Few samples correctly report the amount of sodium in the nutrition facts panel

For centuries, salt has played an important role in the preservation and flavor enhancement of many food products, including all seafood. The ions that form salt, or sodium chloride, are an essential part of the human diet, regulating water balance and maintaining fluid volume in the liquids surrounding cells. Nevertheless, diets high in sodium are known to increase blood pressure, which can lead to heart disease and stroke, two leading causes of death.

Although media coverage and physicians have made consumers aware of the health implications of diets high in sodium, and the food industry has invested billions of dollars on required labeling for nutrition facts that recommend consumers not have over 2,400 mg sodium per day, the American Heart Association reported earlier this year that the average American still consumes 6,000-18,000 mg sodium daily.

Regulatory agencies, health care professionals and consumer groups in the U.S. are concerned with this fact. The Food and Drug Administration (FDA) may change the regulatory status of salt and sodium, and establish additional food-labeling requirements for levels of sodium in the final product. The daily recommended intake value of sodium is also being revised.

Likewise, European legislators have encouraged the food industry to reduce the sodium content of all foods since 2006. Although United Kingdom consumers’ daily salt consumption has fallen from 3,800 to 3,440 mg sodium, the U.K. Food Standards Agency is is contemplating to make the voluntary industry salt reduction program stricter in order to reduce salt intake to 6,000 mg per day.

Sodium in shrimp

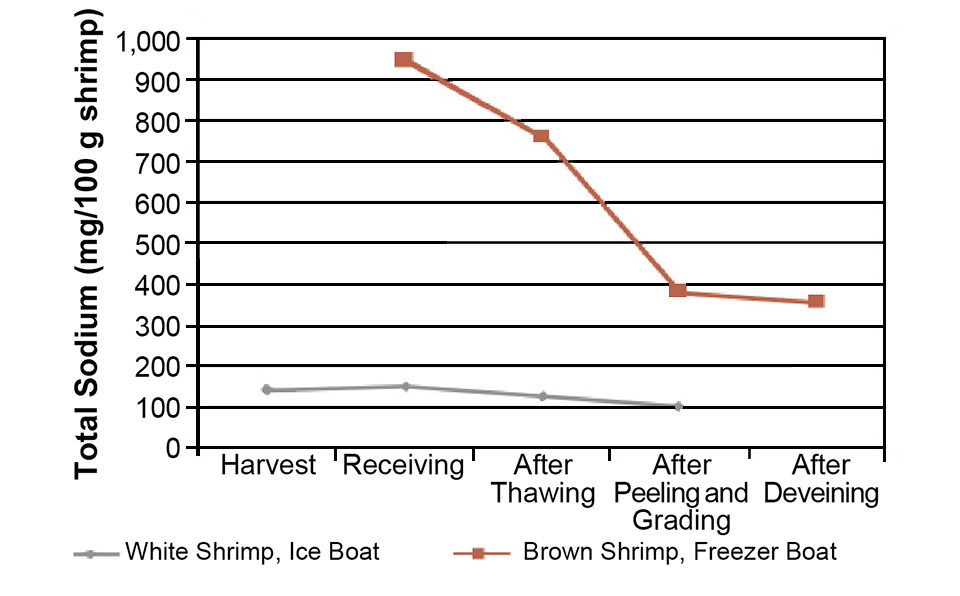

Sodium is a natural component of all seafood. Shrimp, for example, when harvested can have 250 to 300 mg sodium per 100 grams of meat. When shrimp are stored in ice slush in accordance with good manufacturing practices, the level of sodium begins to decrease due to two factors: an increase in moisture in the product and leaching of sodium into the ice slush. If the product is frozen in salt brine prior to processing, the sodium levels in the edible meat can temporarily increase but eventually decrease when the product is thawed and further processed (Fig. 1).

Another source of sodium in shrimp can be the use of salt and/or moisture-retention agents (MRAs) during processing. Since the 1960s, phosphates – a group of additives generally recognized as safe (GRAS) – have been the moisture-retention agent of choice by shrimp processors.

Phosphates are natural components of shrimp and seafood that are involved in providing energy to the muscles. After death, there is a depletion of phosphates, but the addition of phosphates through treatments restores the moisture-binding capacity of the proteins.

It has been documented that phosphates used in conjunction with salt have a synergistic performance, which has led to the addition of salt to phosphate treatments worldwide. In addition, the presence of salt can enhance product flavor.

Proper applications of phosphates and/or salt can result in added sodium of 50 to 250 mg sodium per 100 grams of shrimp meat. Prolonged exposures or higher concentrations result in higher sodium additions.

