Survival rate for each species was high, with no evidence of disease

High-density culture of channel catfish in tanks or raceways has several advantages over traditional pond culture, including the elimination of trash fish, less food loss, easier harvesting, elimination of taste and odor problems, and no exposure to pesticide contamination. Closed indoor systems conserve water and heat, allowing aquaculture production in arid or water-restricted areas and throughout the year, reducing discharges, and minimizing environmental impacts. With the greater control afforded by these recirculating aquaculture systems (RAS), organic certification can be more easily attained and maintained. Product taste and nutritive qualities can also be improved through finishing diets and purging.

Few studies of channel catfish growth polycultured with tilapia have been conducted in RAS. Nile tilapia polycultured in cages have stimulated catfish growth, presumably by stimulating feeding responses. Blue tilapia in high-density raceways have reduced catfish growth through feed competition. However, in the presence of tilapia, enteric septicemia or hole-in-head disease, the most serious of the catfish diseases, was absent.

RAS study

The authors evaluated the combined growth of mixed-sex Nile tilapia and channel catfish in an RAS and the resulting fatty acid profiles in their fillets due to the added fishmeal and fish oil in the trout chow diet used to feed the fish.

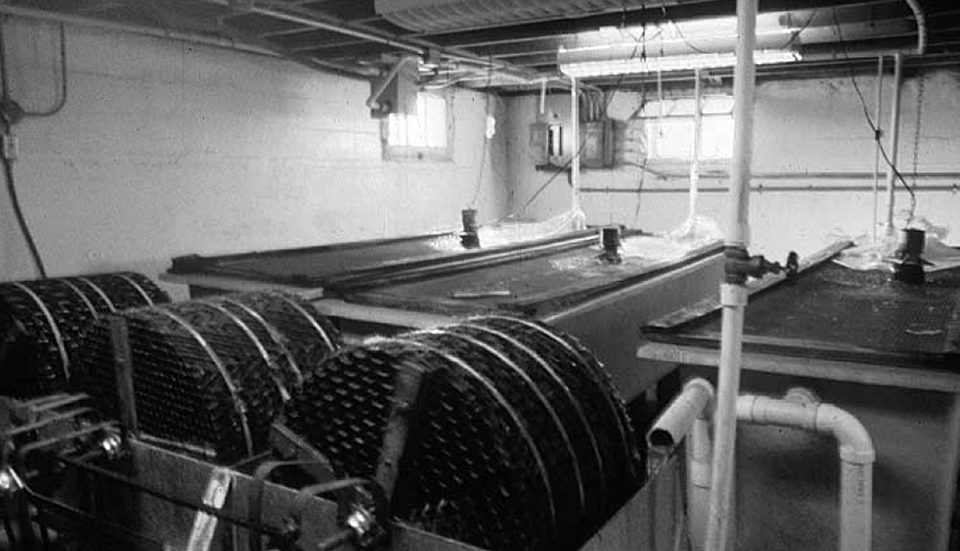

The experimental system consisted of a 2.4-cubic-meter rearing tank and 1.7-cubic-meter settling tank with two 0.13-cubic-meter rotating biological contactor biofilters. The surface area of the filters was 78 square meters of commercial biofiltration material configured as vertical plastic sheets of structured packing cells. Water was circulated at 52 liters per minute, with 2.2 percent replacement per day. Water temperature was maintained at approximately 29 degrees-C. Sodium bicarbonate was added when pH dropped below 7.0.

In September, 260, 22-gram Nile tilapia were stocked at 63 per cubic meter and fed to satiation daily with trout chow crumbles. By April 1, their average weight was 358 grams and growth averaged 1.7 grams per day. At that time 100, 361-gram channel catfish were stocked in the same rearing tank at a density of 25 catfish per cubic meter. This lower stocking was to prevent dominance by catfish. The fish were fed 40 percent-protein commercial trout chow daily in one or two feedings and up to 2.7 kilograms per day based on water quality.

On June 10, after 71 days, a power failure prompted harvest of the system. To evaluate flesh quality, proximate and lipid profiles were determined by a commercial laboratory using fillets from two catfish and two tilapia.

Results

Survival was 96 percent for each species, and no evidence of any diseases was noted. At the end of the study period, tilapia averaged 484 grams and their daily growth was 1.8 grams per day, while channel catfish averaged 608 grams with daily growth of 3.5 grams. Only small numbers of tilapia seedstock were harvested, although schools of small tilapia were noted in the tank. Catfish predation on these was probably substantial. The aggregate tank loading was 38.9 kilograms per cubic meter and 1.5 kilograms per square meter of filter area. The aggregate food conversion was 1.46.

Water quality was variable. Nitrite ranged 0.5 to 14 milligrams per liter, total ammonia nitrogen was measured at 0.06 to 6.5 kilograms per liter, pH was 6.6-8.0, and dissolved oxygen levels ranged 3 to 7 kilograms per liter. The tilapia appeared to have reduced feeding at nitrite levels above 5 kilograms per liter. Water temperature varied 26 to 31 degrees-C during the test.

The fat levels of the catfish and tilapia fillets were similar at 8.6 and 6.5 percent, respectively. Of the total fat levels, saturated fats made up 29 percent in catfish and 35 percent in tilapia. Monounsaturated fats reflected 51 and 42 percent, while polyunsaturated fats took up 16 and 15 percent, respectively, of the total fats measured.

Desirable omega-3 highly unsaturated fatty acids comprised 7.0 percent in catfish and 3.8 percent in tilpia. Docosahexaenoic acid values were 3.7 and 3.2 percent, respectively, in the catfish and tilapia, with eicosapentaenoic acid at 1.4 and 0.3 percent. The omega-6:omega-3 ratios were very favorable at 2.2 and 2.5.

One concern was the presence of off-flavor. The tilapia were noticeably affected by geosmin. A window adjacent to the tank may have allowed the proliferation of geosmin-producing microorganisms, which the tilapia may have ingested.

Companion study

In a companion study with a similar 3.9-cubic-meter system, flow rate of 38 liters per minute, and channel catfish fed trout chow at 3 percent body weight per day, stocking was approximately doubled (150 per cubic meter) and final loading was 61 kilograms per cubic meter, with a feed conversion of 1.1. Growth dropped to 2.9 grams per day and survival was 86.7 percent. No off-flavor was noted.

The system was located in a basement with little outside light. Without tilapia, a disease outbreak occurred. The trout chow also produced a marked improvement in the nutritive value of the fish.

Conclusion

With catfish and Nile tilapia raised in experimental RAS polyculture, good catfish growth rates approximating those found in polycultured cage culture were observed. Tilapia growth rates were approximately half of results obtained in polycultured cages. The tilapia may have utilized lipids poorly for energy and growth.

The aggregated costs per kg gain of catfish and tilapia were U.S. $1.10 for electricity and $0.66 for feed. Both could be reduced with further work.

(Editor’s Note: This article was originally published in the April 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Peter Perschbacher, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

Box 4912

Pine Bluff, Arkansas 71610 USA[117,100,101,46,120,101,97,117,64,114,101,104,99,97,98,104,99,115,114,101,112,112]

-

Donald Freeman, Ph.D.

USDA, Agricultural Research Service

H.K. Dupree Stuttgart National Aquaculture Research Center

Stuttgart, Arkansas, USA

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Health & Welfare

‘Boutique’ RAS for spotted sea trout

A boutique design project validated a land-based, recirculating production system capable of producing 50 metric tons of spotted sea trout per year.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.