Restrictions are imposed on animal byproducts in feeds

Fishmeal has traditionally been the preferred source of protein in many aquaculture feeds. But for several years, there has been increasing interest in identifying alternatives to fishmeal, mainly because of its generally high price and variable availability.

Suitable alternatives

To be suitable as fishmeal replacements, ingredients need to be cost-effective, which generally means they need to be cheaper than fishmeal. They must be nutritious (i.e., a source of well-balanced and available amino acids), available in significant quantities, of consistent quality, palatable to the targeted aquatic animal, capable of being included in a feed. In addition, they must also not contain antinutritional factors.

Many of the alternate sources of protein used in aquaculture are made from plants like soybeans, wheat, corn, and canola, primarily because of their attractive costs. These plant-based products are limited in their scope in the feeds of some aquatic animals because of lower palatability, imbalanced amino acid profiles, and the frequent presence of antinutritional factors.

Animal byproducts

Although heavily regulated in some parts of the world, ingredients made from animal byproducts meet many of the criteria above, and have excellent prospects as alternative ingredients for aquaculture feeds. Included in this category are byproducts of the livestock industry, such as meat and bone meals.

Meat and bone meal evaluation

Under a project funded by Fats and Protein Research Foundation, Inc. of Bloomington, Illinois, USA and the USDA ARS, the authors recently evaluated the potential of three commercially sourced meat and bone meals as replacements for fishmeal in feeds for Pacific white shrimp (Litopenaeus vannamei). These ingredients were made of various combinations of rendered beef, poultry, and swine by-products (Table 1). The three ingredients varied little in protein content (53.3 to 55.6 percent as fed), but greatly in fat (10.6 to 17.1 percent) and ash (19.0 to 24.1 percent).

Forster, Composition of three meat and bone meals, Table 1

| Source | Meal 1 | Meal 2 | Meal 3 |

|---|

Source | Meal 1 | Meal 2 | Meal 3 |

|---|---|---|---|

| Beef | 35% | 90% | 50% |

| Pork | 35% | 5% | 50% |

| Poultry | 30% | 5% | – |

Digestibility trial

An in vivo digestibility trial was conducted using the indigestible (chromic oxide) marker technique, a conventional indirect approach. In this method, the digestibility of a standard reference diet is compared with a diet containing the standard reference diet in combination with a known quantity of the test ingredient.

The results of this trial indicated variability in the digestibility coefficients of protein among the meat and bone meals (81.0-87.8 percent), with values generally lower than that of the fishmeal-based control diet (92.6 percent). The amino acid apparent digestibility, not surprisingly, closely followed the pattern of the overall protein.

Growth trial

In a growth trial, researchers manufactured 10 pelleted diets: a fishmeal-based control diet with no meat or bone meal, and nine experimental diets that contained each of the meat and bone meals in replacement of 25, 50 and 75 percent of the fishmeal. These diets were equalized for protein and fat.

