Comparative economics and environmental performance vs. conventional grow-out systems

Biofloc technology (BFT) promises to revolutionize tilapia and shrimp aquaculture industries globally. In fact, leading scientists believe that harnessing the flow of microbes to fish represents the next revolution in food production (see part 1 and part 2 of this article). Despite indicative growth and feed cost savings demonstrated in experimental tilapia BFT systems in China, Indonesia and Vietnam few reports exist describing the relative economic and environmental performance advantages of BFT from the commercial sector.

Insightful experience gained at Chambo Fisheries in Malawi, where a large-scale BFT fish farm was developed then monitored over a period of three years (December 2013 to December 2016), helps fill many of these knowledge gaps.

SustAqua Fish Farms (SAFF) is well positioned to report on the economics of tilapia culture based upon two decades of data capture across five major tilapia farming systems from semi-intensive earth ponds to RAS, aquaponics and BFT systems including Chambo Fisheries, purportedly the largest BFT farm raising tilapias in the world, and the largest tank farming operation raising finfish in Africa.

Comparative economics of biofloc technology vs. conventional tilapia grow-out systems in Malawi

Four tilapia grow-out systems, which excludes a hatchery, were selected based upon current or perceived future popularity on the African continent among 16 grow-out systems defined by SAFF for comparative economics. All four grow-out farms were designed to output 800 tons per annum of Shiranus tilapia (Oreochromis shiranus) located near (on-shore) or on Lake Malawi (near-shore) at an elevation of 480 meters above sea-level;

1) Large-scale lake cage culture

2) SAFF BFT-farm

3) Greenwater pond farm

4) SAFF One-Tank RAS farm

Capital investment costs based upon the application of an optimized design philosophy for each of the four tilapia grow-out systems are defined in Table 1 (below) and described below with the aid of images.

Based upon capital investment, scalability and simplicity of management it is likely that lake-cage culture and greenwater pond farming will become the dominant grow-out production systems for tilapia within the sub-Sahara Africa Region although these are not necessarily the most resource use efficient, sustainable and least cost production technologies.

Kourie, BFT Pt. 3, Table 1

| Definition of major capital cost items | Large-scale lake cage farm | SAFF tilapia BFT farm | Greenwater pond farm | SAFF one-tank RAS farm |

|---|---|---|---|---|

| Land | 20,000 | 50,000 | 333,333 | 36,000 |

| Feed store, feed plant, office, stores | 50,000 | 70,000 | 65,000 | 50,000 |

| Tanks, greenhouses, filtration, plumbing, electric | 0 | 1,120,000 | 0 | 1,200,000 |

| Earthworks, roads, run-off drainage | 6,000 | 40,000 | 30,000 | 12,000 |

| Ponds, pumps, water supply, pre-filtration, water storage | 0 | 250,000 | 1,500,000 | 300,000 |

| Cages, nets, mooring, anchor blocks | 1,808,000 | 0 | 20,000 | 0 |

| Service boats, crane, canoes | 23,000 | 0 | 2,000 | 0 |

| Fish pump | 14,000 | 0 | 18,000 | 0 |

| Wooden pier | 10,000 | 0 | 0 | 0 |

| Farm equipment | 25,000 | 580,000 | 150,000 | 650,000 |

Kourie, BFT Pt. 3, Table 2

| Economic parameter inputs | Large-scale lake cage farm | SAFF-BFT farm | Greenwater pond farm | SAFF one-tank RAS farm |

|---|---|---|---|---|

| Investment, US$/kg annual production | 2.51 | 2.73 | 2.86 | 2.89 |

| Total capital investment, US$ | 2,011,000 | 2,180,000 | 2,288,333 | 2,313,000 |

| Food conversion ratio | 1.6 | 1 | 1 | 1.3 |

| Feed protein content, % | 32 | 20.2 | 30.1 | 32 |

| Feed cost (US$/ tonne) -on-site manufacture in SAFF-BFT | 800 | 550 | 755 | 800 |

| Cost of fingerlings of 10g average weight, US$/ fish (own production) | 0.035 | 0.035 | 0.035 | 0.035 |

| Power cost, US$/kWh | 0.085 | 0.085 | 0.085 | 0.085 |

| Selling price of fish, US$/kg (gate) | 3 | 3 | 3 | 3 |

| Unit cost of production inputs | Large-scale lake cage farm | SAFF-BFT farm | Greenwater pond farm | SAFF one-tank RAS farm |

| Unit feed input cost/kg live weight | 1.28 | 0.55 | 0.755 | 1.04 |

Large scale lake cage culture

System and hardware components consist of HDPE cages, mooring and anchor blocks, workboats, crane, brail nets, feed barge and a pier (Fig. 1). Capital costs vary from $1.8 to 2.2 million considering growth rates and cycle duration to raise 800 tons of 250-gram O. shiranus per annum. A median investment cost of $2.011 million was applied to the study.

