Occurrence of WSSV in the western hemisphere

White Spot Syndrome Virus (WSSV) is a virulent pathogen that is threatening shrimp farming industries worldwide. As of August 1999, its presence had been officially confirmed in at least seven countries in the Americas: U.S.A., Honduras, Nicaragua, Guatemala, Panama, Colombia and Ecuador. In most of these countries WSSV-positive animals have been found in both wild and farmed shrimp populations. Initial mortalities reported in these countries were generally light, but within a few months of the initial reports, mortality rates in many shrimp farms had reached high levels. The lag period between introduction of the pathogen into a naive (pathogen-free) wild population and the occurrence of heavy mortalities reflects the time required by the virus to amplify its presence in the environment, host organisms, and the culture ecosystem.

Many of these symptoms are also characteristic of other diseases, for example Taura Syndrome Virus (TSV), which make accurate diagnosis based on gross symptoms difficult. Therefore, rapid diagnostic tools are essential in order to identify the disease etiology. From many years of experience with WSSV in Asia, shrimp farmers there have demonstrated that earthen pond culture systems can be managed in ways that minimize the impact of the disease. By adopting routine biosecurity measures, combined with certain adjustments in the standard management of culture systems under production, it is possible to minimize the impact of WSSV (and other diseases) on shrimp production.

Pathways of transmission of WSSV

The most important pathways for transmission of WSSV to non-infected culture systems, in order of significance and prevalence, are:

- WSSV-infected shrimp broodstock or larvae

- Natural WSSV carriers or host organisms

- Water-borne (free) virions in the shrimp farm

- Fresh, frozen or uncooked WSSVpositive crustacean products; waste water effluent from shrimp processing plant

- Equipment, vehicles, human activities

- Predatory animals (birds, dogs)

WSSV-infected larvae and carrier/ host organisms are by far the most important vectors for disease transmission to uninfected shrimp. Farmers that stock WSSV-free larvae and effectively exclude WSSV carriers from their culture systems have a very high probability of success in controlling the disease.

Management of WSSV

There are three general management measures that can be used to control WSSV in shrimp farms. These measures must be incorporated into a specific health management plan, which must be tailored to the specific conditions of each farm. These measures are:

- Stock only WSSV-free post-larvae.

- Exclude the virus and all known and potential vectors from ponds.

- Minimize stress to the shrimp, which may trigger an outbreak of the disease. This may involve several measures, including pond and feed management, as well as boosting the shrimp’s immune defenses via incorporation of immuno-enhancers into the shrimp diets, among other technologies.

Production of WSSV-free larvae can be achieved using pathogen-free broodstock, maintaining biosecure conditions in the hatcheries, and implementing a thorough diagnostic screening program. The virus can be excluded from ponds by physical filtration and/or chemical treatment. Retrofitting farms to operate on a closed-cycle, with waterrecirculation, is another interesting option. And lastly, eliminating stress to the shrimp not only helps to avoid triggering an outbreak of WSSV disease (and other diseases, including vibriosis and TSV), but may also facilitate a viable production cycle even in the presence of a low grade WSSV infection. Proper pond preparation and water management strategies are valuable tools for WSSV prevention.

The presence of the white spot virus in a pond is a necessary, but not always sufficient cause of death from the disease. It is possible for a population of shrimp to contain a few infected individuals, and yet the prevalence of the disease may not expand. Acombination of factors within a pond will influence the outcome of a WSSV infection, and determine if the outbreak develops as an acute or chronic infection within the shrimp population. These factors are:

- Ambient pathogen load in the pond (free virions plus infected natural carriers)

- Number of potential vectors in the pond

- Prevalence of infected shrimp

- Overall shrimp health and changes in water quality or other environmental triggers that could stress the shrimp

- Density related effects on cannibalism

Initial pond filling and exclusion of WSSV carriers

One of the more important aspects in the control of WSSV is ensuring that ponds are free of active WSS viruses and carriers.

Free viral particles can be excluded from newly filled ponds by:

- Filling the pond with water from a reservoir or supply canal that has already been disinfected and cleared of active virions

- Filling the pond with untreated water, followed by application of disinfectants to the pond

- Filling the pond with water that has been cleared of all WSSV carriers through chemical treatment (see below), and waiting four to five days until all free viruses are no longer infectious

WSSV carriers can be excluded during the initial filling of new ponds by:

- Physical filtration through fine mesh screens

- Filling the pond through conventional screens, and then applying chemical compounds that kill all carrier organisms

- Filling the pond from a reservoir or supply canal that has been previously cleared of WSSV carriers.

