Project revealed knowledge in terms of genetics, physiology, biology and water quality

Due to high market demand, low wild catches and a continuing increase in prices, the European lobster (Homarus gammarus) is one of the more promising candidates for closed-cycle and controlled aquaculture. In 2000, Norwegian Lobster Farm A.S. initiated an extensive research and development project on the European lobster in cooperation with the Institute of Marine Research in Bergen, the International Research Institute of Stavanger and the University of Stavanger.

The research facilities were located on Kvitsøy, an island on the southwestern coast of Norway. The project included work on biology, technology, feed, markets, monitoring of water quality, health management and studies that compared single cages to communal rearing systems. The primary aim of the project was to explore the potential for producing European lobsters in land-based facilities using recirculation of seawater.

The project achieved semi-commercial production of 2 metric tons (MT) annually. Due to a lack of private investment and inadequate public funding in Norway, however, the project never came to commercial production levels. New initiatives were taken to establish pilot production in artificial seawater in Medina del Campo, one hour’s drive northwest of Madrid, Spain, and in Iceland, which offered geothermal water sources. The Icelandic project has now received grants from the Icelandic Research Council and Nordic Innovation to develop the steps for commercialized land-based recirculating aquaculture of lobsters.

Geothermal fields in iceland

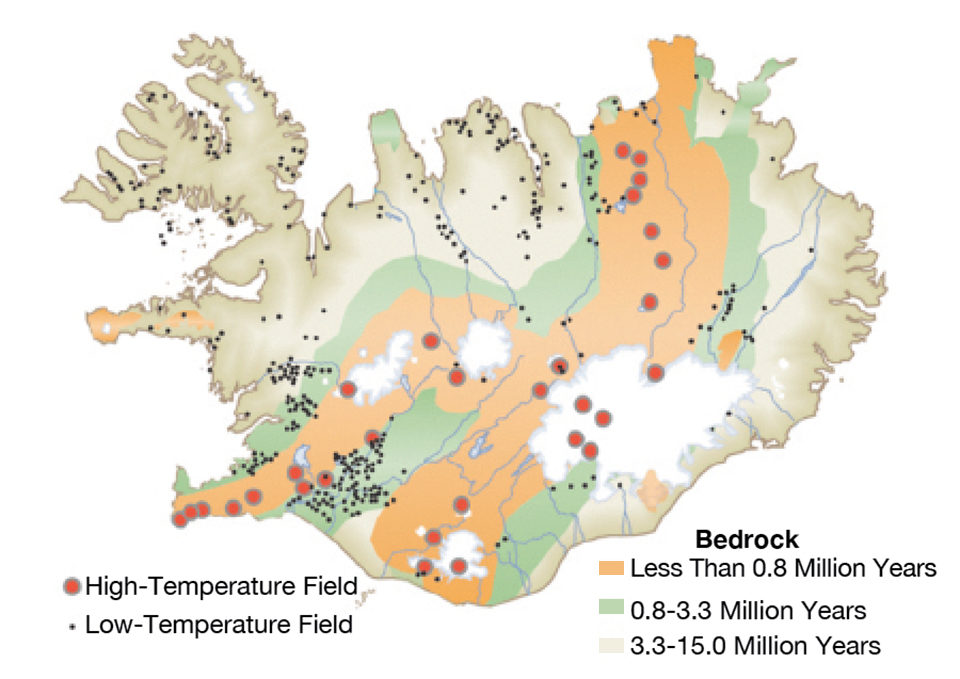

The geothermal areas in Iceland are bound to one of the earth’s major fault lines, the boundary between the North American and the Eurasian tectonic plates known as the Mid-Atlantic Ridge. The two plates are moving apart at an average rate of 2 cm/year. This creates a “hot spot” of great volcanic productivity with volcanoes and hot springs. Fig. 1 shows the active volcanic zone through the country from the southwest to the northeast.

The geothermal areas are divided into so-called high-temperature areas with more than 200 degrees-C at 1,000 meters depth and low-temperature areas with less than 150 degrees-C at 1,000 meters depth. The high-temperature areas are located in the active volcanic zone, and the low-temperature areas mostly flank the active zone.

Seven geothermal power plants in Iceland produce electricity and hot water/steam for house heating and/or industry. Moreover, more than 250 district heating systems operate in Iceland. At 48 and 37 percent, space heating and generation of electricity are the greatest users of geothermal energy. Fish farming and greenhouses account for a total of 8 percent – a figure that could be increased substantially, producing sustainable high-quality food and health products for export by direct use of renewable energy.

Lobster aquaculture

Lobster aquaculture can be conducted in four different forms: resource/wild stock enhancement, sea ranching, product enhancement and full grow-out. Focus on the resource enhancement aspect began more than a century ago, and many hatcheries were built in Europe and North America to hatch eggs and release larvae into the wild.

In product enhancement, lobsters are kept in holding ponds and fed until their quality or prices increase. Sea ranching ensures exclusive, licensed property rights for companies to stock and harvest lobsters in a restricted area. Full grow-out or closed-cycle culture is independent of fisheries and involves rearing lobsters from egg to market size.

The attention to full grow-out culture peaked in the 1970s, when government-funded research programs on intensive culture of American lobsters were conducted in the United States and Canada. As a result of this research and earlier studies, lobster biology is reasonably well understood. Seedstock can be produced on demand, and systems and strategies are in place for rearing lobsters from larvae to market size.