Large scale cage culture requires bought-in extruded feeds costing $800 per ton (given collective industry scale economies, or produced on site – additional investment) for a 32 percent protein grower feed based upon achievable feed conversion ratios (FCRs) of 1.6:1

The major challenges faced by large-scale cage culture are theft and vandalism where stock losses of 2.5 percent were applied into the economic model and high FCR of 1.6:1 achieved in practice.

SAFF- BFT farm

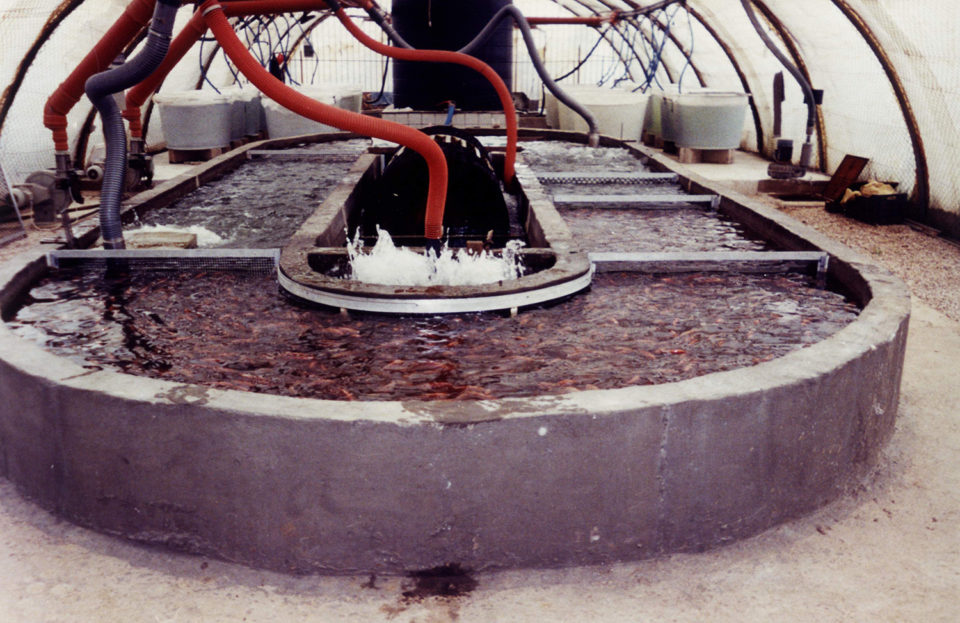

System and hardware components (Fig. 2) include tanks, greenhouses, lamella separator, airlift pond water pumps, floor diffusers, blowers and plumbing, paddlewheel aerators, electrical switchgear, cabling and control panels, back-up power etc. Capital costs vary from $1.96 million to $2.37 million, while a median value of $2.18 million was applied into the study.

The BFT farm makes use of local feedstuff raw materials (see Part 2) and a built-in low cost moist feed milling plant producing pressed pellets on-site for a 20.2 percent protein (approx. C/N of 15.5:1) at a cost of $550 ton. No animal protein in feeds for fish > 5 grams where FCR’s of 1:1 on 20.2 percent protein have been achievable in practice. Power input of 1.7 kWh/kg of fish production is achievable (see Part 1). Stock losses attributed to theft were applied at 0.5 percent of farm production.

BFT represents a biosecure technology initiated with specific pathogen free (SPF) broodstock following quarantining after which production is free of the use of chemicals and therapeutic agents, and also environmentally-friendly, producing zero-effluent discharge.