Before applying any chemical agents, the legal status of their use in shrimp ponds should first be investigated. Regulatory agencies and seafood marketing organizations have little tolerance for the unauthorized use of chemicals and pesticides in the production of farmed shrimp. Therefore, the ideal mechanism for excluding carriers and free virions from ponds during filling would be to physically screen out all carrier organisms, including micro-crustaceans, and wait four to five days for the free virions to die out. Unfortunately, for large, open, flow-through culture systems, filtering millions of cubic meters of water daily through ultra fine (50 to 100 micron) screens in an attempt to prevent the entry of copepods and other micro-crustaceans may be impractical, uneconomical or impossible. However, regulatory issues notwithstanding, under special circumstances the responsible use of specific chemical compounds is a practical and economical strategy available to shrimp farmers for eliminating WSSV carriers.

Depending on pond size, the costbenefit of using chemicals to disinfect water and eliminate carriers should be carefully evaluated. In Asia, shrimp farmers commonly use a variety of chemicals to rid seawater of free viral particles, including formalin (20 to 40 ppm), sodium or calcium hypochlorite (a residual concentration of 20 to 30 ppm), and benzalkonium chloride (10 to 20 ppm). In designing a biosecure shrimp production system utilizing calcium hypochlorite as the primary disinfectant, Browdy and Bratvold (1998) utilized 20 ppm chlorine as the minimum residual oxidant dosage. A residual concentration of 30 ppm chlorine is approximately equivalent to a dosage of 300 to 400 kilograms per hectare of hypochlorite applied to a pond.

Many Asian shrimp farmers favor the use of biodegradable, low persistence pesticides for disinfecting their water. Chemical disinfectants are effective for eradicating WSSV vectors, but they are more expensive (cost per ha.) than pesticides, and possess the additional disadvantage of also exterminating phytoplankton and microbial productivity. Pesticides commonly used to eliminate WSSV carriers are Dipterex 95 SP or Nevugon, Sevin (carbaryl), and dichlorvos. Dipterex is the commercial trade name for an organophosphate pesticide whose active ingredient (95 percent) is trichlorfon. It is a nonpersistent, biodegradable insecticide, and is promoted as environmentally safe. According to the manufacturer, Dipterex has been approved by the U.S. F.D.A (but not for shrimp culture!), and is one of the few pesticides approved for use in aquaculture in Asia. It does not interfere with phytoplankton. Treatment of ponds for WSSV control using Dipterex during initial filling is as follows:

- Fill the pond to stocking level. Seal the inlet gate. Wait 48 hours for the eggs of potential carrier organisms to hatch.

- Mix the powdered Dipterex in water, and apply at a dosage of 0.5 to 0.7 ppm (5 to 7 kilograms per hectare in 1.0 meter deep ponds). The efficacy of Dipterex is pH dependent, and is optimized at a pH of 7.5 to 8.0. Pond water pH values over 8.0 require an increased dosage.

- Wait 7 to 10 days before stocking. During this period, free viral particles will no longer be infectious

This procedure can also be used to prepare water in a central treatment reservoir that can used for exchanging water in ponds already in production. It is very important to exercise precautions when using any pesticides. Personnel working with pesticides must wear protective clothing (boots, goggles, mask, gloves). Pesticides should not be applied in windy conditions, due to the risk of aerosol contamination of ponds stocked with shrimp. During application of any chemicals, be alert for crabs fleeing from the treated pond to untreated ponds.

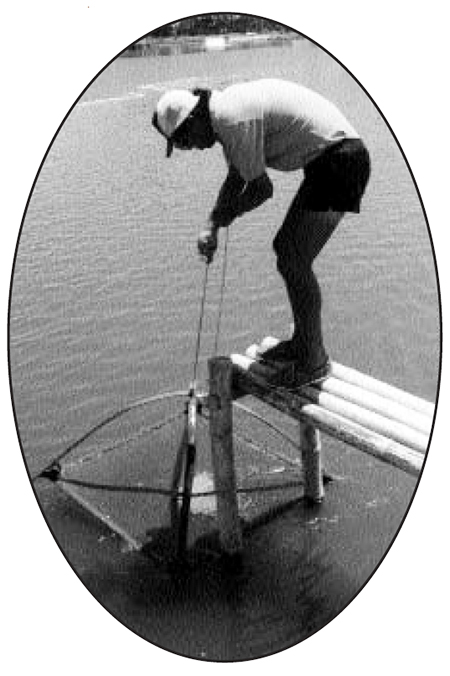

Shortly after application of the pesticide, the ponds are usually aerated heavily to accelerate the breakdown of the pesticide. Ponds without aeration should be given more time to allow degradation of the pesticide. Many pesticides are deactivated under very alkaline conditions (pH > 10), and so 500-1000 kilograms per hectare of calcium hydroxide or calcium oxide can be used to neutralize residual pesticide levels if present at the time of stocking. After pesticide or chemical disinfectant application, a plankton net can be towed through the pond of reservoir to confirm the absence of planktonic organisms. Any zooplankton collected should be checked with 2-step PCR. And two days before stocking the treated ponds, place two 48-hour survival cages with 25 to 50 PLs each at opposite extremes of the ponds to assess survival and confirm that toxic pesticide traces are not present.

