Mariculture techniques can be used for stock enhancement, commercial bait and food production

In the late 1990s, increased demand and high value for bait shrimp in the United States prompted interest in the market potential of farm-produced bait shrimp and the technology needed for its commercial development. The authors were since contracted to develop hatchery techniques for producing Florida’s native pink shrimp (Farfantepenaeus duorarum) for the Crystal River Mariculture Center (CRMC).

CRMC is a multispecies marine hatchery designed to produce juvenile populations for stock-enhancement programs. The facility was established in Crystal River, Florida by Florida Power Corp. (Progress Energy) as part of a negotiated mitigation settlement with the U.S. Environmental Protection Agency. The CRMC complex includes a two-story, 752-square-meter hatchery building and eight 0.4-ha ponds.

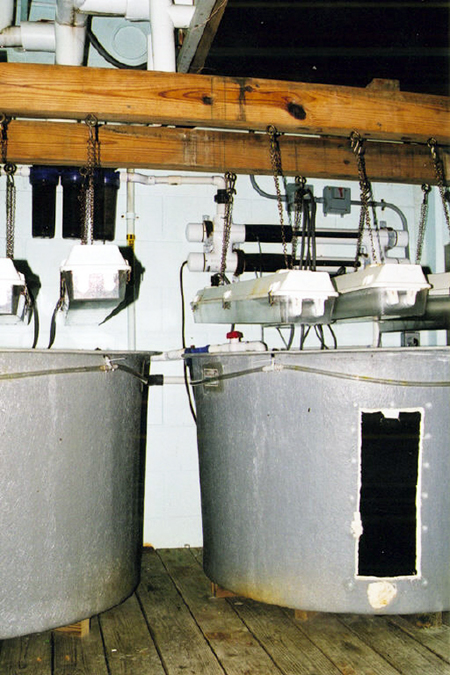

The hatchery building includes a water-chemistry laboratory, four spawning rooms, incubation tank room, algae-production room, and administrative spaces. Each spawning room contains two 3.6-meter-diameter recirculating tanks. The recirculating system includes a biological filter for the removal of dissolved waste products, a sand filter for removal of particulate matter, and an ultraviolet filter for pathogenic bacteria control.

Broodstock collection

Fifty-four pink shrimp (31 females and 23 males) were collected 12 miles off the coast of Fort Myers, Florida in the Sanibel fishing grounds during the last week of April 2001. The females ranged 11.3 to 57 grams in size, with various stages of ovarian development. Sizes for the males, which had good spermatophores, ranged 11 to 32 grams.

Maturation tanks

After additional males were collected from a Crystal River bait shop, the brood-stock were stocked in the maturation tanks at three to eight animals per square meter, depending on the shrimp size, at a sex ratio of 1:1. The tanks were supplied with filtered, recirculating, 30-ppt oceanic water with temperatures maintained at 27 to 29 degrees-C and pH of 8.0 to 8.2. Photoperiod was set for 10 hours of light and 14 hours of darkness.

Mating

Mating in shrimp with a closed thelycum usually takes place at night. A male with a hardened shell will mate with a female that has just molted and is still soft. The male inserts up to two sperm packets into the female’s seminal receptacle. The female will carry the sperm packets internally until she spawns or molts again.

Ablation and feeding

Large females were selected for unilateral eye enucleation under water, by incising and crushing the eyestalk. Maturation feed based on 10 percent body weight was comprised primarily of squid, with additional frozen enriched artemia and commercial maturation pellets. The typical feeding schedule applied artemia at 8 a.m., squid at 1 and 5 p.m., and a small amount of pellets from an automatic feeder over a 12-hour period.

Spawning

Four 1.1 x 1.1 x .25-meter polyethylene tanks held the spawning females. The tanks were filled with filtered, ultraviolet-sterilized seawater. Aeration and a heater set to 28 degrees-C were placed in the water to maintain optimal spawning temperatures and dissolved-oxygen levels.

