Low D.O. linked to poor growth and feed consumption rates

At present, there is limited knowledge on the hydrographical conditions at salmon cage sites along the Norwegian coast. While water temperature, a key factor for the control of feed supply, is currently monitored at all farms, monitoring of dissolved oxygen (D.O.) is not commonly practiced at Norwegian cage farms.

Dissolved-oxygen levels

D.O. is affected by water exchange, the effects of algal production, upwelling of deep water low in oxygen and other factors.

At D.O. levels of inflowing water above 90 percent of saturation, a current velocity of only a few centimeters per second will ensure sufficient D.O. at 6 milligrams per liter or greater levels in intensively stocked (25 kilograms per cubic meter) cages during the summer along the Norwegian coast, where water temperatures are 13 to 18 degrees-C. Some salmon farmers have observed short-duration, reduced D.O. levels as low as 3 to 4 milligrams per liter in salmon cages during the warmer months of July to September. These levels are close to lethal concentrations for salmonids.

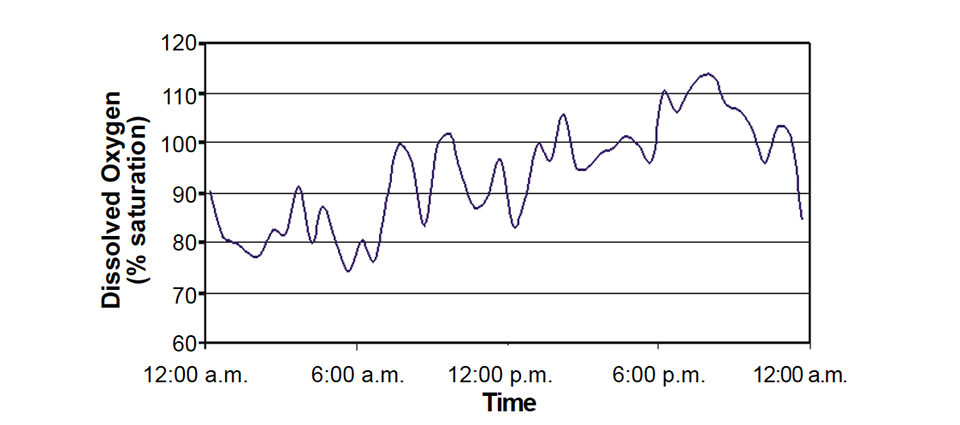

Mainly due to algae photosynthesis, a diurnal D.O. fluctuation is usually observed at cage sites in fjords and along the coast during the summer and early autumn, with a peak in the afternoon and minimum at night before dawn (Fig. 1). Consequently, the risk of critical D.O. deficits in the salmon cages is highest at night and in the morning at first feeding.

Critical conditions

In the summer and fall of 2002, long-lasting warm weather caused critical conditions for cage-based salmon in Norway. Water temperatures of about 20 degrees-C and D.O. concentrations temporarily below 50 percent of saturation in late August to early September resulted in loss of appetite and stagnant growth.

At EWOS’ research stations outside Stavanger, as many as 2,500 4-kg salmon died per cage, and more than 20 percent of the smolts stocked in the spring were lost. Similar losses were reported at numerous cage farms in southern Norway during this period. This critical period cut the potential production in Norway by more than 100,000 metric tons (MT) in 2002 to 2003.

Critical D.O. levels in sea water fish cages during this time of the year have also been reported from several other regions with salmon cages, including British Columbia and Tasmania, and for yellowtail farms in southern Japan. Low D.O. concentrations during peak growth periods can limit the potential production of oxygen-sensitive fish species in marine cage farms.

Oxygen injection study

A study at EWOS Innovation in Dirdal, Norway, showed the poor tolerance of Atlantic salmon for low D.O. concentrations. The growth rate and feed consumption of adult fish were significantly reduced when D.O. levels dropped below 65 to 80 percent of saturation, even at the rather low temperatures of 8 to 10 degrees-C.