Kourie, BFT Pt. 3, Table 3

| Relative production cost advantage of the SAFF-BFT | Large-scale lake cage farm | SAFF tilapia BFT farm | Greenwater pond farm | SAFF one-tank RAS farm |

|---|---|---|---|---|

| Farm gate production cost, US$/kg of production (live weight) | 2.01 | 1.25 | 1.39 | 1.69 |

| Difference, US$/kg | 0.76 | 0.00 | 0.14 | 0.44 |

| Difference, % | 61.2 | 0 | 11.3 | 35.4 |

| Ranking | 4 | 1 | 2 | 3 |

Greenwater pond farm

Greenwater pond farming involves the use of earth ponds managed semi-intensively (Fig. 3), using conventional manure and fertilizers until fish reach 100 to 150g before feeding formulated feeds based upon detailed studies conducted in Thailand.

Anticipated yields raising 250-gram O. shiranus would require around 224 days per cycle to output on average 7 tons/Ha/cycle requiring around 100 Ha of land and 77 Ha of ponds to produce 800 tons per annum (Fig. 3). Capital costs include purchasing land at $3,333 per hectare and almost $19,500 per hectare of pond construction including pumps, water supply, pre-filtration, water storage, drainage structures etc. A total capital investment of $2.9 million in round figures is anticipated.

A bought-in 30 percent protein feed costing $755 per ton and yielding a final anticipated FCR of 1.1:1 would match results achieved in Thai greenwater pond farms. Stock losses due to theft of 2.5 percent were considered.

SAFF-One-Tank RAS

System and hardware components (Figs. 4 and 5) include tanks, greenhouses, lamella separator, moving bed biofilters, foam fractionators, airlift pond water pumps, floor diffusers, blowers and plumbing, aerators, electrical switchgear, cabling and control panels, back-up power, etc. Capital costs vary from $2.2 to 2.4 million. A median value of $2.33 million was applied into the economic model.

The farm would have a built-in low cost moist feed milling plant producing pressed pellets and would make use of local feedstuff raw materials. No animal protein in feeds for fish > 40 grams where a 32 percent protein feed would yield a practicable FCR of 1.27 at a cost of $800 per ton raising 250-gram fish.

A power input cost of 1.3 kWh/kg of fish production has been achieved using a SAFF-One-Tank RAS. Stock losses attributed to theft were applied at 0.5 percent of farm production.

RAS represents a biosecure technology initiated with SPF broodstock following quarantining after which production is free of the use of chemicals and therapeutic agents, and also environment friendly and producing zero-effluent discharge.

Economic modelling results of BFT vs. conventional tilapia grow-out technologies

Favorably low FCRs of 1:1 on 20.2 percent protein (=C/N ratio 15.5:1) feeds at Chambo Fisheries under biofloc conditions represents significant feed (and fertilizer) cost savings which comprises 54 to 64 percent of the make-up of the live weight farm gate production cost in lake cage culture, greenwater pond farming and RAS farming. Comparatively feed costs only represents 44 percent of the farm gate production cost in the SAFF-BFT farm.

The SAFF-BFT farm then is the most efficient form of industrial tilapia production when compared to large-scale lake cage culture, greenwater pond farming and RAS farming. The farm gate production cost advantage of the BFT Shiranus tilapia farm over the large-scale lake cage culture operation, greenwater pond farm and SAFF-One-Tank RAS farm was 61.2 percent, 11.3 percent and 35.4 percent respectively.

Table 4 provides an account of product yield and energy and protein retention in the edible parts of Atlantic salmon, pigs, lamb, beef steers and broiler chickens compared to the four tilapia farming systems selected for economic comparison.

Notice in Table 4 that broiler chicken farming and pig farming are more protein efficient than typical tilapia cage culture implying that the advantages of fish culture are somehow lost due to inefficiencies inherent under the lake cage culture model where FCRs in practice are seldom below 1.6:1.

The SAFF-BFT farm then is the most efficient form of industrial tilapia production, and equally more efficient than the production of Atlantic salmon, pigs, beef steers, lamb and broiler chickens, outperforming large-scale lake cage culture, greenwater pond farming and RAS farming. The main drivers of large-scale commercial tilapia culture using the best choice feral tilapia species (O. shiranus) in Malawi are feed costs and theft since capital costs among the four grow-out operations are quite similar.

