More powerful than chlorine, usage is recognized as safe

There is an increasing need for new sanitizers to control infection and diseases, as well as reduce the accumulation of undesirable chemicals in water and air. Many chemicals have been employed as antimicrobial compounds – including heavy metal salts, halogenated compounds, gases, oxidizers, and alcohols – but ozone has characteristics that make it highly desirable for disinfection and sanitizing.

Ozone results from the rearrangement of atoms when oxygen molecules are subjected to a high-voltage electric discharge. The product is a bluish gas with a pungent odor and strong oxidizing properties that effectively inactivate bacteria, fungi, and viruses.

Strong and safe

Ozone is a strong and generally safe disinfectant and sanitizer. It is more powerful than chlorine, the most commonly used disinfectant, for inactivation of large numbers of microorganisms. It has been used in water treatment for nine decades and is approved in the United States as “generally recognized as safe” (GRAS) for the treatment of bottled water.

Ozone has been applied in the European food industry for almost a century. Recently, an expert panel in the United States affirmed ozone as a GRAS substance for broad food applications. Numerous recent investigations of food disinfection, including the use of gaseous ozone for increasing storage life and ozone dissolved in water for sanitizing the surfaces of vegetables, fruits and other agricultural products, support the position that ozone is a powerful disinfectant.

Since it does not remain in water for a long period, ozone can be considered a process aid rather than a food additive, with no safety concerns about consumption of residual ozone in food products. Any byproducts that ozone produces during treatment of foodstuffs are similar to normal oxidation products, do not contain chlorine, and are less likely to have deleterious health effects than the byproducts of chlorine treatment.

Ozone treatment requires no heat and hence saves energy. Also, the gas must be produced on site and therefore saves transportation and storage costs.

Limitations

Ozone no doubt provides effective treatment for a range of processing applications. But it has limitations. Ozone is relatively stable in air, but in aqueous solution, its stability depends almost entirely on the amount of ozone-demanding material in the solution. The cleaner the water, the longer the ozone half-life. In clean water used to wash food, ozone lasts several hours, while dirty water can shorten ozone’s half-life to seconds.

As the pH of ozone-containing solutions increases, the rate of ozone decomposition also increases. With rising pH, the efficiency of ozone decreases for certain rotaviruses, until at a pH of about 10, the ozone decomposes instantaneously. Furthermore, unwanted byproducts from ozone action on organic compounds can shorten the shelf-life, change the organoleptic quality, or jeopardize the safety of final products.

Effects on food

In the food-processing environment, ozone can undesirable quality deterioration. It can cause surface oxidation and therefore may promote oxidative spoilage. Ozone has caused discoloration and undesirable odors in treated muscle foods such as fish cake due to lipid oxidation.

Ozone can also cause color changes in treated foods. Alterations in the sensory attributes of seafood products depend on the chemical composition of the food, ozone dose, and treatment condition.

Ozone generation, health issues

Ozone can be produced by ultraviolet bulbs, which generate relatively low levels in the range of 0.1 percent by weight or about 1,200 ppm. To achieve the higher concentrations of ozone needed for commercial applications, however, the corona discharge method is employed. The method is capable of achieving ozone concentrations of approximately 18 percent by weight or about 216,000 ppm.

Since ozone can be generated in high concentrations, incorrectly designed process systems could endanger workers by releasing excessive ozone. Process failure or product damage could also result from inadequate generation or distribution of ozone.

The use of ozone in areas that lack adequate ventilation can pose a significant hazard to workers. Even low concentrations of ozone can cause irritation of the nose, throat, and eyes. A one-hour exposure to ozone concentrations of 2, 4, 15 and 95 ppm induces symptomatic, irritant, toxic and irreversibly lethal effects, respectively.

Worker safety

Worker safety is of prime importance for the practical application of ozone in seafood processing. In addition to respirators, systems for ozone detection and destruction are essential.

Ultraviolet analyzers equipped with measuring cells adapted to a range of 0.01 to 100 ppm by volume be installed in ozonation rooms at intervals to cover ozone gas distribution pipes, contractor access galleries and ozone destruction points. The analyzers must trigger an alarm as soon as the ozone content in the ambient air exceeds 0.01 ppm.

Furthermore, protective canister-type respirators must be kept available. United States regulations state that individuals must not be exposed to ozone concentrations higher than 0.1 ppm during an eight-hour work day.

Effects on bacteria, yeasts, parasites

Ozone inactivates numerous bacteria, including both Gram-negative and Gram-positive cells, vegetative cells, and spore formers (Table 1). It is not feasible to compare the sensitivity of bacteria to ozone using results from different sources because the effectiveness of ozone varies appreciably with minor changes in experimental variables.

