Oceanic Institute documents shrimp feed processing method

The manufacture of large feed pellets by extrusion or pelleting, followed by crumbling into smaller diet sizes, is a simple and practical feed processing method for producing shrimp diets. Feed size reduction, however, can affect the physical characteristics of the diet, and, consequently, the biological performance of the animals that consume it.

Reduction in feed size must be accompanied by a proportional reduction in ingredient size, because this not only enhances nutrient uniformity in smaller diets, but also improves pellet stability and animal performance.

Feed processing and growth trial

A study was recently conducted at the Oceanic Institute in Hawaii, USA to document a shrimp feed processing method involving large feed crumbled into smaller feed particles to produce various diet sizes. The objective was to determine the effect of diet size on pellet quality and growth performance of three size classes of Pacific white shrimp (Litopenaeus vannamei).

Test feeds

In the study, a laboratory pellet mill produced 3-mm pellets, which a laboratory crumbler reduced into smaller feed particles. A sifter with six stacked sieves was used to classify the crumbled pellets into six diet sizes: 0.7-mm crumble, 1.2-mm crumble, 1.7-mm crumble, 2.2-mm crumble, 2.6-mm crumble, and 3-mm pellet. These diets were analyzed for pellet quality, and fed to shrimp during a four-week indoor growth trial using a flow-through culture system with 90 rectangular, 52-l glass aquaria.

Experimental setup

Stocking density was 12 shrimp per aquarium for 1-g shrimp, 9 shrimp per aquarium for 7-gram shrimp, and six shrimp per aquarium for 13-gram shrimp. The shrimp were fed three times daily up to satiation, and evaluated for live weight, growth rate, feed conversion ratio (FCR) and survival.

Effect on pellet quality

Proximate analysis of the six diets showed very similar composition (45 percent protein, 8.6 percent fat), indicating proper mixing of ingredients and a good manufacturing procedure. Pellet quality of the various diet sizes was evaluated for pellet water stability and pellet hardness.

Stability

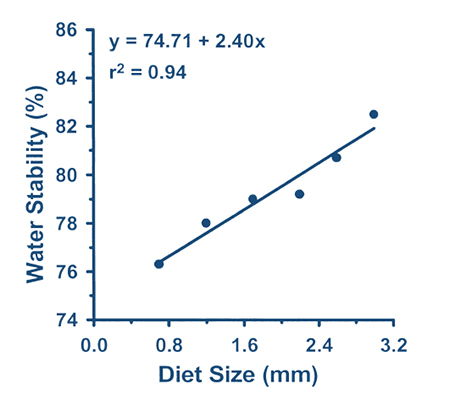

The crumbling of large pellets tends to produce smaller diets with lower water stability. Regression analysis revealed a direct correlation between diet size and pellet water stability, as illustrated in Fig. 1.

The water stability fell from 83 percent to 76 percent as the 3-mm pellets were reduced to 0.7-mm crumbles. This could be attributed to stress cracks created during crumbling, that make the resulting smaller diets more susceptible to disintegration and nutrient leaching. The surface area-to-volume ratio is also increased as larger pellets are reduced to crumbles. This could further decrease the water stability of smaller diets.

Hardness

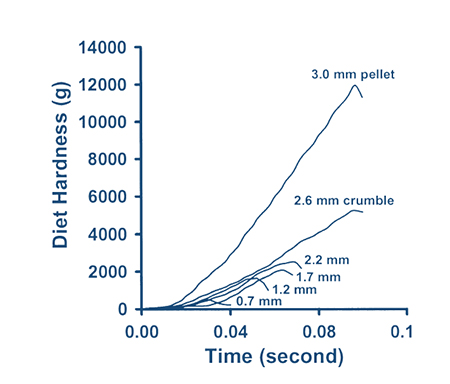

Pellet hardness of the six shrimp diets is shown in Fig. 2. Hardness is defined in this study as the force required to compress and break the pellets or crumbles to about 90 percent of their detected size, as measured with a texture analyzer. As expected, the larger pellets required more force to break them, as compared to the smaller crumbles.

In addition, hardness of diets appeared to correlate with pellet water stability. This relationship could be further explored, because of the potential for pellet hardness or pellet texture as a quick and accurate predictor of pellet water stability in shrimp feed processing.

Effect on shrimp

diet sizes.

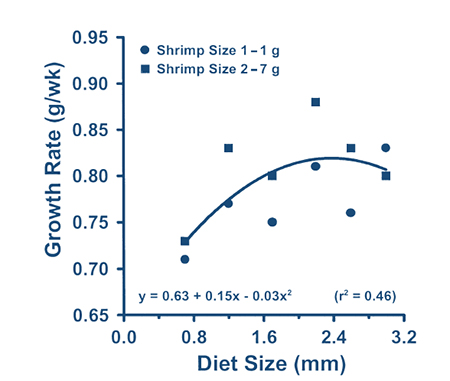

Results for shrimp growth appeared to be affected by diet size. The effects of diet size, however, were more evident in smaller shrimp. Weekly growth rates for 1-gram and 7-gram shrimp indicated significant responses to the effects of diet size, while the 13-gram shrimp showed no significant result.

The growth rates for both 1-gram and 7-gram shrimp were lowest at the smallest diet size, as shown in Fig. 3. This could be attributed to pellet water stability, which had a direct correlation with diet size. Smaller diets resulting from crumbling larger pellets would tend to have lower water stability, and consequent lower growth potential.

Growth not different

The largest diet size yielded the highest growth rate (0.83 grams per week) for 1-gram shrimp, while the 2.2-mm crumble produced the best growth rate (0.88 grams per week) for 7-gram shrimp. For 13-gram shrimp, the largest diet size also yielded the highest growth rate (1.3 grams per week). This high growth value for the large shrimp, however, was not significantly different from the growth results produced by the smaller diet sizes.

Overall, diet sizes ranging from 1.2-mm crumble to 3-mm pellet showed no significant effect on growth rate, and therefore could be utilized as diets for all three classes of shrimp. However, preference should be given to a larger pellet, due to its better water stability and higher growth performance. Results for shrimp live weights were similar to results obtained for weekly growth rates.

Conversion and survival

FCR and survival of all shrimp sizes did not show any significant response from the effects of various diet sizes. The overall mean feed conversion ratios were 1.3 for 1-gram shrimp, 2.3 for 7-gram shrimp, and 3.6 for 13-gram shrimp. These data indicate that larger shrimp were less efficient in diet utilization than smaller shrimp. Survival for all shrimp classes was about 98 percent.

Conclusion

Crumbling large feed pellets is a practical method for producing shrimp diets of various smaller sizes. However, crumbling tends to reduce the water stability of the resulting diets, and could decrease shrimp growth. An alternative approach would be to produce feeds using appropriate die sizes, and then feed shrimp with whole pellets instead of crumbles.

In this study, diet sizes ranging 1.2 to 3 mm showed no significant effect on shrimp growth. However, preference should be given to a larger pellet, due to its better stability and relatively higher shrimp growth performance. FCR and survival of the three sizes of shrimp were not affected by feed size, although larger shrimp tend to be less efficient in diet utilization than smaller shrimp.

(Editor’s Note: This article was originally published in the April 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Leonard G. Obaldo, Ph.D.

Aquatic Feeds and Nutrition Program

The Oceanic Institute

Waimanalo, Hawaii USA

Tagged With

Related Posts

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Aquafeeds

A look at India’s fish feed industry

India's fish-farming industry makes limited use of modern feeds, providing potential for the feed sector to grow. Commercial feeds are predominantly used for pangasius farming, followed by a rising popularity in carp culture.

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.