Effects of time and temperature on pellet water stability

The effects of long steam conditioning times of up to 30 minutes on the water stability of shrimp feeds wereevaluated in early research studies. The results obtained indicated no advantage due to long-term conditioning, but researchers recommended increasing conditioning temperatures beyond 80 degrees-C. Other research work using a two-stage, three-meter conditioner reported a 27.5 percent increase in starch gelatinization at high temperature (82 to 93 degrees-C), compared to an 11 percent increase for lower temperatures (71 to 80 degrees-C).

Multistage preconditioners

Aquaculture feed manufacturers in Asia precondition shrimp mash feeds using retention times of up to three minutes and temperatures of 90 to 95 degrees-C prior to pelleting. To achieve residence times in excess of two minutes, they use conditioners with two or, more commonly, three stages.

Long residence times in the conditioner are needed toallow steam to condense and transfer its moisture and energy to the mash. More importantly, water needs time to be absorbed and cause swelling of starch granules. Without enough time in the conditioner, unabsorbed water causes the mash to be too slippery, resulting in die plugging.

Moisture penetration and gelatinization

Research work done in 1989 showed that longer residence time permitted total penetration of moisture (withmore heat transfer to the mash), increased gelatinization of the starches for better binding, and achieved greater water stability. Similarly, later research in 1991 indicated that preheating mash allows faster and better penetration of steam into the product and improved gelatinization of starch granules.Another researcher reported in 1991 that only 20 percent starch gelatinization could be obtained without preconditioning the mash.

Steam and moisture

When considering the thermal conductivity of feed particles, moisture has the greatest impact. Injection of steam alone in the conditioning chamber has limited effect on the swelling properties of starch. However, when water is added in the preconditioning chamber, the amount of steam injected per unit of starch has a dramatic impact on starch gelatinization.

Most of the studies where water was added to the pre-conditioner reported final mash moisture contents of 25 to 40 percent – too high to be applicable in a pelleting process where plugging of the die occurs at 16 to 18 percent.

In other recent research trials with double- and triple pass conditioners, results indicated that the highest starch gelatinization and water stability were attained for pellets processed at 90 or 95 degrees-C at 270 seconds of retention time. Data also indicated that as retention time increased, temperature had the greatest impact on water stability. Further research is needed to determine the effects of dwell times greater than 270 seconds.

Gelatinization and hydrostability

Also, correlation coefficients indicated there were strong relationships between percent starch gelatinization and water stability (r = 0.88, P = 0.02). Similarly, Ryu and coworkers (1994) reported a strong correlation (r = 0.85) between water stability and degree of cooking. Water stability was also found to be highly correlated (r = 0.96, P <0.01) with weight gain and feed conversation (r = 0.89, P =0.02). Thain and Urich (1972) attributed optimal performance of plaice fish (Pleuronectes platessa) to the high waterstability of feed containing guar gum and hydroxypropyl cellulose binders.

Preconditioning temperature, pellet structure

Micrograph photographs of pellets conditioned at increasing temperatures for 270 seconds in a preconditioner make it easier to visualize differences in the pellets’ structure due to processing conditions.

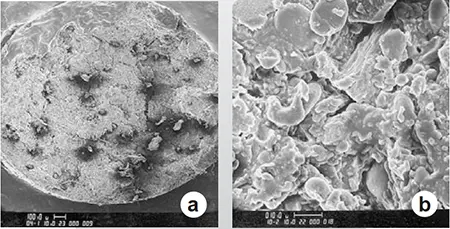

Pellets produced at 80 degrees-C

b: Pellet core, 80 degrees C (1,000X magnification).

Fig. 1A is a 40X micrograph of a feed pellet produced at 80 degrees-C. Fig. 1B is the micrograph of the same pellet at 1,000X magnification. At 40X, the pellet structure appears jagged and there is indication of a somewhat open structure. Fig. 1B clearly shows open areas, indicating thereis incomplete contact between the particles.

Fissures appear to create separation between adjacent particles. Some starch granules appear swollen, but the protein portion does not seem to diffuse with or around thes tarch granules. The fissures provide an opportunity for water penetration, which is probably why the mash conditioned at this temperature had very poor water stability.

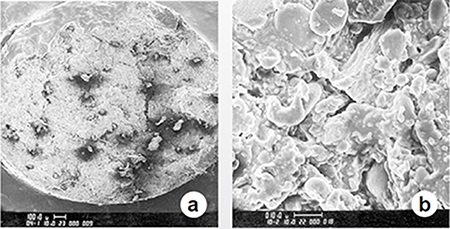

Pellets produced at 90 degrees-C

b: Pellet core, 90 degrees C (1,000X magnification).

Figs. 2a and 2b are micrographs of a pellet produced at 90 degrees-C. At low magnification (Fig. 2a), the surface appears smooth and compact. Higher magnification (Fig.2b) shows what appears to be melting protein merging with or around starch. Some starch granules are swollen and inclose contact with the protein matrix.

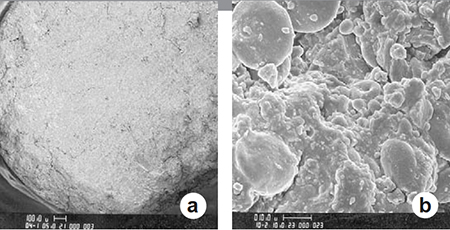

Pellets produced at 95 degrees-C

b: Pellet core, 95 degrees C (1,000X magnification).

Figs. 3a and 3b show a pellet produced at 95 degreees C. In Fig. 3a, the surface appears very smooth, compact, andwith fewer cracks along the surface than in Figs. 1 and 2. Fig. 3 shows a very fused structure. Some of the starch granules appear embedded or cemented in the protein matrix. In some cases, it is difficult to distinguish between the starch granule and the protein matrix.

Preconditioning temperature, pellet hydrostability

Increasing temperature apparently increases flow and diffusion of protein. The result of this diffusion is a continuous phase with a very tight structure that helps to prevent water penetration. The interaction between starch damage and protein could be major factors in producing high-quality, water-stable pelleted feeds.

Conclusion

Based on the research work described above, shrimp mash feeds should be preconditioned at temperatures greater than 90 degrees-C for at least 90 seconds, to produce percent shrimp pellets with high water stability.

(Editor’s Note: This article was originally published in the December 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

Preconditioning shrimp feeds, Part 1

To obtain highly water stable pelleted feeds, the mash should be preconditioned for more than 90 seconds at temperatures higher than 90 degrees-C.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Preconditioning is crucial in aquafeed manufacturing

Preconditioning is an important step in the manufacturing of aquafeeds, because it increases the moisture content and temperature of ingredient meal particles, which is key to reach a high water stability desired in aquafeeds. Pre-conditioner efficiency requires consistent particle size and adequate mixing, residence time and fill ratio.

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.