Consider quality of the equipment, costs, efficiency, reliability and serviceability

It is general knowledge that feeds for shrimp and other aquaculture species must have particle sizes small enough to meet the targeted digestibility and manufacturing characteristics. In order to determine proper particle size, it is important to consider the stage of growth and size of the target animal, and the process to be utilized to make the feed.

Nutrition and processing

From the standpoint of nutrition, the smaller the particle size, the more surface area can be accessed by digestive enzymes for better digestibility. Therefore, feed particle sizes need to be small enough to meet target species needs.

Particle size also plays an important role in post-processing. Smaller particles with more surface area cook faster when subjected to the steam in preconditioners. They also require less grinding in pelleting mills or extruders.

If particles are too large to go through the inlet of the orifice that forms pellets in a die, the rollers and die act as grinders to push them through. This can result in higher than desired energy consumption, poor pellet quality due to large pieces that can cause break points and fines, and poor water stability. Smaller, uniform particles compact better as they are extruded through the die.

A similar situation occurs with extruders because more energy is required to break down large particles. Depending on the screw configuration, some extruders do not melt at all, resulting in die blockage that reduces capacity and affects the overall quality of the product.

Particle size distribution

It is also important that the particle size distribution be as narrow as possible. In pregrinding systems where ingredients are ground separately, it is more difficult to have the final mix in a narrow range of particles. In contrast, postgrinding, in which the premixed ingredients are ground together, the particle size distribution is narrower and thus more uniform.

Particle uniformity improves processing downstream. For instance, in the pelleting process, preconditioned mash with a larger particle size distribution will have less starch gelatinization because it takes more energy and time to gelatinize large particles than small ones.

Feed durability

The best results are obtained when the mixing of feed mash is of high quality. Extruder systems usually work better when the raw materials have a particle size distribution of 95 percent after passing 250- or 177-µ screens.

Both mixing and grinding processes are critical to the finished pellet operation. Typically, the point at which additional grind size attention becomes critical is when making 1.5 mm-diameter or smaller feeds down to 0.8 mm. At this point, most mills have to use air-swept pulverizers or double grind the mix.

Extruder manufacturers use a rule of thumb that states the largest feed particles should be no larger than one-third the die size. This rule, coupled with the extruder die, determines particle size requirements, and ultimately whether a fine-grinding hammer mill or ultrafine-grinding air-swept pulverizer is required for production.

Pellet density

Shrimp feed pellets have other requirements besides nutritional needs. Pellet density plays a huge role as to whether the product will sink immediately and/or lose integrity and break apart. Finer particles tend to form a tighter bond or pack, resulting in higher density.

When each pellet or particle has more surface area per unit weight, the result is a stronger, more densely packed pellet that reduces the tendency to soak up water and break apart. Loosely packed particles that quickly break apart negatively impact pond water quality.

Pregrind operation

Prior to finish grinding, a process called pregrinding is typically carried out. This usually involves a full-circle hammer mill to individually grind whole grains such as wheat, rice, and corn. Typically, this is done using screen sizes of 3.0 to 3.5 mm). Following this process, all the major ingredients are weighed and transferred to the mixer.

After the major ingredients are mixed, microingredients such as vitamins are added for an additional mixing cycle. Once completely mixed, the ration is prepared for fine or ultrafine grinding, depending on the customer’s desired particle size requirements.

Grinding equipment

Several factors must be considered to choose the right equipment. Formulas high in protein and fat, yet lower in fiber, work very well on air-swept pulverizers, while diets high in fiber and lower in protein and oil perform well on fine-grind hammer mills. Both machines require air assist. In most practical applications, ambient air is the simplest and most affordable coolant available.

Dilute phase pneumatic conveying serves two main purposes. It carries the ground product from the grinder to the product collector and cools the material ration is prepared for fine or ultrafine grinding, depending on the customer’s desired particle size requirements.

Grinding equipment

Several factors must be considered to choose the right equipment. Formulas high in protein and fat, yet lower in fiber, work very well on air-swept pulverizers, while diets high in fiber and lower in protein and oil perform well on fine-grind hammer mills. Both machines require air assist. In most practical applications, ambient air is the simplest and most affordable coolant available.

Dilute phase pneumatic conveying serves two main purposes. It carries the ground product from the grinder to the product collector and cools the material inside the unit-grinding chamber using ambient air. This method is mainly used for air-swept pulverizers prior to pelleting or extruding aqua feeds smaller than 2.5 mm. It is also used on fine-grind hammer mills with variations of this arrangement. For either unit, the air/cooling system is critical to system operation.

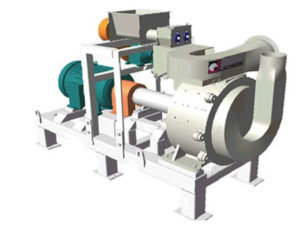

Pulverizers do not have screens like hammer mills, also known as high-speed impact mills. They operate with material metered into the air stream at the inlet. The material is impacted by carbide-tipped hammers connected to beater plates to reduce large particles and distribute the material around the interior of the grinding chamber. The tip speeds of the beater tips can reach 31,000 fee per minute, thus producing fine grinds. As impacts continue against the corrugated liner ridges, particles are further reduced and the ground material is pulled into the product collector.

Air-swept pulverizers have lower capacity than fine-grind hammer mills. However, they are capable of producing fine grinds of 95 percent minus 250 µ at rates of 10 to 15 kilograms per horsepower per hour.

Hammer mills

Like air-swept pulverizers, fine-grind hammer mills also impact the metered ingredients mixed with the air stream. Material is impacted with hardened, hard-faced hammers and thrown against cutting plates for the initial particle break. The material bounces off the cutting plates and is impacted by the swing hammers again. The material then approaches the screen at the interior velocity of the grinding chamber at an acute angle, thus providing further size reduction.

Fine-grind hammer mills can grind product to 90 to 95 percent minus 420 µ. Their performance depends on the fat, fiber, and protein content of the formula. Hammer mills tend to work well on fiber-type diets and not as well when high fat is present, due to screen-blinding issues.

Supplier selection

There are many factors to consider when selecting an equipment supplier for processing feeds. Consideration should be given to the quality of the equipment, initial investment cost, efficiency and operating costs, reliability and serviceability. Ask for lab testing to verify particle size distribution and capacity on one or more formulas. An experienced, reliable supplier that supports its equipment installations is a valuable partner.

(Editor’s Note: This article was originally published in the October 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Eugenio Bortone, Ph.D., PAS, Dpl. ACAN

1521 Country Club Drive

Red Bay, Alabama 35582 USA

Tagged With

Related Posts

Aquafeeds

Shrimp feeds depend on proper ingredient grinding

The proper feed particle sizes of aquafeed ingredients are established by the nutritional requirements of the species targeted and by the feed manufacturing process used. For proper ingredient particle sizes, various characteristics are very important, including particle size distribution and pellet density.

Aquafeeds

Aquaculture Exchange: Andrew Jackson, IFFO

Aquaculture remains dependent on fishmeal and fish oil, crucial marine ingredients in aquafeeds, particularly at key life stages. Andrew Jackson, technical director at IFFO and one of the world’s foremost fishmeal experts, tells the Advocate that the two industries can coexist well into the future if properly managed.

Aquafeeds

Best practices for optimum shrimp feeds

Producing a consistent shrimp feed pellet requires that all ingredients are processed properly and monitored through proper in-line quality assurance.

Health & Welfare

Extruder design changes increase production capacity for small-diameter feeds

The authors designed changes for single- and twin-screw extruders that streamlined the extrusion process to achieve higher output rates for small-diameter aquafeeds.