Trial evaluates bead filtration, foam fractionation and pressurized sand filtration

Concerns regarding influent disease epizootics and the environmental impacts of aquaculture effluents have led the shrimp-farming industry to research methods of increasing biosecurity and reducing environmental impacts through limited water exchange. With these objectives, the authors conducted a 74-day nursery study at the Texas Agricultural Experiment Station Shrimp Mariculture Research Facility in Corpus Christi, Texas, USA, in the spring of 2003.

Raceway study

Three 45-cubic-meter, HDPE-lined, greenhouse-enclosed raceways designed to refine the biosecure management of intensive nurseries were operated under limited water discharge. The performance of Pacific white shrimp (Litopenaeus vannamei) was evaluated using three water treatment systems: bead filtration, foam fractionation, and pressurized sand filtration. Selected water quality indicators were monitored to assay the systems and their effects on shrimp growth and survival.

All culture tanks were equipped with a longitudinal center partition positioned over a bottom water distribution manifold. Water mixing and circulation was generated by 18 airlift pumps made of 5.1-mm PVC pipe positioned on both sides of the partition and water pumped through the bottom manifold and its associated spray nozzles. Aeration was provided via six 1-m-long air diffusers and a venturi injector operated with air or oxygen.

The raceways were filled with filtered seawater adjusted to 30 ppt salinity using municipal freshwater. Following chlorination and dechlorination of the residual chlorine after 24 hours, the water was inoculated with the marine diatom Chaetoceros muelleri at 50,000 per milliliter. Raceways were stocked with 5-day-old postlarvae (PL).

Stocking, feeding

Although stocking density was intended to be similar, an error during the stocking process resulted in densities of 3,800; 6,500; and 5,000 PL per cubic meter for raceways operated with the bead filter, pressurized sand filter and foam fractionator, respectively. Newly hatched artemia nauplii were fed during the first 10 days after stocking.

Dry feed rations with 45 to 50 percent crude protein were then targeted at 18 percent per day of total estimated biomass down to 7 percent per day toward harvest. Rations were further adjusted based on feed consumption and growth.

Environmental parameters, harvest

Temperature, dissolved oxygen, pH, and salinity were monitored at least twice daily. Settleable solids were monitored daily beginning on day 49. Ammonia, nitrite, nitrate, reactive phosphorus, total suspended solids, volatile suspended solids, five-day carbonaceous biochemical oxygen demand and chemical oxygen demand were monitored weekly in each tank. Random shrimp samples were sent for disease diagnosis every two weeks.

The bead filter and foam fractionator were operated continuously for 46 days. The pressurized sand filter was operated for only 33 days with an average daily use of 25 minutes. At harvest, shrimp were netted in baskets weighed after water drained for 20 seconds. Another 5 percent of the recorded yield was subtracted to account for excess water weight. Survival rates were based on total biomass and shrimp average weights.

Samocha, Changes in water quality over 74 days, Table 1

| Day | Water Quality Indicators (mg/l) cBOD5 | Water Quality Indicators (mg/l) COD | Water Quality Indicators (mg/l) NH3-N | Water Quality Indicators (mg/l) NO2 | Water Quality Indicators (mg/l) NO3 | Water Quality Indicators (mg/l) RP | Water Quality Indicators (mg/l) TSS | Water Quality Indicators (mg/l) VSS |

|---|---|---|---|---|---|---|---|---|

| 1 | 9.2 | 580 | 2.09 | 0.21 | 3.52 | 1.48 | 20 | 10 |

| 7 | 5.2 | 413 | 1.52 | 0.05 | 4.54 | 1.30 | 90 | 10 |

| 15 | 4.5 | 626 | 3.78 | 0.60 | 2.22 | 7.16 | 110 | 35 |

| 22 | 6.2 | 2,651 | 2.48 | 3.55 | 11.37 | 2.32 | 40 | 25 |

| 28 | 6.2 | 1,681 | 2.22 | 5.68 | 21.56 | 3.00 | 45 | 30 |

| 35 | 9.2 | 3,883 | 2.40 | 8.79 | 20.64 | 3.18 | 110 | 60 |

| 42 | 18.5 | 2,323 | 2.59 | 13.69 | 50.38 | 3.59 | 120 | 80 |

| 49 | 58.8 | 4.88 | 19.07 | 74.42 | 5.39 | 220 | 110 | |

| 56 | NA | NA | 0.42 | 0.78 | 35.26 | 9.38 | 400 | 200 |

| 58 | 54.9 | NA | 4.99 | 4.93 | 41.42 | 11.78 | 600 | 500 |

| 63 | 17.6 | NA | 8.38 | 0.87 | 51.18 | 15.54 | 300 | 250 |

| 70 | 36.8 | NA | 15.02 | 0.10 | 55.82 | 20.63 | 400 | 150 |

| 74 | 73.6 | NA | 22.64 | 0.78 | 55.39 | 25.57 | 700 | 200 |

cBOD5 = Five-day carbonaceous biochemical oxygen demand

COD = Chemical oxygen demand

NH3-N = Ammonia nitrogen

NO2 = Nitrite

NO3 = Nitrate

RP = Reactive phosphorus

TSS = Total suspended solids

VSS = Volatile suspended solids

Results

Overall yields ranged 2.42 to 5.26 kilograms per cubic meter for the study (Table 2). Survival rates ranged 96.3 to 100 percent, while FCRs varied 1.09 to 1.70. The raceway operated with the pressurized sand filter at the highest stocking density produced the best survival, average weight, and yield with the lowest FCR value and water exchange (less than 0.5 percent per day) among the three raceways.

