Norwegian Lobster Farm tests, documents 6 culture technologies

The European lobster (Homarus gammarus) is one of the most valued seafoods in the world, and has a worldwide market. The lobsters are relatively easy to rear in aquaculture, and their biology is fairly well understood.

The main limitation for lobster aquaculture has been high production costs, due to the demand for 18 to 22 degrees-C water to get acceptable growth rates, and the need for individual rearing compartments to avoid cannibalism and uneven growth rates due to hierarchies. The lack of high-quality formulated feed has also been a limiting factor.

However, during the last decade, rising lobster prices and the development of new recirculation technology have made lobsters a more promising candidate for closed-cycle aquaculture. In addition, a new law that ensures property rights for sea-ranched lobsters has promoted an opportunity to mass-produce lobster juveniles for sea ranching.

Kvitsøy lobster hatchery

The only lobster hatchery in Norway is located on the island of Kvitsøy in southwestern Norway. In 2000, a project was initiated by the company Norwegian Lobster Farm to evaluate the potential for commercial production of plate-sized lobsters of 20-cm length and 300-gram weight. All trials were conducted on a rather small scale in order to reveal and solve the main biological, technical, and market bottlenecks before commercializing.

Lobster-rearing technology

The ideal system for rearing lobsters individually should be relatively inexpensive to construct and operate, simple to maintain, and based on automatic feeding and self-cleaning of tanks and cages. It would also need to maintain ideal water quality conditions, enable high densities, conserve water at high temperatures, ensure good survival, and permit easy access to the livestock for inspection and feeding.

Norwegian lobster farm

American researchers reported in 1995 that no successful designs included all of these features in a single design. During the last five years, however, Norwegian Lobster Farm tested and documented six different technologies for lobster culture with the aim of developing cost-effective farming solutions using recirculation of heated seawater. As a result of this work, Norwegian Lobster Farm patented farming technology that incorporates all the necessary prerequisites for successful culture into a single farming unit.

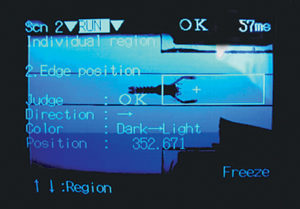

In addition, robots now supplement most of the procedures that previously were dependent on manual labor. The concept includes the use of robots for the classification of larval stages, feeding, and harvesting. Image-processing software is used to identify molts, mortality, and the time for harvesting.

The farming concept has been successfully tested over the last nine months. The company is now commercializing the results and will soon start building the first large-scale lobster factory in Europe on the island of Kvitsøy.

Feed development

Norwegian Lobster Farm has also developed a formulated feed especially engineered for European lobsters (Table 1). In initial feed trials, all lobsters were fed ordinary cod feed. As a result, most lobsters had pale pigmentation due to the lack of pigment in this feed.

Drengstig, Chemical composition and nutritional content of feed, Table 1

| Ingredient | Percentage |

|---|---|

| Protein | 54.7 |

| Lipid | 15.6 |

| Carbohydrates | 13.6 |

| Ash | 9.5 |

| Water | 6.8 |

| Energy (MJ/kg) | 21.6 |

It was easy to observe the changes that occurred in shell color and thickness after introducing the new lobster feed. After the first and second molting, the lobsters turned from white to blue and finally black.

Norwegian Lobster Farm has now produced the first plate-sized lobsters raised solely on a formulated diet (including the larval stages) for two years. The feed-conversion ratio was within the range of 1.00 to 1.14 kg feed per kilogram weight gain.

Water quality

The desirable levels of water quality for clawed lobsters are temperatures of 18 to 22 degrees-C, salinity of 28 to 35 ppt, greater than 6 mg oxygen per liter, pH of 7.8 to 8.2, and less than 14 µg nitrogen per liter as un-ionized ammonia. For short periods, lobsters tolerate considerably lower oxygen and higher ammonia concentrations than indicated as desirable.

Ammonia concentration is the most limiting parameter in recirculation systems for seawater. At Kvitsøy, the biofilter efficiently removes total ammonia nitrogen (TAN) at rates of 50 to 70 percent. In initial tests, concentrations of unionized ammonia in the tanks were in the 0 to 5 µg nitrogen per liter range. Due to low biomass loading, only a minor part of the biofilter’s capacity was utilized. Lobster feed is high in protein, and the ammonia excretion rates in the animals are correspondingly high. Average rates of 0.1 to 0.5 grams TAN per kilogram per day have been reported for adult lobsters.

(Editor’s Note: This article was originally published in the February 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Asbjørn Drengstig, M.Sc.

Norwegian Lobster Farm Ltd.

P. O. Box 391

4067 Stavanger, Norway[109,111,99,46,109,114,97,102,45,114,101,116,115,98,111,108,45,110,97,105,103,101,119,114,111,110,64,103,105,116,115,103,110,101,114,100,46,110,114,111,106,98,115,97]

-

Dr. Asbjørn Bergheim

RF-Rogaland Research

Stavanger, Norway

Tagged With

Related Posts

Aquafeeds

A look at phospholipids in aquafeeds

Phospholipids are the major constituents of cell membranes and are vital to the normal function of every cell and organ. The inclusion of phospholipids in aquafeeds ensures increased growth, better survival and stress resistance, and prevention of skeletal deformities of larval and juvenile stages of fish and shellfish species.

Responsibility

Hatchery production of spiny lobsters

Spiny lobsters are a premium seafood whose culture has depended on wild-caught seedstock. An Australian company is helping shift the farming paradigm to more sustainable hatchery production.

Responsibility

Advancing the ecosystem services of aquaculture

The Nature Conservancy was inactive in aquaculture until new program leader Robert Jones joined. His focus is on the positive outcomes of responsible aquaculture.

Innovation & Investment

Aquaculture Exchange: Bill Herzig

The Global Aquaculture Alliance will honor seafood procurement expert Bill Herzig with a Lifetime Achievement Award during its annual GOAL conference. He talked to the Advocate about top-to-bottom commitment to sustainability and the ambitious lobster aquaculture project he spearheaded in Malaysia with Darden Restaurants.