Kourie, BFT Pt. 3, Table 4

| Measurement parameter | Atlantic salmon | Biofloc raised tilapia (realized) (f) | RAS raised tilapia (g) | Cage culture tilapia (typical) (h) | Greenwater Tilapia Ponds (j) | Pigs | Broiler chickens | Beef (i) | Lamb |

|---|---|---|---|---|---|---|---|---|---|

| Harvest yield (%) (a) | 86 | 86.8 | 86.8 | 86.8 | 86.6 | 72.5 | 65.6 | 62.5 | 46.9 |

| Edible yield (%) (b) | 68.3 | 46.3 | 46.3 | 46.3 | 46.3 | 52.1 | 46.1 | 40.0 | 38.2 |

| FCR (c) | 1.15 | 1.00 | 1.27 | 1.60 | 1.1 + fertilizer N | 2.63 | 1.79 | 12.7 | 6.3 |

| Net Energy retention (%) (d) | 23.0 | 20.9 | 15.9 | 12.5 | 19.3 | 14.0 | 10.0 | n/a | 5.0 |

| Net Protein retention (%) (e) | 31.0 | 36.6 | 18.3 | 14.0 | 10.8 | 18.0 | 21.0 | 5.0 | 5.0 |

a Harvest yield is yield of gutted and blend animal

b Edible yield is ratio of total body weight that is normally eaten, muscle, body adipose tissue and liver, lung, and heart for pig. Skin is excluded from all animals except in tilapia where skin has been counted. Harvest and edible yields for tilapia based upon the work of El-Zaeem et al. 2012 determined for 125 to 185g tilapia.

c FCR = (kg feed fed)/ (kg body weight gain)

d Net Energy retention = (energy in edible parts)/ (gross energy fed) for all animals except tilapia taken at whole carcass energy content from Lupatsch (2012)

e Net Protein retention = (kg protein in edible parts)/ (kg protein fed) for all animals except tilapia taken at whole carcass protein content from Lupatsch (2012)

f FCR data based upon results achieved at Chambo Fisheries feeding 20.2% protein feed (C/N ratio = 15.5:1) feeding 127g to 147g Oreochromis shiranus

g FCR data from Chowdury eta al. (2013) feeding a 32% protein feed, GE of 16.7MJ/kg, DE of 14.3 MJ/Kg raising fish up to 220g

h FCR data based upon achievements in large scale cage culture raising 127/147g Nile tilapia (O. niloticus) on 32% protein extruded feeds

i FCR, edible meat yield, energy and protein retention as percentages of edible meat yield in beef taken from Smil (2002)

j Calculated from Diana et al. (1994). Supplemental Feeding of Tilapia in Fertilized Ponds. JOURNAL OF THE WORLD AQUACULTURE SOCIETY Vol. 25, No. 4 December 1994.

Comparative sustainability indicators of BFT vs. conventional tilapia farming systems and other animal husbandry systems

The battle to conquer malnutrition in Africa cannot be won at the expense of the environment. To counter the deleterious environmental effects of aquaculture growth, expected to more than double by 2050 from 2012 production levels, the World Resources Institute (WRI, 2014) has issued a plea for aquaculture development to abide by a set of directives in their report entitled, “Improving productivity and environmental performance of aquaculture.”

Increased investment in technological innovation and transfer and the promotion of low-impact production systems are among the major themes covered in the WRI report:

“Recirculating aquaculture systems, biofloc technology, and integrated systems perform well across most indicators of productivity and environmental performance. Conduct additional research to understand and manage resource tradeoffs, bring down production costs, and develop additional low-impact systems that ease resource constraints.”

How well does BFT compare to conventional tilapia grow-out technologies in terms of resource use and sustainability indicators? The four tilapia grow-out technologies detailed under the economics section are now compared in a head-to-head fashion in terms of the following environmental sustainability and resource use indicators:

-

- Food conversion (kg feed/kg edible weight).

- Whole carcass protein efficiency (%).

- Nitrogen (N) emissions (kg/ton protein produced).

- Phosphorus (P) emissions (kg/ton protein produced).

- Land use expressed as tons of edible product per hectare of land surface area (tons edible product/Ha).

- Consumptive freshwater use expressed as cubic meters (m3) of water use per ton of animal on a whole carcass basis (m3/ton).

