Texture and water stability are important parameters to monitor

Formulated aquafeed represents about 50 percent of aquaculture production costs. The cost can be even higher if a significant portion of the feed is wasted because of poor quality.

Various methods can be used to monitor and objectively measure the quality of ingredients and aquafeeds throughout the manufacturing process. Testing of diet quality – particularly feed physical quality – tends to be more important in shrimp than in fish.

Routine testing of feed quality is an important component of feed manufacturing at the Aquatic Feeds and Nutrition program of the Oceanic Institute (OI) in Hawaii, USA. The current methods for evaluating the physical quality of shrimp diets at OI include analysis of ingredient particle size, pellet durability, pellet water stability and pellet texture.

Particle size

The particle size of ingredients has a significant effect on the physical quality of finished feed. Particle size for shrimp diets is still governed by 90 to 95 percent of ingredients passing through a 60-mesh, or 250-µ screen. At the Oceanic Institute, a reduction in ingredient particle size was found to enhance pellet durability, water stability, pellet texture, starch gelatinization and shrimp growth performance.

Particle measurement

Particle size analysis determines the fineness of feed ingredients and method of expressing their size. In shrimp feed manufacturing, the major ingredients – such as fishmeal, whole wheat and soybean meal – are normally subjected to particle size reduction. The ground ingredients are analyzed for particle size using a sifter (Fig. 1), then calculated for degree of fineness expressed as a geometric mean particle diameter.

Size factors

Particle size reduction depends upon the type of ingredient and grinding equipment (such as hammer mills or pulverizers) used. Reduction in particle size decreases the amount of air space between particles and increases the contact surface of the ingredients to allow for greater bonding during processing. The cost required to grind feed ingredients from one particle size to another varies exponentially with particle size.

Pellet durability

Pellets must be sufficiently strong to withstand subsequent processing operations. Pellet durability refers to the physical integrity of the finished feed during repeated handling and transport.

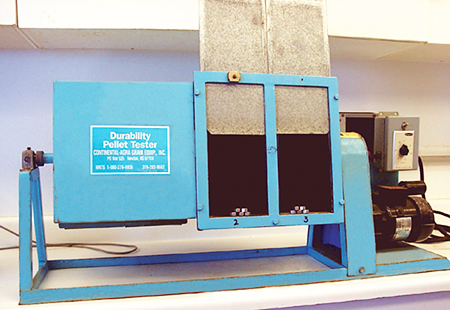

Measurement of durability

The durability of feed pellets is measured using the equipment shown in Fig. 2, by tumbling a 500-gram sample of sieved pellets (overs of sieve #10) for 10 minutes. The pellets that remain on top of sieve #10 are termed “overs.” The particles (fines, broken pellets, etc.) that pass through the sieve are called “thrus.”

The result is reported as the pellet durability index, calculated as the weight ratio of pellets after tumbling to the pellets before tumbling, multiplied by 100. This test simulates the amount of fines and broken pellets normally generated during repeated handling and transport.

Factors affecting durability

The durability or strength of pellets is determined by the nature of the ingredients in the formulation and the process used to manufacture them. Fines are generated during repeated handling, transport, and storage as the feeds move from the feedmill to the farm.

Water stability

Pellet stability measures the ability of a pellet to retain its physical integrity while in water. Pellet agitation and water movement, in addition to temperature and salinity of the shrimp culture medium, should always be taken into account during testing to obtain accurate and consistent pellet stability results.

Measurement of water stability

Three methods of pellet stability analysis – static, horizontal, and vertical shaking methods – are used at Oceanic Institute, depending on the pellet agitation and water circulation of the culture medium being simulated. The static method is basically the same as the horizontal and vertical methods with no shaking.

The horizontal and vertical methods have adjustable shaking speeds to simulate the required water movement and pellet agitation. Pellet water stability is usually determined after 1 to 2 hours of immersion in water, and calculated as the ratio of leached pellet matter to the original pellet matter multiplied by 100. Fig. 3 shows the vertical shaking method.

Factors affecting water stability

Ingredients, binding agents, coating materials, and diet formulation, preparation and processing all affect pellet water stability. Finer ingredient particles and higher degrees of starch gelatinization produce better pellet water stability.

Pellet texture

Widely used in the food industry, texture analysis is a quick and accurate method with potential as a physical quality test in aquaculture diets. Texture analyzers identify physical differences in pellets that can be used to relate texture profile with ingredient particle size, pellet durability, pellet stability and shrimp growth performance.

Measurement of pellet texture

Texture properties of shrimp pellets include fracturability, hardness, cohesiveness and compression. Recently, a test procedure for shrimp diets was developed using a texture analyzer equipped with expert software and a 5.08-cm-diameter cylindrical probe to compress pellets and generate a texture profile curve. Texture results appeared to correlate significantly with pellet water stability values.

Factors affecting pellet texture

Diet formulation and the type of processing influence the texture profile of the final pellets. The mechanical strength of pellets can be an important determinant of nutrient availability or leaching.

Conclusion

Testing the physical qualities of shrimp diets is an important component of feed-manufacturing quality-control programs. Shrimp diets should be made from ingredients of fine particle size, and tested during the manufacturing process for water stability, pellet durability and cohesive pellet texture to produce the best qualities for performance in animals. Texture analysis could be used to identify differences in pellet characteristics to develop a simple, accurate method for evaluating and predicting the physical quality of shrimp diets.

(Editor’s Note: This article was originally published in the October 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Leonard G. Obaldo, Ph.D.

Oceanic Institute

41-202 Kalanianaole Highway

Waimanalo, Hawaii 96795 USA

Tagged With

Related Posts

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Aquafeeds

Enteromorpha tested as shrimp feed ingredient

With vitamins, minerals, carotenoids and higher protein content than other species, Enteromorpha is a superior seaweed choice and a potential shrimp feed ingredient.

Aquafeeds

Extruded shrimp feeds reemerge

The process for making extruded shrimp feeds has flexibility to produce diets with a wide range of fat levels, densities, shapes and sizes.

Health & Welfare

Nutrient requirements of penaeid shrimp

Penaeid shrimp need the same nutrients required by all animals, including protein, lipids, energy sources, vitamins, minerals, oxygen and water.