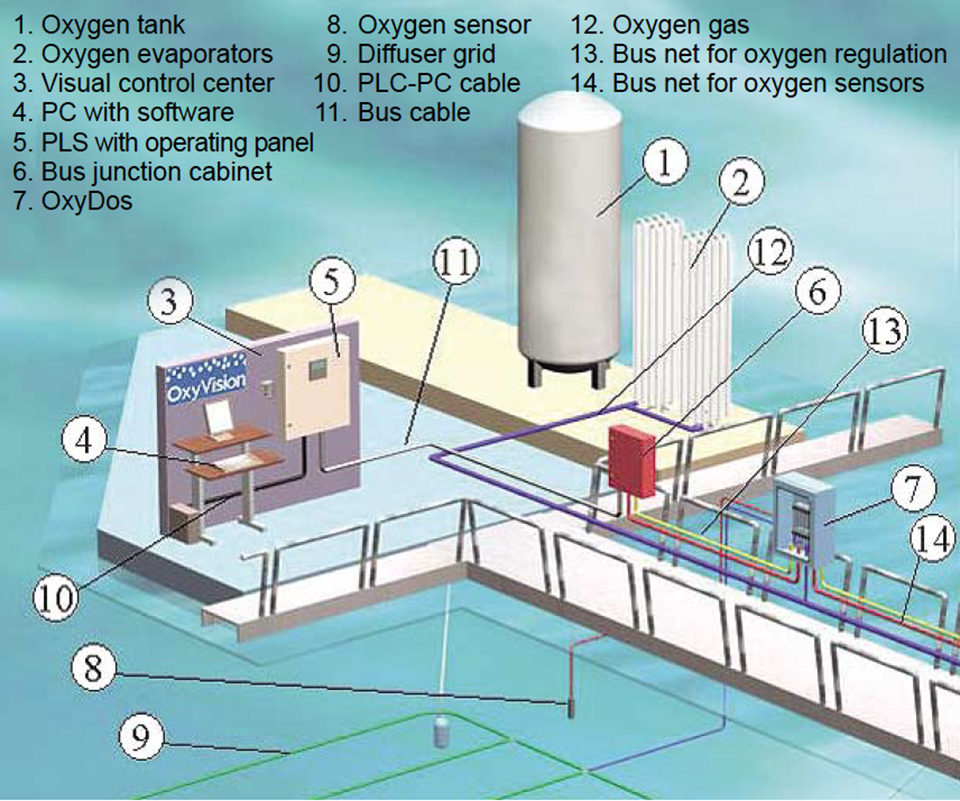

A system for oxygen injection in fish cages introduced a couple of years ago can supply pure oxygen from a diffuser grid submerged in the cages. The dosage rate is controlled by dosage valves, special oxygen probes, and a PLC system that can control the oxygen level between set points.

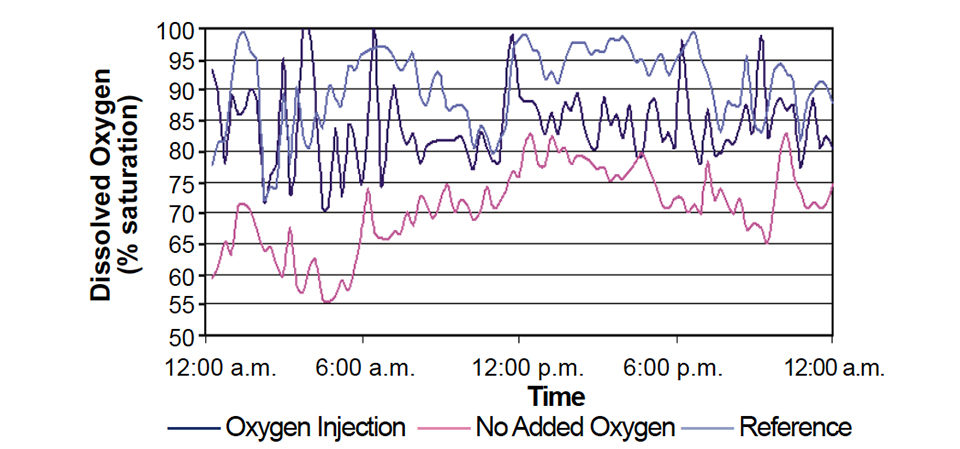

The oxygen injection equipment has demonstrated promising results at several cage sites. In tests at EWOS Innovation’s Oltesvik site, D.O. concentrations were compared between a cage with added oxygen, a cage without oxygen addition, and a sampling point outside the cages (Fig. 2).

Throughout the day, the fish consumed 1 to 3 mg oxygen per liter, while the oxygen addition efficiently increased the concentration in the oxygenated cage, mainly above the 85 percent of saturation set point of the oxygen dosage.

The sea water temperature in July to October 2003 was relatively moderate, with levels as high as 18 to 20 degrees-C lasting only a couple of weeks. Injection of oxygen during the last two months until harvesting still increased the growth rate by about 10 percent and produced an additional biomass of about 6 MT in a cage stocked with 20,000 salmon, representing a significantly higher net profit.

(Editor’s Note: This article was originally published in the August 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Asbjorn Bergheim, Ph.D.

Senior Researcher

R.F.-Rogaland Research

4068 Stavanger, Norway -

Martin Gausen

OxSeaVision as

Surnadal, Norway -

Anders Næss

OxSeaVision as

Surnadal, Norway -

Viv Crampton

EWOS Innovation

Dirdal, Norway -

Per Holland

EWOS Innovation

Dirdal, Norway

Tagged With

Related Posts

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Responsibility

Airlifts combine pumping, water treatment in recirculation systems

Using the buoyancy of the entrained air bubbles to lift the water, airlifts are more energy-efficient and provide more aeration, carbon dioxide removal and foam fractionation for dissolved solids removal than centrifugal pump systems.

Responsibility

Oxygen injection systems provide emergency aeration, D.O. management

In intensive ponds and raceways, oxygen injection can manage oxygen demand and can quickly increase dissolved-oxygen levels to minimize risk of catastrophic failure.

Health & Welfare

Ozone treats water, disinfects aquaculture systems

Ozone is a strong oxidizing agent that effectively removes colors, odors and turbidity from water, and kills bacteria, viruses and other microorganisms.