Process avoids hormone usage and maintains strain purity in genetically normal males

The most successful sex-reversal and breeding program with the greatest economic impact in tilapia farming has been the production of all-male XY populations of Nile tilapia from YY males. In 2001, biologist Dr. Graham Mair concluded that YY male technology provides a robust and reliable solution to the serious and widespread problems of early sexual maturation, unwanted reproduction and overpopulation in tilapia culture.

In countries like Mexico and Ghana, mixed-sex tilapia populations are employed mainly in some fisheries restocking programs and small-scale, basic aquaculture operations. Monosex all-male tilapia progeny grow faster and to larger sizes than females.

To date, the establishment of all-male tilapia has been achieved through manual sexing, hybridization, hormonal sex reversal or YY male tilapia technology. All these technologies have advantages and disadvantages in their application, and only hormonal sex reversal has become widely used worldwide.

Natural YY male tilapia

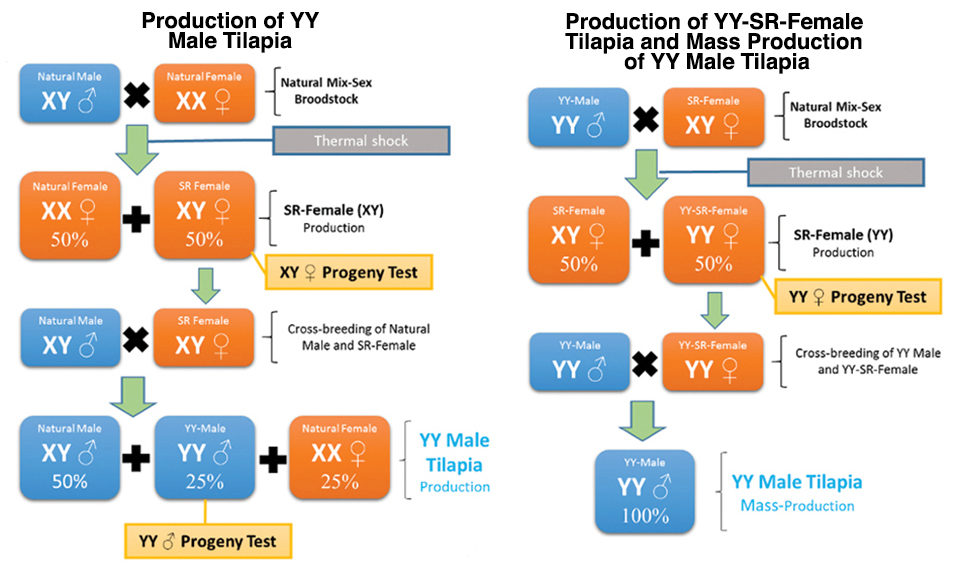

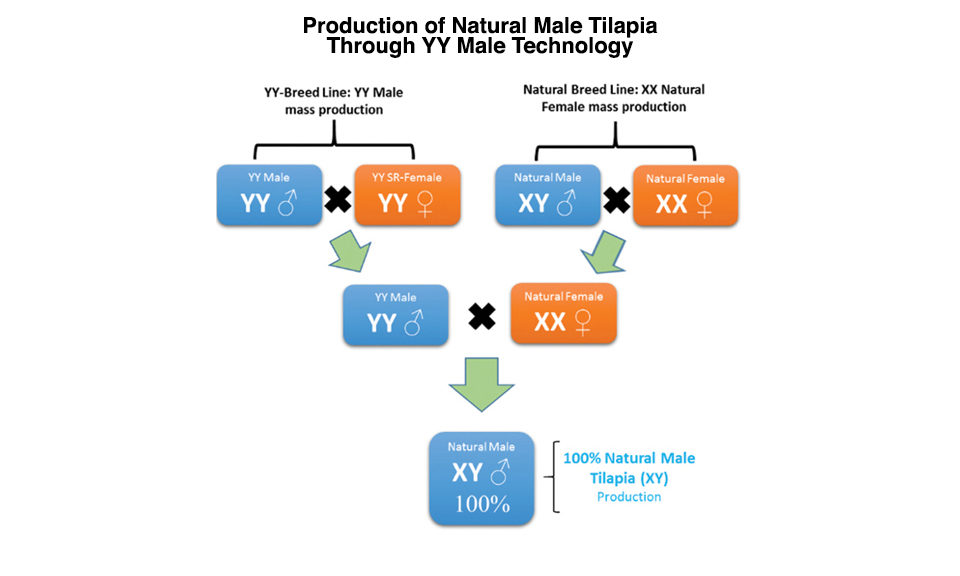

The YY male tilapia technology is based on the genetic manipulation of sex. This is achieved through a combination of feminization and progeny testing to identify the novel YY genotype (Figure 1) that sires only XY natural male progeny (Figure 2) or natural male tilapia. However, the occurrence of occasional females/males can occur from the action of several autosomal sex-modifying genes. Feminization of the YY genotype is a vital step in the development of the YY technology on a large scale, as it makes possible the production of YY males without the need for time-consuming progeny testing.

Feminization (XY females) can be achieved through gynogenesis by irradiation and hormonal sex reversal or thermal treatment. However, although not always feasible with all strains of tilapia, sex reversal thermal treatment has proven to be a more desirable method to produce XY females in large-scale operations, as it avoids the employment of hormones at any stage of the production process.

