212.60 | 78.00 |

| Total Cost | 357.00 | 253.60 | ||

| Benefit (%) | 29.00 |

(Editor’s Note: This article was originally published in the March/April 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Eddy Naessens

INVE Aquaculture

Hoogveld 93

9200 Dendermonde, Belgium[109,111,99,46,101,114,117,116,108,117,99,97,117,113,97,101,118,110,105,64,115,110,101,115,115,101,97,110,46,101]

-

Roeland Wouters, Ph.D.

INVE Aquaculture

Hoogveld 93

9200 Dendermonde, Belgium -

Rattayaporn Phuthongphan

INVE Aquaculture

Hoogveld 93

9200 Dendermonde, Belgium -

Erik Van Ballaer

INVE Aquaculture

Hoogveld 93

9200 Dendermonde, Belgium

Tagged With

Related Posts

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.

Health & Welfare

Acclimating shrimp postlarvae before pond stocking

Shrimp postlarvae acclimation before stocking into the various growout systems (ponds, raceways, tanks) is a critical – and often overlooked, sometimes taken for granted – step in the shrimp culture process. Various water quality parameters should be changed slowly so that the young shrimp have the time to gradually adapt to the new conditions.