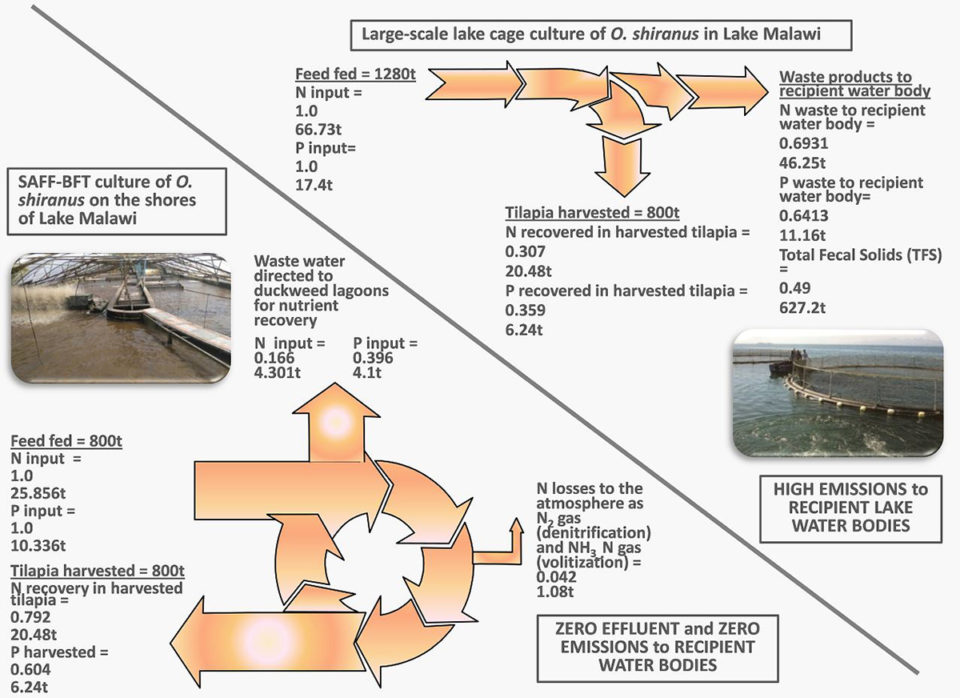

Fig. 7 provides an interesting account of the fate of nitrogen (N), phosphorus (P) and total faecal solid wastes (TFS) comparing the BFT farm to the large-scale lake cage culture farm. It is quite apparent that large-scale lake cage culture is the least environmentally sustainable of the four tilapia grow-out farms.

Large-scale greenwater pond farming requires significant volumes of clean water and space requiring careful site selection often in low-lying valleys on the African sub-continent often also some distance away from urban markets increasing the costs of logistics. Due to the location of cages in public waters and the vast expanse of the greenwater pond farm, both of these grow-out technologies are more prone to theft than the BFT and RAS farms. In fact, RAS and BFT can be likened to leap-frog technologies not dissimilar to mobile networks which have greatly superseded the roll-out of ground-line communication systems in recent years on the African sub-continent which are difficult to protect from high-value copper theft.

Perspectives

The future of commercial tilapia culture in Africa offers a very sanguine outlook given forecasted fish supply shortfalls expected to hit seven million tons by 2030 according the Food and Agriculture Organization (FAO). Transport and fish delivery logistics also require to be factored into site selection. It was calculated that a commercial pond farm in rural Mozambique would experience a delivery cost of $0.43/kg to bring fish to the distant urban masses.

Many inland high-altitude cities (>1000 meters above sea level) offer a sub-optimal climate for year-round tilapia farming, and many coastal African cities face acute shortages of freshwater. Then the smaller footprint and more resource use efficient (particularly water use) and low impact RAS and BFT technologies (which can be placed within a greenhouse enclosure) seem to offer the most hope where production can be located on the doorstep to many large African cities (achieving gate sales) simultaneously reducing the cost of logistics to bring the crop into urban markets.

Author

-

Ramon M. Kourie

Chief Technical Officer

SAFF - SustAqua Fish Farms (Pty) Ltd

14 Branch Lane, Blairgowrie, 2625

Johannesburg, South Africa

http://sustaquafishfarms.co.za

Tagged With

Related Posts

Responsibility

Optimizing tilapia biofloc technology systems, part 1

Chambo Fisheries, the world’s largest tilapia biofloc tank farm and the largest tank farm in Africa, has a multi-cohort, sequential, continuous production schedule.

Responsibility

Optimizing tilapia biofloc technology systems, part 2

Chambo Fisheries, one of the world’s largest tilapia biofloc tank farms and the largest in Africa, has developed its own, on-farm production of specialized feeds and procedures to optimize feed applications and feeding rates.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Intelligence

Biofloc technology production promising in temperate zones

A study was conducted to assess the feasibility to grow Channel catfish (Ictalurus punctatus) in an outdoor biofloc system during winter in a temperate zone. High biomasses of market-size channel catfish were successfully maintained through the winter with high survival and in good condition in both treatments.