Several private companies in the United States started lobster production, but none of these projects proved commercially viable. A large increase in landings of wild lobsters and an abrupt termination of governmental research programs before rearing technology and formulated lobster feeds were sufficiently developed contributed to this scenario.

In addition, the computer and automation technology available in the 1970s and 1980s was insufficient to achieve automation at reasonable costs. However, during the 1990s, significant breakthroughs in automation and land-based aquaculture technology – especially recirculation – yielded major progress toward more economical production.

European lobsters

Compared to other lobsters, the Homarus species are considered very hardy with a simple and abbreviated larval period. They feed readily on natural and artificial feeds, are resistant to disease and exhibit very rapid growth in warmed water. Thus, temperature is the primary controller of growth, with optimum water temperature found to be 20 to 22 degrees-C. The larval period in 20 degrees-C water is around 12 days, compared to 35 days at ambient temperature.

H. gammarus can reach sizes of 250 to 300 grams (total length 210 mm, carapace length 75 mm) in 24 to 30 months as long as constant 20 degrees-C water is provided. The difference in growth rate experienced in heated seawater is a result of removing winter growth inhibition and allowing year-round growth and molting.

Culture system design

Because of large growth variations and high losses due to cannibalism and injuries when kept communally, the cultured lobsters have to be kept in individual containers. The ideal system for rearing lobsters individually should be relatively inexpensive to construct and operate, simple to maintain and based on automatic feeding and self-cleaning. It should maintain ideal water quality conditions, enable high densities, conserve water at high temperatures, ensure good survival and permit easy access to the livestock for inspection and feeding.

So far, no systems have successfully incorporated all of these features into a single design except for the patented Norwegian Lobster Farm concept. Communal rearing has been used to grow out juveniles, but due to uneven growth rates and high mortalities, the practice is not recommended in intensive culture. This may, however, be a method for producing predator-trained small juveniles for release.

The technology developed by Norwegian Lobster Farm provides each lobster with an individual compartment with a sea view, a constant supply of oxygen-saturated seawater and methods for providing food and removing solid and dissolved wastes. In general, the culture environment should promote rapid, uniform growth and high survival.

Iceland project

Iceland has incredible opportunities to increase sustainable food production through its access to clean water, land and renewable energy. In the Norwegian work with lobsters, energy represented 10 percent of the operational costs, next after salaries and feed costs. Given access to cheap geothermal energy sources, the cost for heating water with electricity can be removed. This savings would compensate for the extra shipping costs due to Iceland’s remoteness from main markets.

Aquaculture of new high-value species is probably one of the better opportunities in Iceland, but also a challenge, as the island is small and has limited competence in recirculation systems. Iceland is also relatively far from main markets.

As land-based farming of lobsters is a high-risk process, there is a need to establish an economically beneficial site and build up competence in lobster farming before taking large steps in upscaling.

A review of preferable sites in Iceland was carried out by Svinna-Engineering and Norwegian Lobster Farm in 2013. The results identified the Reykjanes Peninsula in southwestern Iceland as the most interesting area to build a land-based lobster farm.

Perspectives

Norwegian Lobster Farm established the European Lobster Centre of Excellence (ELCE) in 2013 in to coordinate research and development, funding and knowledge sharing among producers. ELCE now has 13 members from seven countries in Europe. The Icelandic project is a strategic spin-off from the ELCE consortium. The main aim of the project in Iceland is to eliminate biological and technical risk factors before taking the next steps toward commercial land-based farming of European lobsters. Of special concern are the low survival rates, which can be down to 10 percent, in the first life stages. On the other hand, anecdotal information has indicated that up to 90 percent survival can be obtained with the use of high-quality broodstock and farming methodologies.

The Iceland project will reveal more knowledge in terms of genetics, physiology, biology and water quality in order to fully understand the mechanisms and factors that promote high survival. Furthermore, the technical design of future lobster farms needs to be optimized based on the extensive practical experience from the Kvitsøy project. Success in Iceland could serve as a stepping stone toward expansion of lobster farming in Europe, possibly taking advantage of the low-temperature geothermal fields widely found in many countries.

(Editor’s Note: This article was originally published in the May/June 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Asbjørn Drengstig

Norwegian Lobster Farm Ltd.

P. O. Box 391

4067 Stavanger, Norway

ad@norwegian-lobster-farm.com -

Ragnheidur Thorarinsdottir

Svinna-Engineering Ltd.

Reykjavik, Iceland

Related Posts

Innovation & Investment

Competitiveness comes at scale for RAS operations

Total RAS salmon production worldwide is less than half of 1 percent of total production. Many of the investors flocking to the sector now are new to fish farming, and confident in its potential.

Innovation & Investment

Matorka aims to unearth innovation with Arctic charr

A new and ambitious Iceland company is about to construct what it claims will be the world’s largest land-based salmonid farm. What sets Matorka’s Arctic char farm apart is its ability to tap into natural resources unique to the island nation.

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Innovation & Investment

Polish RAS salmon farm mixes modern technology with ancient water

Jurassic Salmon, established in Poland just two years ago, is using 150-million-year-old geothermal saline waters from the “Lower Jura” era. Armed with certifications, the company is navigating an awkward growth stage.