QIM approach can assure uniform evaluation, fewer misunderstandings

Is this fish fresh? How long will it stay that way? These are the questions every buyer asks when shopping for fish, whether for the dinner table or the production line. They can be difficult to answer objectively. In everyday practice, inspectors evaluate smell and visual appearance using the most standardized criteria possible. But those are only two of several elements that indicate the varying quality of fish.

Quality index method

The Quality Index Method (QIM) is a systematic, objective guideline that simplifies the quality-assessment process. QIM originated from Tasmania, but most QIM schemes have been developed in Europe, where the method is widely applied.

The QIM approach can be used by all links in the seafood supply chain – farmers, distributors, buyers, and consumers – assuring more uniform evaluation and fewer misunderstandings. QIMs are easier to use than some sensory methods and do not require any equipment other than the human senses. All quality descriptors are well defined, and most of the schemes include thorough instructions with illustrations. As a result, limited training is needed to achieve accurate results.

QIM principles

All fish species have their own spoilage patterns and indicators. Some spoil quickly, while others have a comparatively long shelf life. Some species develop offensive odors and tastes, while others show little of these telltale signs as quality declines. For many of the sensory methods currently used, inspectors must adjust broad methods to suit particular species. QIMs, however, make the evaluation of freshness faster and more precise, as the sensory criteria are tailored to each species.

QIMs are available for a large range of fish and crustacean species, both wild and farmed. The methods are all based upon the same principles, but the parameters used depend on the changes that occur in different fish species during storage and spoilage. The assessor must evaluate all the defined parameters, which usually include the appearance of skin, eyes, and gills, as well as odor and texture. This makes the parameters more equal in importance, and therefore limits subjective evaluations.

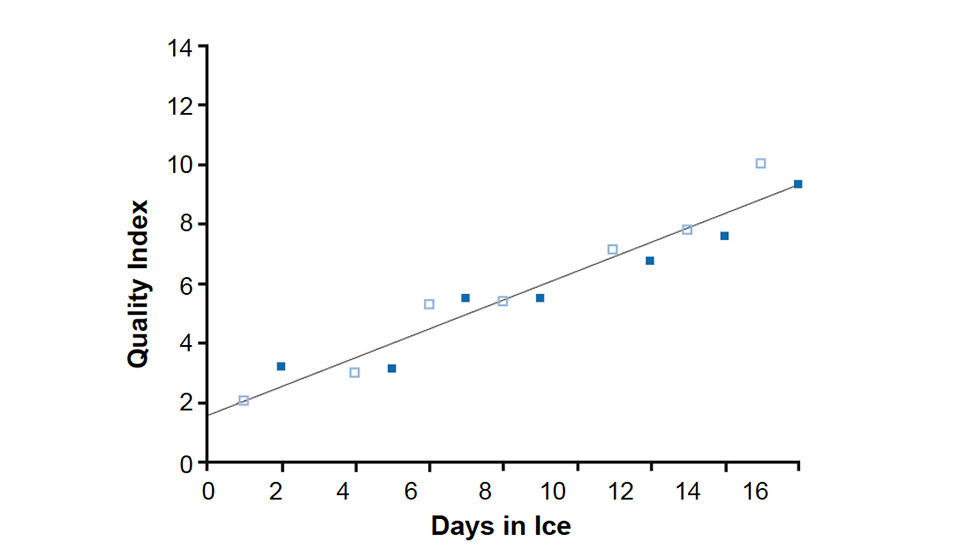

Each parameter carries a demerit score that normally ranges zero to 3. The scores for all the characteristics are summarized in an overall sensory score, the quality index, which increases as quality decreases. Very fresh fish have a score near zero. The higher the score, the shorter the time the fish can still be sold as a high-quality product. Quality indexes increase linearly with storage time in ice, so the evaluation results can be used to estimate the remaining shelf life of the fish.