This is especially important when producing tilapia in countries where the use of hormones is prohibited in the production of food products. Also important is the increasing interest of major markets for sustainable and environmentally friendly food sources.

Progeny testing XY females with normal XY males should spawn 75 percent males (25 percent YY and 50 percent XY), and 25 percent XX females result from the XY-XY mating. Male progeny from this mating are then grown for a second generation for progeny testing. When the YY males are test crossed with normal XX females, 100 percent XY male progeny result.

YY technology benefits

In 1997, Mair and fellow researchers described the important comparative advantages and disadvantages of the YY male technology as a means for mass production of monosex male tilapia, as compared to other commonly used alternatives such as manual sexing, hybridization and sex reversal. One of the biggest advantages of using the YY technology is that its masculinization effect always works. Another advantage is that these all-male populations consist of completely normal XY males.

The technology is safer for farm operators because it avoids the health risks associated with the use and handling of hormones. Hormones can be harmful to humans if swallowed or absorbed through skin and/or inhalation, and have a danger of cumulative effects. The commonly used hormone methyltestosterone (M.T.) is considered carcinogenic and can cause liver damage or interfere with normal reproductive functions in humans and animals.

YY male technology is safer for fish and results in greater fingerling survival rates, as it avoids the health risks associated with hormone usage. Work in 2011 by Dr. Miguel Rubio Godoy and co-workers and 2001 research by Gina Conroy described the negative impacts of M.T. treatment in fingerling survival rates due to higher levels of ectoparasitic, fungal and bacterial infestations as a result of the suppression effect on the fish immune systems.

The use of YY technology prevents many environmental impact risks that hormone residues in the production water, units and system waste could have. It also reduces ecological impacts on wild populations when farmed stocks are released through restocking programs and/or accidental escapes.

The release of hormone sex-reversed tilapia in the wild consists of 50 percent males with XX chromosomes. The next generation in the ecosystem will have a very high female ratio. The natural balance of sexes in the ecosystem will change dramatically, a situation the local fisherman will dislike, as they will catch only very small fish. This problem is worldwide. For example, Mexico invests millions of dollars in restocking programs with hormone sex-reversed tilapia (males with double X chromosomes). Large escapes from culture in places like Lake Volta in Ghana can change the sexual balance of natural tilapia populations.

Compared to M.T. treatment, it is a more consistent and reliable technique that achieves over 95 percent male offspring, while it is not rare to see male ratios below 90 percent for hormonal treatment. The YY approach promotes offspring heterosis or hybrid vigor, as the technique requires keeping two different lines between the male (YY) and female (XX) broodstock.

Finally, increased interest by major markets worldwide – particularly in Europe and recently in the United States – for environmentally friendly and sustainable food sources. The application of hormones to fish destined for human consumption is prohibited in the European Union under a formal European Commission directive, which also prohibits the importation of animal products produced with hormones.

Perspectives

The YY male technology provides a robust and reliable solution to the problem of early sexual maturation, unwanted reproduction and overpopulation in tilapia culture, and can increase production of tilapia by 50 percent.

The technique can be considered environmentally friendly, as no hormones are applied to fish at any stage of the production process. Species and strain purity are maintained, and the fish produced for culture are normal genetic males. Although the development process is time-consuming and labor-intensive, once developed, the production of monosex males can be maintained through occasional feminization of YY genotypes.

Provided that broodstock purity is maintained, YY male technology can be applied in existing hatchery systems without special facilities or labor requirements. Discounting the initial development costs, additional costs for application of this technology at the hatchery level are minimal, while the potential economic advantages to growers can be considerable.

(Editor’s Note: This article was originally published in the March/April 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Dr. Adrian G. Hartley-Alcocer

Sustainable Aquaculture

P/O Bong 20

5941NL Velden, The Netherlands -

Dr. Eric N. Bink, M.S.

Til-Aqua International Ltd.

Someren, The Netherlands

Tagged With

Related Posts

Innovation & Investment

Large-scale tilapia project driving aquaculture development in Ivory Coast

A large-scale aquaculture project in Ivory Coast, with "soft technology" adopted by Societe d’Elevage et de Distribution de Poissons, allows the full growing cycle to be controlled using local materials, manpower and inputs.

Intelligence

Bangladesh’s tilapia aquaculture industry shows resilience

Tilapia aquaculture in Bangladesh has developed significantly since 1999, based on the Genetically Improved Farmed Tilapia (GIFT) strain of Nile tilapia (Oreochromis niloticus) introduced from Malaysia and on the significant genetic improvement research work by the Bangladesh Fisheries Research Institute (BFRI).

Intelligence

There’s more than one way to grow tilapia

Tilapia aquaculture has expanded significantly in the last 30 years. Production systems range from extensive, low-density and low-technology in small earthen ponds, to semi-intensive systems in larger ponds, to recirculating systems with high densities.

Responsibility

Optimizing tilapia biofloc technology systems, part 1

Chambo Fisheries, the world’s largest tilapia biofloc tank farm and the largest tank farm in Africa, has a multi-cohort, sequential, continuous production schedule.