It is important to note that in Asian shrimp farms that utilize pesticides to initially disinfect their seawater before filling ponds, the pesticide is not discharged from the pond and released into the environment. More-over, growers allow time for the pesticide to become neutralized or deactivated before stocking the ponds, so that shrimp do not come into direct contact with the chemical compound.

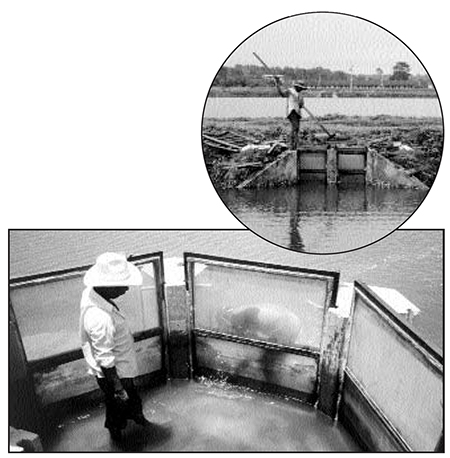

Filter screens

In the absence of chemical treatment, a large percentage of the total WSSV carriers present in the water can be selectively removed by screening the intake water. It may not be possible to eliminate all WSSV carriers from the ponds by screening; however, the more their numbers are diminished, the lower the probability of WSSV transmission to uninfected shrimp. To accomplish this goal, screens should be placed in the following strategic locations:

- Posterior to the discharge of the pumps: 2 cm mesh

- In the lateral branches of the main supply canal: 1 to 2 mm

- In the inlet structure(s) of each pond; 500 micron (secondary) screen followed by 300 micron (primary), or smaller

- In the drainage canals: 2 to 3 cm mesh

Very fine (200 to 250 micron) screens installed in the inlet structure should be used to initially fill ponds. Once ponds are filled, these filters can be replaced by 300 to 500 micron screens. Bag net filters should be used in the inlet structures to increase the effective filtering surface area, and prolong the useful time before the screen clogs. Bag net filters of 2 to 5 meters in length provide the best results, but there is no limit to the length or size of the bag net filter. Multiple bag configurations, in which one filter bag is inserted inside another, is a very effective and economical means of decreasing the mesh aperture size, without having to actually install a finer screen. Seines or gill nets (mesh size of 2-3 cm) should be installed in the drainage canals to prevent the escape of infected shrimp into the surrounding environment.

It may be necessary for shrimp farmers to rethink gate screen cleaning procedures. Typically, a person is assigned the task of cleaning the screen with a brush, while the screen is still in the water or positioned in the inlet structure. Any small crustacean carriers of active WSSV affixed to the inlet side of the screen while it is being brushed will probably be crushed, effectively releasing free virions into the pond. To avoid this, dirty screens should not be cleaned while positioned in the inlet structure, but should first be removed from the structure, and either cleaned on the dike, or immediately replaced with a clean screen.

For large farms operating under hyper-saline conditions, where low or zero water exchange strategies are not viable options, physically screening the intake water probably represents the only practical means of excluding WSSV vectors from the ponds, aside from application of chemical disinfectants. WSSV may also force shrimp farmers to re-engineer water filtration methodologies.

Many intensive shrimp farms utilize concrete supply canals, which when properly designed, can be dried between each pumping cycle. This makes possible the use of only one series of primary screens positioned at the discharge point of the pumps. In addition, mechanical micro screens (e.g. drum and sieve filters) are available that can filter out particles down to a size of approximately 10 microns.

Combining the two technologies into one water filtration system might facilitate the micro filtration of large volumes of water, thereby minimizing dependence on chemical disinfectants. Similarly, sand filters are capable of filtering out particles down to 10 microns. Using creative engineering, perhaps low maintenance, pond-side gravity filters can be designed that would screen out all WSSV vectors, including larval stages of micro-crustaceans.

Water management strategies

In areas where WSSV is present, conventional water management strategies must be modified to avoid:

- Introduction of WSSV carriers into non-affected ponds.

