Sanitizer for aquaculture water treatment is an option for organic aquaculture operation

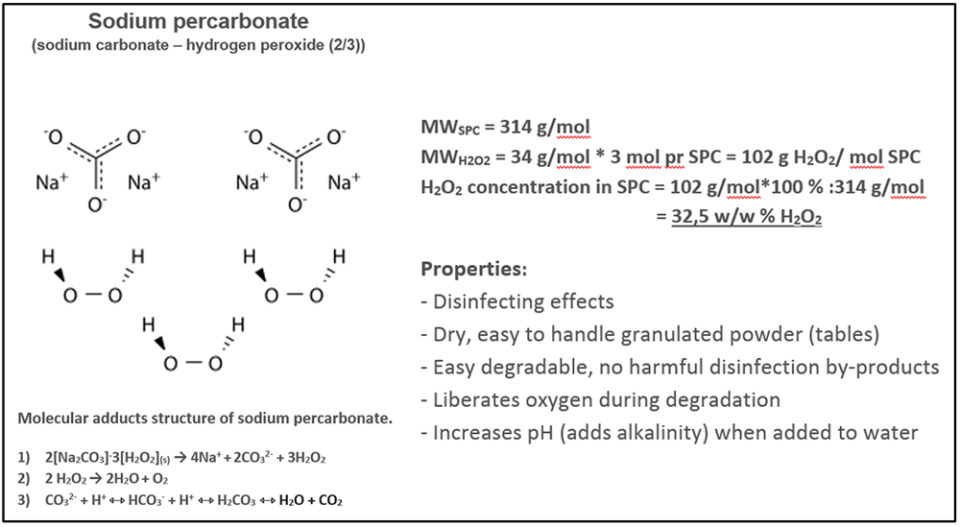

Water treatment options for organic aquaculture are restricted, compared to those available to conventional fish farming; only easily degradable disinfectants are allowed. One of the permissible water disinfectants that can be used in both conventional and organic aquaculture production systems is sodium percarbonate (SPC). SPC is a dry, granulated form of hydrogen peroxide (H202), being a crystalline adduct of H2O2 with sodium carbonate (2Na2CO3·3H2O2; Fig. 1).

SPC decomposes in water into Na+, CO32- and H2O2. It has different trade names – Oxyper, Biocare or Oxypro – and is also referred to as “emergency oxygen powder.” The product has documented anti-parasitic effects (Heinecke and Buchmann, Aquaculture 288.1 (2009): 32-35), controls unwanted algae growth and has sanitizing properties, and liberates oxygen during its decomposition.

The advantage of applying SPC over other H2O2 products is that it is safe and easy to handle. Being a granulated powder, it can be evenly distributed in a pond or raceway by use of a hand shovel, as shown in the picture above.

The added powder can be visually checked as it precipitates to the bottom of the tank or raceway when added to the water, helping guide and ensure a safer, more even and effective distribution. Immediately after the addition of SPC to the water, hydrogen peroxide reacts with organic matter and bacteria in the sediment.

During the enzymatic breakdown of H2O2, oxygen is formed, which is seen as microbubbles emerging from the bottom/sediment. This process may help in liberating organic matter and debris from the bottom, which is another apparent, beneficial property of this product. The water quality is momentarily deteriorated as a result of this, and some decomposition products (flocculated material, particulate organic matter) may accumulate on the surface following the water treatment procedure.

Example of SPC application on a commercial fish farm

SPC can be used to improve water quality by the indirect addition of oxygen and associated elimination of bacteria. As a side effect, it purifies the bottom in concrete raceways in hatcheries, and cleans up the sediment in earthen ponds when SPC reacts with the organic matter. The dosages vary from system to system and depend on factors like fish size, water temperature and water quality (organic matter content).

In January 2017, we measured the associated effect of adding SPC to a 100 m3 earthen pond with juvenile (150 to 200-gram) rainbow trout. An amount of 12 kg SPC was evenly added using a hand shovel to the pond over a period under five minutes.