Samocha, Performance summary of the intensive nursery study, Table 2

| Treatment | PL/m3 | Initial Weight (mg) | Days | Final Weight (g) | Yield (kg/m/m3) | Survival (%) | New Water (% total volume/day) | FCR |

|---|---|---|---|---|---|---|---|---|

| BF | 3,780 | 0.6 | 74 | 0.65 | 2.42 | 96.3 | 1.35 | 1.70 |

| PSF | 6,540 | 0.6 | 74 | 0.85 | 5.26 | 100.1 | 0.47 | 1.09 |

| FF | 5,010 | 0.6 | 74 | 0.69 | 3.18 | 97.8 | 2.06 | 1.50 |

BF = Bead filter PSF = Pressurized sand filter FF = Foam fractionator

Although high ammonia and nitrite levels were found in the culture water, all harvested shrimp were in apparent excellent health, with no visual signs of bacterial or viral infection, no external fouling or damage to cuticles and no broken appendages.

Pressurized sand filter

Table 1 summarizes the changes in water quality indicators in the raceway operated with the pressurized sand filter. The results suggested that accumulation of particulate matter under well-mixed and oxygenated water conditions stimulated the development of beneficial microorganisms that can help with the nitrification process.

Furthermore, the low FCR value obtained in this system suggested the shrimp actively fed on bacterial flocs and other particulate matter developed in the system. Four days before the harvest of this raceway, a constant 40 liters per minute supply of oxygen was needed to support the high oxygen demand.

Foam fractionator

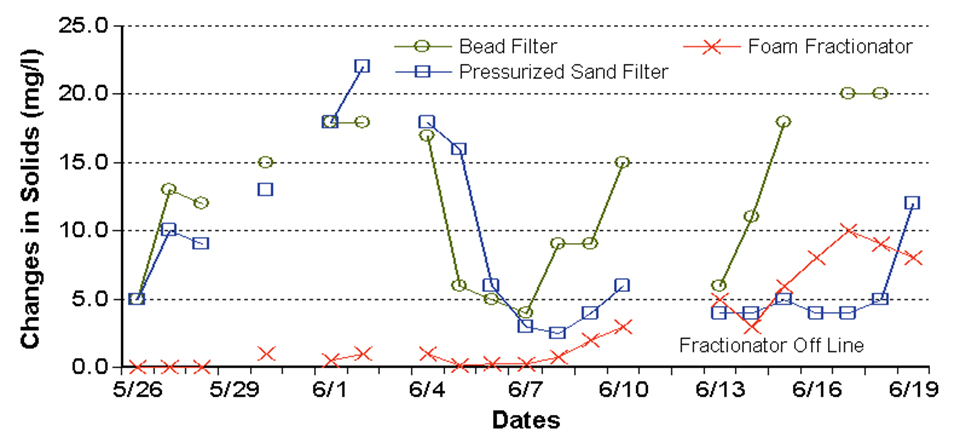

The raceway with the foam fractionator had a persistent green algal bloom of up to 5 x 106 cells per milliliter throughout the study. The efficient removal of the particulate matter by the foam fractionator (Fig. 1) may have resulted in this heavy blooming. Occasional water exchanges were needed to alleviate shrimp stress created by the blooms.

To avoid further deterioration of the shrimp health, the foam fractionator was taken off line about a week before the harvest. Interestingly, the raceway operated with the bead filter also required occasional water exchanges to alleviate signs of shrimp stress. Inadequate filtration may have been to blame for the inferior performance of the shrimp in this raceway.

(Editor’s Note: This article was originally published in the August 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

M. Handy

Texas Agricultural Experiment Station

Shrimp Mariculture Research Facility

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

T.M. Samocha, Ph.D.

Texas Agricultural Experiment Station

Shrimp Mariculture Research Facility

4301 Waldron Road

Corpus Christi, Texas 78418 USA[117,100,101,46,99,99,117,109,97,116,64,97,104,99,111,109,97,115]

-

S. Patnaik

Texas Agricultural Experiment Station

Shrimp Mariculture Research Facility

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

R.L. Gandy

Texas Agricultural Experiment Station

Shrimp Mariculture Research Facility

4301 Waldron Road

Corpus Christi, Texas 78418 USA -

D.A. McKee

Texas A & M University

Corpus Christi, Texas, USA

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Health & Welfare

‘Boutique’ RAS for spotted sea trout

A boutique design project validated a land-based, recirculating production system capable of producing 50 metric tons of spotted sea trout per year.

Innovation & Investment

Flow rate estimation for RAS

The water quality in recirculating aquaculture systems is generally a function of the tank size, biomass, feed inputs and waste treatment efficiency. Adequate biofiltration can control the build-up of ammonia-nitrogen and nitrate-nitrogen in the systems.

Health & Welfare

Microbial flocs for aquaculture

Microbial flocs consist of a variety of bacteria, fungi, microalgae and other organisms suspended with detritus in culture water.