- Abrupt changes in water quality that could trigger increased pathogenicity.

- Release of WSSV carriers and active virions into the environment and the spread to WSSV-free farms.

Entry of WSSV carriers into ponds already in production can be avoided by eliminating water exchange, or by only exchanging water that has been cleared of WSSV carriers, either through physical screening, or chemical treatment, as discussed earlier. Eliminating or reducing water exchange is an important management tool in preventing WSSV, since it concurrently accomplishes the two goals of not allowing infiltration of WSSV carriers or free virions into the ponds, as well as avoiding drastic water changes in water quality that would stress the shrimp and trigger a WSSV outbreak. Zero or low exchange strategies are only necessary if the pathogen is already present in your shrimp farm or surrounding environment.

Low water exchange production strategies

A variety of low, or zero water exchange strategies can be used to control water quality and avoid incursion of WSSV carriers into the ponds and include:

A. Zero exchange (closed, static)

B. Low exchange (closed, recirculating)

C. Low exchange (flow-through)

D.Low exchange (partial recirculation)

E. Hybrid strategy (variable, flow through)

Strategy A, the closed, static zero exchange, refers to a completely closed, in-pond culture system in which the pond is filled with water once, and no exchange is made subsequently for the remainder of the grow-out cycle. A successful example of this strategy currently exists in Belize (McIntosh et al. 1999) in a pioneering intensive farm that has averaged productions over 11 metric tons of shrimp per hectare per crop using essentially zero water exchange (also see article by McIntosh elsewhere in this issue).

The ponds are filled initially, and no water is exchanged until harvest, when the pond water is drained into treatment ponds, and prepared for the next production cycle. The same water, after treatment, is reused for the next production cycle. The key ingredients to the success of this type of culture system are: 1) deep (1.4 meters), plastic lined ponds, 2) very heavy aeration (30 to 60 horsepower per hectare) to maintain detritus and bacterial floc in suspension, and 3) maintenance of a heterotrophic microbial feed chain that acts both as an in-pond biofilter and bio-digester of accumulated organic matter. This production system can be readily adapted for WSSV management because after each harvest, the water stored in the treatment reservoirs can be chemically treated to eradicate vectors. Some producers in Central America are already experimenting with a very simple version of the closed, static, zero exchange strategy that does not utilize pesticides (Drazba, pers. comm.).

Between each production cycle, the main supply canals are dried out to eliminate residual WSSV carriers remaining from the previous cycle. The supply canal is filled, and after waiting five days, specific blocks of ponds scheduled to be stocked that month are filled to operational level. After waiting another five days, the ponds are fertilized and stocked. Once the ponds are stocked, no water is exchanged until harvest, unless deterioration in water quality forces some water exchange.

Reportedly, 120 day production cycles with zero water exchange (except releasing rainfall accumulations) have been achieved. Low water exchange management strategies such as this implicitly require relatively low stocking densities unless aeration and/or water circulators are deployed. This is why many Asian farmers growing shrimp in intensive, aerated ponds, and employing zero or near-zero water exchange, restrict their production cycles to less than 100 days, in order to avoid pond crashes due to water quality deterioration. Zero exchange strategies are obviously not suitable to arid regions characterized by high salinities.

Strategy B is the closed, recirculating, low exchange. It is basically a batch culture system employed principally in Asia, where ponds are filled once with treated, WSSV carrier-free water, and when water exchange is required, new water is added from a central storage reservoir which has been previously treated to eliminate free virions and carrier organisms.

Water discharged from the ponds is recycled through a series of treatment ponds or reservoirs before going to a storage basin. In some farms practicing this strategy, the same water may be used for two to three production cycles before being replaced. The initial economic impact of water treatment costs in this system is lessened because the same treated water can be recycled for multiple production cycles. Water is exchanged in select ponds when water quality deteriorates.

However, in general the actual daily exchange rates using this water management strategy tend to be low. Strategy D is a variation of this system, the low exchange, partial recirculation, where some untreated water can be introduced from the external water source if the risk of WSSV is low, and water quality is acceptable. Since actual water exchange rates of ponds using these types of water management strategies are quite low, these culture systems generally require considerable aeration in order to maintain adequate dissolved oxygen, and to circulate the water.

One farm in Ecuador has incorporated ozonation into its closed recirculating low exchange strategy (B) as a means of controlling water quality and viral disease problems (Strong, 1999). The intake water is disinfected with ozone, and the treated water is recirculated throughout the farm. No untreated water is allowed to enter the ponds. Significant improvements in production have reportedly been recorded at this farm since implementing the ozonation and recirculation strategy. Ozonation also has the added benefit of being able to neutralize pesticides or other pollutants in the water. See article in “Founding Member Profile” for additional information on this system.