Stage 3 and 4 females were placed in the spawning tank in the morning. Stage 4 females normally spawned by 1 to 2 p.m. When spawning occurred, females were removed immediately to the maturation tank, and a stage 3 female was moved to another spawning tank. The stage 3 females usually spawned overnight or during the following afternoon.

Larval rearing

Eggs were removed immediately upon spawning or as soon as possible the following morning to be washed, disinfected, counted, observed under a microscope for viability, and transferred to the larval-rearing tanks.

Larval rearing was based on the “clear water” method developed in the 1970s at the Galveston Laboratory of the National Marine Fisheries Service in Texas. The method has been successfully adapted to local conditions and is implemented throughout the Western Hemisphere. Nauplii were stocked at 100 per liter in 1.22-meter-diameter tanks.

Larviculture procedures

The larval-rearing tanks were filled with UV-sterilized water, Chaetoceros gracilis diatoms at an initial density of 20,000 cells per milliliter, and inorganic nutrients for growing microalgae. Light aeration with airstones and water temperature of 28 degrees C were maintained throughout. Specific steps for the larval stages are presented in Table 1.

Dixon, Management steps for different larval stages of F. duorarum, Table 1

| Larval Stage | Procedures |

|---|

Larval Stage | Procedures |

|---|---|

| N1-N4 | Maintain algae counts of 50,000 100,00 cells/ml. |

| Protozoea 1-2 | Add more algae if the count falls below 300,000 cells/ml. |

| Protozoea 3 | Add more algae if the count falls below 300,000 cells/ml. Check larvae for fecal strands. |

| Mysis 1 | Maintain 300,000 cells/ml Chaetoceros. Begin feeding artemia and larval “Z.” Exchange 50% of water. |

| Mysis 2-3 | Maintain 300,000 cells/ml Chaetoceros, increase artemia, and continue feeding larval “Z.” Exchange 50% of water. |

| PL1 | Maintain 300,000 cells/ml Chaetoceros, decrease artemia, and continue feeding larval “Z.” Exchange 50% of water. |

PL2 were harvested from the tanks by siphoning water into a collecting bucket equipped with a 350-μ mesh filter. Filtered, sterilized seawater was added to clean the PL and eliminate excess algae and debris.

Production

Twelve ablated females produced 2.35 million nauplii over a two-month period. One 57-gram female, easily recognized by an injured uropod, spawned seven times and produced 737,818 nauplii. Survival rates from N1 to PL2 averaged 45 percent.

Conclusion

Recent assessments of Gulf and South Atlantic penaeid stocks suggest they are harvested at or slightly in excess of maximum sustainable levels. Indices of juvenile shrimp from the Gulf Coast reflect a steady decrease in abundance.

This decrease could result from loss of nursery habitat from coastal development and commercial harvesting of prespawning juveniles for live bait. Mariculture techniques can now be used to culture pink shrimp for stock enhancement as well as commercial bait and food production.

(Editor’s Note: This article was originally published in the April 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

-

Frank Whitney

Mariculture, Inc.

P.O. Box 189

Terra Ceia, Florida 32450 USA

Tagged With

Related Posts

Health & Welfare

Biofilms improve nursery culture of pink shrimp in Brazil

In trials examining attachment of biofilm to different substrates, authors measured their influences on the survival and growth of pink shrimp postlarvae.

Intelligence

Shrimp processing byproducts find many uses

Shrimp processing byproducts are constructively used in shrimp or fish feeds, livestock feeds and plant fertilizer. Chitin from shrimp exoskeletons is used in bandages and varied cosmetic products.

Health & Welfare

New Bacillus probiotic tested for shrimp

The authors evaluated Bacillus bacteria in a pink shrimp nursery and found it controlled Vibrio concentrations as well as a commercial probiotic.

Aquafeeds

Feed Innovation Network: A streamlined aquafeed ingredient evaluation tool

To position aquaculture for future growth, it needs tools to evaluate a growing spectrum of alternative ingredients and formulated diets designed to optimize fish health and efficient production.