Flick, Inactivation of gram-negative bacteria, Table 1

| Bacterium | Ozone Concentration (ppm) | Treatment Time (minutes) | Inactivation (log10) |

|---|

Bacterium | Ozone Concentration (ppm) | Treatment Time (minutes) | Inactivation (log10) |

|---|---|---|---|

| Escherichia coli | 0.065a | 0.5 | 3.5 |

| E. coli | 0.004-0.8b | 0.5-2.0 | 0.5-6.5 |

| E. coli | 0.23-0.26a | 1.67 | 4.0 |

| E. coli 0157:H7 | 0.3-1.0a | < 0.5 | 1.3-3.8 |

| Salmonella typhimurium | 0.23-0.26a | 1.67 | 4.3 |

| Bacillus megaterium | 0.19 | 5 | > 2.0 |

| B. cereus | 0.12 | 5 | > 2.0 |

| Listeria monocytogenes | 0.2-1.8 | 0.5 | 0.7-7 |

| L. monocytogenes | 0.1a | 10 | 60-70b |

| Staphylococcus aureus | 0.3-1.97 | 10 | 4-6 |

| S. aureus | 0.25 | > 2.0 | |

| B. cereus (spores) | 2.29 mg/l | 5 | > 2.0 |

Since many pathogenic and spoilage microorganisms occur in relatively low concentrations in food plants that employ good manufacturing practices, a 2- or 3-log reduction in a microbial population may provide significant product safety to consumers and also extend product shelf life. A 1-log reduction means bacterial populations are reduced by 90 percent, a 2-log reduction means 99 percent fewer bacteria, a three-log reduction means 99.9 percent fewer, etc.

The inactivation effects of ozone on yeasts and parasites is contained in Table 2. Both Cryptosporidium parvum and Giardia lamblia have been reported in Atlantic coast oysters. However, no illness has been reported from ingestion of the parasites, even though many oysters are consumed raw.

Flick, Inactivation of protozoa by ozone, Table 2

| Protozoan | Ozone Concentration (ppm) | Treatment Time (minutes) | Inactivation (log10) |

|---|

Protozoan | Ozone Concentration (ppm) | Treatment Time (minutes) | Inactivation (log10) |

|---|---|---|---|

| Cryptosporidium parvum | 1 | 5 | > 1.0 |

| Giardia lamblia | 0.7 | 1.1 | 2.0 |

| Candida parapsilosis | 0.23-0.26 | 1.67 | 2.7 |

| C. tropicalis | 0.02-1.0 | 0.30-0.08 | 2.0 |

Applications in seafood processing

As reported in varied research, ozone treatments improve the sensory quality of fish by reducing surface contamination and decreasing the formation of trimethylamine. References for the study results described below are available from the author.

The viable bacterial count of fresh jack mackerel, Trachurus trachurus, was reduced 2-3 logs when treated with a 3 percent-salt solution containing 0.6 ppm ozone. Ozone treatment of fresh shrimp decreased the E. coli count by approximately 2 logs.