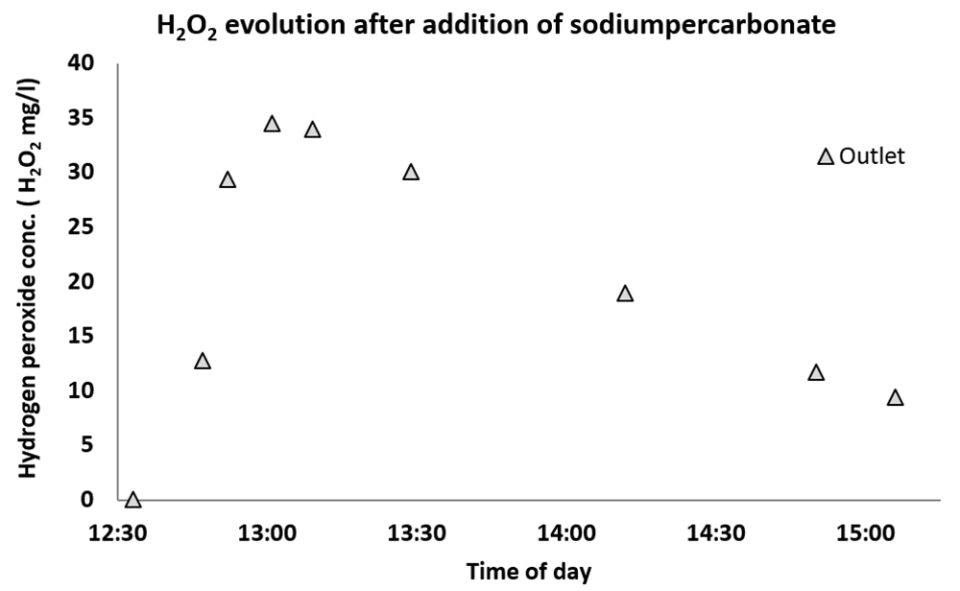

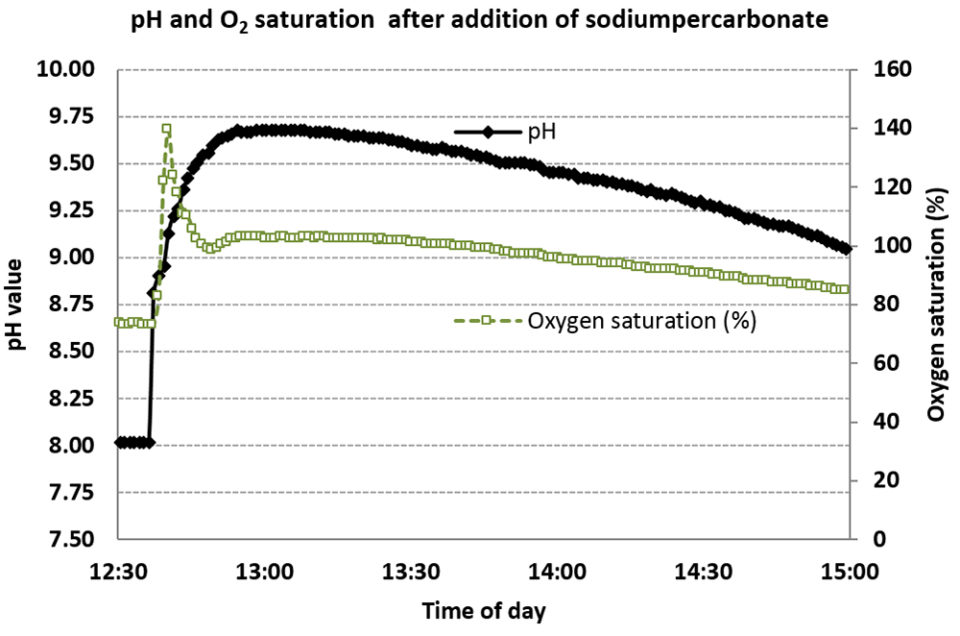

At the outlet of the pond, oxygen and pH sensors were installed to record and log data prior to, and during SPC application. Water samples were collected in transects across the pond and from the outlet of the pond to assess hydrogen peroxide concentrations. H2O2 concentrations were estimated by use of commercial Peroxid sticks (0-25 ppm H2O2) and analyzed in the field with a portable spectrophotometer and a fixating color reagent.

