Power efficiency a major advantage

Biofloc technology has been successfully applied in farming tilapia in Israel, Pacific white shrimp in Belize and Indonesia, and black tiger shrimp in Australia. Commercial interest in the technology is threefold, for bioflocs provide high productivity, low feed-conversion ratios (FCRs) and a stable culture environment.

With emerging viral problems and the high cost of energy, biofloc technology appears to be an answer for sustainable production with lower operation cost. According to research by Chandaeng and co-workers in 2005 and the primary author of this article in 2006, operational costs at facilities that use biofloc technology could be reduced as much as 20 percent with FCRs of less than 1.1.

Partial harvesting has been applied in Mexico and other South American countries, as well as Indonesia. The approach aims to increase pond productivity and meet market demand for shrimp size.

The combination of the two technologies can yield even greater efficiency and pond performance.

Farm study

The authors recently carried out a study applying biofloc culture and partial harvesting at Global Group Shrimp Farm, located on the east coast of northern Sumatra, Indonesia. The farm was initially designed for pond-based flow-through culture. It had 27 ponds of various sizes, shapes and types (lined and earthen). Some of the ponds were reconstructed to modules with reservoirs for the trials.

Seven ponds were lined with high-density polyethylene plastic. Specific pathogen-free Pacific white shrimp (Litopenaeus vannamei) postlarvae were used for the study. One pond was operated as a normal phytoplankton system stocked at a density of 100 shrimp per square meter. The remaining six ponds were stocked with different densities of 145 to 280 postlarvae per square meter. The ponds were aerated with paddlewheel aerators and some with air blowers. The power input to the ponds depended on stocking density, as biofloc technology requires high aeration to keep culture water in suspension.

Very little water was exchanged throughout the culture period. During the early stages, only treated water was used to top up water loss through evaporation and siphoning. Low-protein feed with 34 percent crude protein together with grain pellets and molasses were used to increase carbon:nitrogen ratios. Strict biosecurity involving crab fencing, bird scare lines, human traffic and using filtered and treated water was enforced within the farm.

Partial harvesting started on day 85 of culture, when shrimp reached 10 grams. Further harvests were done approximately every two weeks depending on shrimp growth. Shrimp health and pond bottom conditions were checked before partial harvesting to make sure the shrimp left in ponds were in good health. Cast nests were used for harvesting without stopping the aerators.

Environmental parameters such as salinity, temperature, pH, dissolved oxygen, alkalinity and bacterial counts were monitored. The conditions were found to be within accepted industrial standards. In addition, biofloc volume was controlled at 15 ml per liter. The pond water environment became stable once biofloc was established.

Production performance

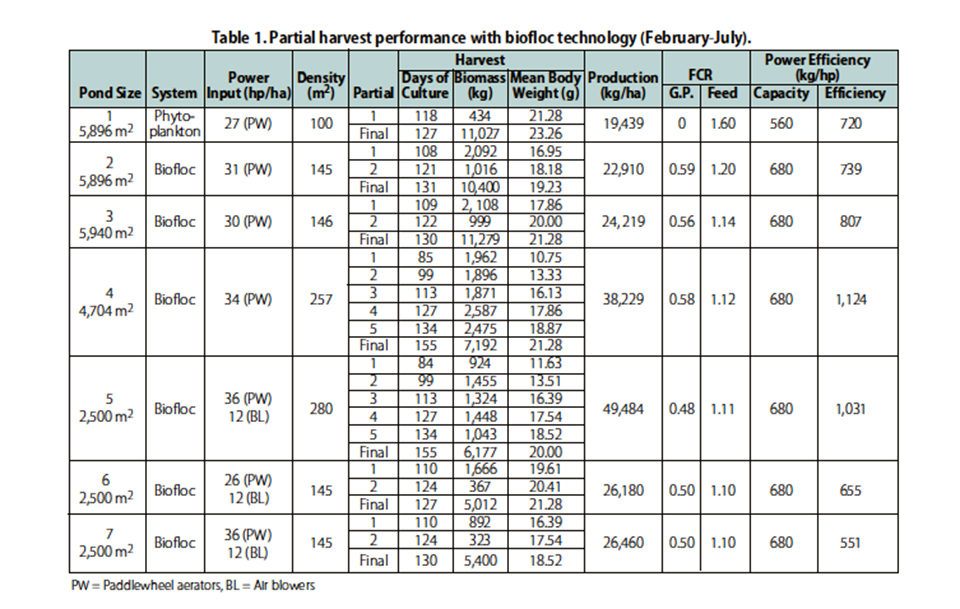

Production performance using partial harvest with biofloc technology was higher than expected (Table 1, page 88). One 2,500-square-meter pond produced 12.37 metric tons (MT) (49.48 MT/ha) through six partial harvests with a feed-conversion ratio of 1.11. Similarly, the production of a 4,702-square-meter pond through six partial harvests was recorded at 17.96 MT (38.23 MT/ha) with FCR of 1.12.

The harvest volumes of the ponds were high compared to those found by the main author in 2005, when only 25 to 35 MT/ha was achieved. In the phytoplankton-based pond system, culture FCR was 1.60. Sizes for the partial-harvested shrimp varied from under 11.0 g to over 21.0 grams.

Power efficiency

The major advantage of combining partial harvests and a biofloc system is power efficiency. The carrying capacity of biofloc systems as given by researcher Kopot and the main author is 680 kg/hp aeration. In the combined system, power efficiency increased to 1,124 kg/hp in one pond. All the biofloc ponds yielded higher production rates and lower FCRs than the pond with phytoplankton.

The study also showed a limit in productivity in two ponds (6 and 7 in Table 1) with the same stocking density but different power inputs. Increases in power input do not necessarily increase pond productivity. However, high stocking densities combined with high power inputs and partial harvests at shorter intervals increase pond productivity. In addition, partial harvesting produced shrimp of various size groups that could be controlled according to market demand.

(Editor’s Note: This article was originally published in the September/October 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Nyan Taw, Ph.D.

Senior Technical Advisor

Global Group, Indonesia

Jl. Raya Narogong Km 14 Desa Cikiwut

Bekasi 17310, Indonesia -

Hendri Fuat

Global Group, Indonesia

Jl. Raya Narogong Km 14 Desa Cikiwut

Bekasi 17310, Indonesia -

Naira Tarigan

Global Group, Indonesia

Jl. Raya Narogong Km 14 Desa Cikiwut

Bekasi 17310, Indonesia -

Kaesar Sidabutar

Global Group, Indonesia

Jl. Raya Narogong Km 14 Desa Cikiwut

Bekasi 17310, Indonesia

Tagged With

Related Posts

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Health & Welfare

Biofloc technology expanding at white shrimp farms

Biofloc technology provides high productivity, low feed-conversion ratios and a stable culture environment. Also, with viral problems and rising costs for energy, biofloc technology can help deliver sustainable production at lower cost.