Non-partitioned recirculating systems have the disadvantage that a disease originating in one pond may be transmitted to other ponds. This problem can be avoided if all water in the central storage reservoir is chemically treated before release into the ponds. Nonetheless, in recirculating systems it is imperative that WSSV-infected ponds be immediately identified and isolated from the other ponds.

The low exchange flow-through water management system (Strategy C) refers to production cycles managed with constant, but very low (i.e. < 5 percent/day) water exchange, in which the intake water is filtered but untreated. This is probably the least recommended strategy, because there exists a constant risk of introducing WSSV into the ponds.

The hybrid system (Strategy E) involves zero exchange initially followed by low exchange during the final months of the production cycle using untreated water. This is a practical, low cost methodology that many shrimp farmers in the Americas will probably employ until they can adopt more biosecure water management strategies. Ponds are initially filled with water that has been chemically treated and/or filtered through fine screens to exclude most WSSV vectors. No water is exchanged during the first 4 to 8 weeks of the culture cycle. If water quality deteriorates as a result of increased shrimp biomass and feeding rates, very gradual, minimal water exchange is performed until water quality stabilizes, at which point the pond is returned to a zero exchange mode.

Judicious management of feed and phytoplankton blooms, as well deployment of aerators or water circulators, can postpone indefinitely the need to exchange water by preserving adequate water quality. Feed trays should be employed to avoid overfeeding. The fertilization program (if necessary) should be directed at encouraging stable algae populations such as chlorophytes. Producers with the necessary infrastructure (i.e. aeration) and water quality conditions can probably operate entire production cycles without water exchange, but the majority of semi-intensive shrimp farmers in the Americas may only be able to operate under zero exchange for the first 30 to 60 days, followed by small infrequent water exchanges whenever necessary.

Proper pond preparation and reduced water exchange production strategies are important tools that shrimp farmers can incorporate into their health management plans to prevent WSSV and other diseases. By adopting and strictly implementing innovative biosecurity measures, combined with certain adjustments in the standard management of culture systems under production (such as the ones mentioned here), shrimp farmers in the Americas can make significant progress towards controlling the impact of WSSV and other diseases on the shrimp farming industry.

Author’s note: Much of this article was excerpted from Clifford (in press), which is a compilation of current research and field work carried out by investigators working in countries affected by the disease, principally in Asia; individuals such as Dr. Daniel Fegan of Thailand’s BIOTEC Shrimp Biotechnology Program, and Dr. Timothy Flegel of the University of Mahidol, Bangkok.

References

Browdy, C.L. and D. Bratvold 1998. Preliminary development of a biosecure shrimp production system. In: Moss, S.M. (Editor), Proceedings of the U.S. Marine Shrimp Farming Program Biosecurity Workshop, February 14, 1998, Oceanic Institute, Hawaii. 84 p.

Clifford, H.C. In press. A Review of Diagnostic, Biosecurity and Management Measures for the Exclusion of White Spot Virus Disease from Shrimp Culture Systems in the Americas. In: T.R. Cabrera & D.E. Jory (editors). Proceedings, Second South American Aquaculture Congress. Puerto La Cruz, Venezuela, 17-20 November 1999.

McIntosh, R.P., D.P. Drennan, and B.M. Bowen. 1999. Belize Aquaculture: Development of an intensive, sustainable, environmentally friendly shrimp farm in Belize. In: Green, B.W., Clifford, H.C., M. MacNamara, and G. Montano (Editors), 5th Central American Symposium on Aquaculture, ANDAH-WAS-PDACRSP, San Pedro Sula, Honduras. p. 85-99.

Strong, C. 1999. Achieving sustainable high yields in shrimp mariculture. In: Green, B.W., Clifford, H.C., McNamara, M., and Montano, G. (Editors), 5th Central American Symposium on Aquaculture, ANDAH-WAS-PDCRSP, San Pedro Sula, Honduras, p. 223-235.

Acknowledgment

We thank the author for his article and valuable contribution.

(Editor’s Note: This article was originally published in the August/October 1999 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Henry C. Clifford III

Super Shrimp, S.A. de C.V.

Mazatlan, Mexico

Tagged With

Related Posts

Health & Welfare

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

A study demonstrated that VP19 and VP28 white spot syndrome virus envelope proteins expressed by replicon particles provided protection against mortality due to WSSV in shrimp.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 1

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors investigated the problem holistically.