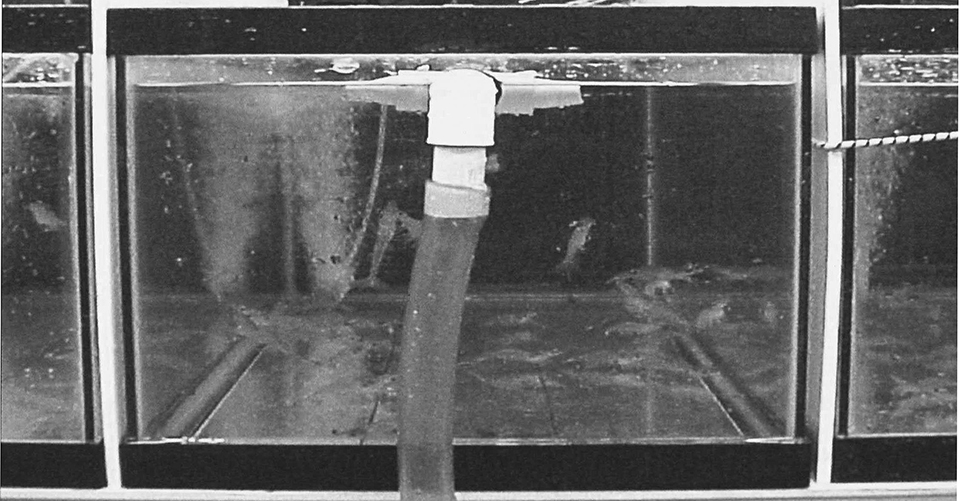

Pellet stability analysis revealed that the diets with higher levels of meat and bone meals held together longer in water than the control diet, indicating the meals had favorable binding characteristics. Three tanks of juvenile shrimp were fed the diets for eight weeks, after which the growth of the animals was used to assess the meat and bone meals.

Survival of 82 to 90 percent in the animals was not variable among the dietary treatments. All the experimental meals were able to replace 25 percent of the fishmeal with no loss of growth. However, at levels of 50 and 75 percent fishmeal replacement, there was a general reduction in shrimp growth, especially in two of the meals. In the diets containing the third meal, however, growth reduction was slight, even at 75 percent fishmeal replacement.

The ranking of the meat and bone meals by apparent digestibility coefficients was different than by growth promotion, indicating that digestibility was not a key variable in these ingredient sources. Interestingly, the best performance was found in the meal with, at 90 percent, the highest content of rendered beef byproduct.

BSE concern

The use of animal byproducts in animal feeds has become a sensitive issue in recent years because of concern over the spread of Bovine Spongiform Encephalopathy. As a result, restrictions have been imposed on animal byproducts in animal feeds. In North America, the use of meat and bone meals in feeds for ruminant animals is prohibited by the United States Food and Drug Administration. In countries such as the United Kingdom, a ban against the meals applies to all animal feeds.

Conclusion

This research clearly indicated that meat and bone meals can be a suitable ingredient for inclusion in shrimp feeds, but the considerable variation in composition among commercial products can affect nutritional quality. The rendering industry may find it profitable to initiate quality control as a promotional tool to increase the use of these ingredient in feeds for aquatic animals.

(Editor’s Note: This article was originally published in the April 2003 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Ian Forster, Ph.D.

The Oceanic Institute

41-202 Kalanianaole Highway

Waimanalo, Hawaii 96795 USA -

Warren Dominy, Ph.D.

The Oceanic Institute

41-202 Kalanianaole Highway

Waimanalo, Hawaii 96795 USA -

S. Divakaran, Ph.D.

The Oceanic Institute

41-202 Kalanianaole Highway

Waimanalo, Hawaii 96795 USA -

Leonard Obaldo, Ph.D.

The Oceanic Institute

41-202 Kalanianaole Highway

Waimanalo, Hawaii 96795 USA -

Albert G.J. Tacon, Ph.D.

Aquatic Farms Ltd.

Kaneohe, Hawaii, USA

Related Posts

Aquafeeds

Animal protein meals reduce feed costs but don’t improve shrimp performance

The authors conducted a study to determine how replacement of salmon meal with various animal protein meals in feed affected the growth performance of white shrimp.

Health & Welfare

Effects of poultry protein concentrate, phosphorus supplementation in barramundi juveniles

This study characterized the nutritional value of a high-quality poultry protein concentrate against standard poultry meal in barramundi juveniles.

Health & Welfare

Fishmeal replacements: Rendered protein meals effective

Research indicates that rendered protein meals could replace significant amounts of fishmeal in diets for shrimp and several cultured fish species without reducing weight gain.

Aquafeeds

Gamma irradiation enhances nutritional value of animal byproducts

Gamma irradiation treatment presents a possible processing technique for reducing anti-nutrients and improving the nutritive quality of many feed ingredients.