The concentration of H2O2 peaked at 35 ppm at 30 min after the SPC was added to the pond (Fig. 2). The concentration remained above 10 ppm for over two hours, declining as a result of dilution and degradation within the pond. The associated effects of SPC addition and thereby release of alkaline carbonate ions was seen as a markedly increases in pH from 8.0 to > 9.5 within 10 min. Oxygen concentration increased from approx. 75 percent saturation to 140 percent saturation just after SPC addition. The oxygen concentration decreased but remained at an elevated level (> 90 percent saturation) for two hours.

Perspectives

The above example of a simple water treatment practice from a commercial organic fish farm shows that it is easy to apply, but also that precautions should be taken. The concentration of H2O2 and the contact time obtained can efficiently control fish parasites and improve the water quality without negatively affecting the fish. However, the release of carbonate ions and their impact on pH may result in critically elevated pH levels, in this case transiently above pH 9.5. Long-term elevated pH values above the tolerance area of the fish challenges their physiological equilibrium or homeostasis, making the fish less resistant.

Furthermore, significant pH increase will affect the ammonium-ammonia equilibrium (NH4+ H2O ⇿ NH3 + H+) forming a larger fraction of the toxic free ammonia (NH3), which is detrimental to most reared fish species even at very low concentrations. Therefore, when implementing a new sanitizer as part of the management practice, it is always recommended to begin with low dosages and then gradually increase them until the desired concentrations is reached, and always considering the response of the fish before, during and after water treatment episodes.

The beneficial side effects in addition to disinfection, increased oxygen supply and organic matter release from the sediment, should be considered to be a short-term alternative to more sustainable habits, for example the maintenance of stable oxygen levels and manual cleaning of the ponds.

The authors appreciate the collaboration with Thim and Flemming Skov, fish managers at the organic fish farm. The study was funded by RobustFish; part of the Organic RDD 2 program, which is coordinated by International Centre for Research in Organic Food Systems (ICROFS). It has received grants from the Green Growth and Development programme (GUDP) under the Danish Ministry of Food, Agriculture and Fisheries.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Lars-Flemming Pedersen, Ph.D.

Senior Research Scientist, Section for Aquaculture

DTU Aqua

National Institute of Aquatic Resources

North Sea Science Park, P.O. Box 101

9850 Hirtshals, Denmark

-

Alfred Jokumsen, M.Sc.

Senior Advisory Scientist, Section for Aquaculture

DTU Aqua

National Institute of Aquatic Resources

North Sea Science Park, P.O. Box 101

9850 Hirtshals, Denmark

Tagged With

Related Posts

Health & Welfare

In sea lice fight, salmon farmers phasing out hydrogen peroxide

An over-reliance on medical and chemical controls, along with warming waters, led to a surge in sea lice. With such treatments waning in effectiveness, operators turn to other, safer measures.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Health & Welfare

Linking water treatment practices and fish welfare

Quantification of fish behavior is complex and depends on the experimental setup and biomarkers applied. A simple method was tested to quantify locomotor behavior to evaluate the effects of simulated water treatment scenarios using peracetic acid.

Health & Welfare

Emerging epitheliocystis disease in Mediterranean sparids caused by novel bacteria

Epitheliocystis is an emerging infection among farmed gilthead seabream and is also lethal in mesocosm cultures of sharpsnout seabream larvae. Two studies of this disease at sites in Greece and Crete have characterized the gill and skin cysts in more detail.