U.S. QIM initiative

The Seafood Laboratory of North Carolina State University’s Food Science Department has developed a QIM for farmed hybrid striped bass in one of the first QIM research projects in the United States. These fish were chosen because they are an increasingly popular farmed species in the southern United States.

The QIM was developed using two trained sensory panels. One panel evaluated the whole raw fish according to the QIM principles. Samples were then cut from the fish, cooked, and served to another panel that evaluated the appearance, odor, flavor, and texture of the cooked samples. The shelf life was estimated from evaluations of the cooked samples.

Nielsen, Quality parameters included in the North Carolina State University QIM, Table 1

| Quality Parameters | Points | |

|---|---|---|

| Whole fish | Skin color/appearance | 0-1 |

| Whole fish | Odor | 0-2 |

| Whole fish | Texture | 0-2 |

| Eyes | Clarity | 0-2 |

| Eyes | Shape of pupil | 0-2 |

| Gills | Appearance of mucus | 0-1 |

| Gills | Color | 0-2 |

| Gills | Odor | 0-2 |

| Total points = Quality Index | 0-14 |

By comparing the results from both panels, a QIM (Table 1) was formulated that showed a strong linear relationship between the quality index and storage time (Fig. 1). The QIM can estimate the shelf life of farmed hybrid striped bass with an accuracy of approximately one day. This scheme also quantifies specific quality defects, such as poor eye clarity. It can therefore be used as a tool by farmers to optimize product quality – and prices.

Comparative value

The two farms that participated in the QIM development handled fish differently before harvesting. One farmer harvested directly from the pond. The other included a purging step in which residual feed was removed from the stomachs of the fish by placing the fish in a tank with clear fresh water. The differences in quality due to these procedures could be quantified with the QIM.

It was found that hybrids harvested directly from the pond more frequently had muddy or earthy odors than the purged fish. Keeping the hybrids in the purging tank also changed the appearance of their skins. The desirable dark stripes that are a trademark for the hybrid striped bass industry became more distinct. This, as well as the red bruising in the belly area of the bass that occurs from time to time, was also easily quantified with the QIM.

Fish farmers can use such data to get a better picture of how different practices influence the quality of their products and adjust their procedures accordingly. Using the QIM scores, they can sort crops more precisely into quality categories and market them to the most appropriate customer segments.

Other applications

Detailed quality descriptions can be utilized by several links in the chain between the farmer and final buyer. Processors can use QIMs to estimate shelf life and plan production more efficiently. For electronic auctions, where buyers purchase fish sight unseen, QIMs have an obvious advantage over other sensory methods. Quality indexes can also play an important role in traceability, because such data can be applied through the entire chain to check accuracy.

Further use

In Europe, QIMs have been widely accepted by both industry and research institutions. QIM schemes have been developed in cooperation with the fishing and farming industries. Work is being conducted to adopt QIMs at large fish auctions, and more general QIMs are being adapted for consumer use. When expanded for other farmed species, QIMs could also become integral parts of the aquaculture industries in the United States and other regions.

(Editor’s Note: This article was originally published in the August 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Durita Nielsen, Ph.D.

Research Scientist

North Carolina State University Department of Food Science Seafood Laboratory

Center for Marine Sciences and Technology

303 College Circle

Morehead City, North Carolina 28557 USA[117,100,101,46,117,115,99,110,64,101,115,108,101,105,110,100]

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Health & Welfare

Artificial upwelling maintains favorable summer environment for farmed oysters

The summer season poses threats for oyster aquaculture worldwide. In addition to high mortality, poor oyster quality and health – especially in enclosed bays – are often attributed to water stratification, high temperatures and hypoxia.

Responsibility

Constantly changing pH unavoidable, completely normal

Prof. Claude Boyd discusses the importance of pH for farmed fish and shellfish, the normal and natural fluctuations and how aquaculture systems can manage it.

Health & Welfare

Continuous improvement from farm trials

Continuous improvement is a critical strategy required for the success of any business, including shrimp farming. Routine programs for farm feed trials that incorporate best practices can contribute to better decision making and a faster improvement.