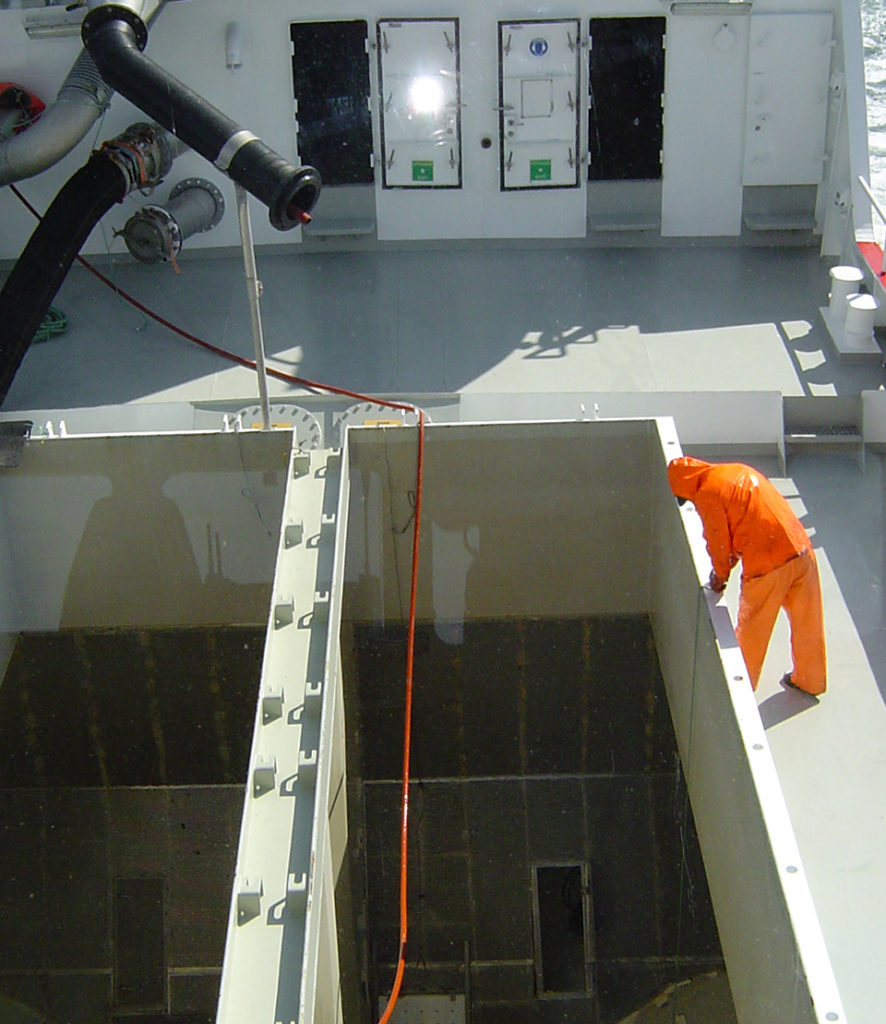

The detachment of the surface slime of Sebastes sp. rockfish aboard fishing vessels was achieved through ozonation, and continued ozonation during transport extended the shelf-life of the fish by 1.5 days. Channel catfish, Ictalurus punctatus, fillets treated with 10-ppm ozone in a tumbler had their cold-tolerant bacterial count reduced by approximately 1 log and the total coliform count cut by 0.5 log.

Ozone has been used to improve the washing process applied during the manufacture of dark-fleshed surimi. The ozone washing treatment minimized the washing time and improved color, but reduced the gel strength of the minced product. When whole and processed Penaeus monodon shrimp were respectively treated with 3.5- and 4.4-ppm ozone for 60 minutes, a 1-log reduction in total aerobic plate count was achieved in the shrimp meat, with a 1.5-log reduction in the whole shrimp.

Ozone is also effective and reproducible in its effects on both airborne and surface microorganisms. Aerial contaminants such as Bacillus sp. and Micrococcus sp. have been reduced through ozonation. Ozone in concentrations of 0.06 and 0.08 ppm destroys or reduces microorganisms on food preparation surfaces and inhibits the development of cold-tolerant bacteria and pseudomonads on foods.

In tests of various standard, molded food-processing plant gaskets, ozonated water affected the gaskets’ tensile strengths about the same as chlorine treatment. Teflon gaskets, however, were more affected by ozone than chlorine.

Process water, effluents

Significant reductions in microorganisms have been achieved when protein-containing fluids were exposed to 5- to 10-ppm gaseous ozone. Salmonella was eliminated after a contact time of seven minutes, and anthrax spores after 30 minutes. Ozone reduced the fat content in 80 to 230 ppm condensates by 96 to 98 percent and completely eliminated turbidity. The postprocess spoilage of canned food (including pasteurized products) can be decreased by using ozonated water for cooling.

Process waters can be effectively reconditioned for recycling by screening, diatomaceous earth filtration and ozonation. Significant reductions in chemical oxygen demand, total solids and microbial loads including counts of coliform bacteria and Salmonella sp. have been achieved.

Conclusion

Ozone is a potent sanitizer with promising applications in the modern seafood industry. It can be used as a safe and effective antimicrobial agent in many seafood-processing applications.

When compared to chlorine and other disinfectants, lower concentrations and shorter contact times are sufficient in controlling or reducing microbial populations. Ozone is also more effective than other disinfectants against resistant organisms such as amoebic cysts and viruses.

Exposure to ozone during processing or storage extends the shelf life of certain products while preserving their sensory attributes. Ozone does not produce significant toxic residues in the environment after treatment. Its stability and efficacy at chilling temperatures constitute attractive savings for the industry.

(Editor’s Note: This article was originally published in the October 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

George J. Flick, Jr., Ph.D.

Food Science and Technology Department

Virginia Tech/Virginia Sea Grant (0418)

Blacksburg, Virginia 24061 USA

Tagged With

Related Posts

Intelligence

Efforts to address off-flavors in RAS fish are off the charts

Researchers, feed manufacturers and recirculating aquaculture system producers are working tirelessly to ensure their fish tastes better than ever.

Innovation & Investment

Ozone increases productivity in RAS systems

Studies on improving water quality in recirculating aquaculture systems has identified ozone as an excellent solution for an optimal water environment.

Health & Welfare

Ozone treats water, disinfects aquaculture systems

Ozone is a strong oxidizing agent that effectively removes colors, odors and turbidity from water, and kills bacteria, viruses and other microorganisms.

Intelligence

In Japan, tiger puffers find themselves in hot water

A technique to farm tiger puffers in hot spring water was invented to revitalize the town of Nasu-karasuyama and is now spreading to other areas of Japan.