Other sources of sodium

Buyer aversion to phosphate-treated seafood continues despite the proven sensory benefits and product moisture protection available through the proper use of phosphates. Concerns for excessive water additions or other abuse are the main reasons for the aversion. Other motives include regulatory scrutiny, increases in phosphate prices and potential treatment costs to reduce the residual loads of phosphates in wastewater after processing.

In addition, some regulatory authorities in seafood-producing countries are convinced that phosphates are not allowed by the FDA or European Union, even though phosphates have GRAS status with FDA and are included on the list of approved additives and food colors used by E.U. members.

In general, confusion continues to prevail and buyers remain leery of phosphate use. In response, some processors around the world have begun to use moisture-retention blends of various additives that do not contain phosphates. These mixtures, commonly known as phosphate-free or nonphosphate blends, are formulated with GRAS ingredients (Table 1) such us sodium carbonate and bicarbonate, sodium citrate and salt. These ingredients also appear on the list of approved additives and food colors used by E.U. members.

Garrido, Approved uses of ingredients, Table 1

| Ingredient | United States GRAS Status (Title 21 CFR-1) | European Union (95 2 E.U. Directive) |

|---|

Ingredient | United States GRAS Status (Title 21 CFR-1) | European Union (95 2 E.U. Directive) |

|---|---|---|

| Sodium citrate | No limit * | Permitted in raw and cooked shrimp, no limit |

| Citric acid | No limit * | Permitted in raw and cooked shrimp, no limit |

| Calcium chloride | No limit * | Permitted in raw and cooked shrimp, no limit |

| Sodium bicarbonate | No limit * | Permitted in cooked shrimp only, no limit |

| Sodium bicarbonate | No limit * | Permitted in cooked shrimp only, no limit |

* Used in accordance with good manufacturing practices.

Market trends for “chemical-free” and “natural” seafood have further encouraged the use of phosphate-free blends, despite the fact they still involve various added ingredients. Some processors have converted to using such blends without proper declaration or product labeling based on their assumptions that the ingredients in the blends are undetectable, natural or processing aids not subject to mandatory labeling on the finished products.

Thus, misuse in terms of water additions can continue without phosphates. More importantly, many ingredients in these blends are sodium-based (Table 2), and if used with high concentrations of salt result in high sodium levels in final products.

Garrido, Sodium content in typical moisture-retention agent ingredients, Table 2

| Ingredient | Sodium Content |

|---|

Ingredient | Sodium Content |

|---|---|

| Salt | 39% |

| Sodium bicarbonate | 27% |

| Sodium citrate | 27% |

| Sodium carbonate | 44% |

| Sodium tripolyphosphate | 31% |

| Typical phosphate blend | 30% |

U.S. market survey: sodium in shrimp

A study conducted by University of Florida, USA, researchers that involved testing 152 samples of raw and cooked peeled shrimp collected from retail locations throughout the United States indicated that sodium in raw shrimp products ranged 170 to 1,130 mg per 113-gram serving. This was equivalent to 7 to 50 percent of the recommended daily intake value for sodium. In the cooked products, the levels ranged 100 to 612 mg sodium per 85-gram serving – equivalent to 4 to 25 percent of the recommended daily intake.

Only 31 percent of the samples correctly reported the amount of sodium in the nutrition facts panel. FDA allows a 20 percent variation to account for natural variations of any nutrients in the shrimp. Taking this into account, 53 percent of the samples underreported sodium values in the nutrition facts, while 15 percent reported more sodium than what the products really had. These discrepancies may indicate that some companies may have changed the treatments with MRAs and/or salt but overlooked to perform sodium content analyses of the products.

Sensory evaluations of shrimp

A recent research study at the University of Florida assessed the sensory consequences of treatments with 1.5, 3.0 and 4.0 percent concentrations of phosphates and 0, 1.5 and 2.5 percent salt. The study confirmed that consumers prefer a salty flavor in shrimp products.

Samples with 50 to 400 mg of sodium (0.1 to 0.3 percent salt) were rated as “not quite salty enough.” Samples with 400-500 mg sodium (0.3 to 0.6 percent salt) were rated “just right.” Saltiness was never considered a negative attribute. Treatments as high as 2.5 percent salt did not impart adverse sensory consequences.

Reduction of sodium

Sensory panels and product testing can be used to determine the minimum sodium level or saltiness needed in shrimp for good flavor and high yields. These determinations must take into account that consumers will most likely add more sodium from other sources, such as extra salt, marinades and flavorings.

As a general rule, use of MRAs with raw shrimp can be accompanied with 1 to 2 percent salt. For cooked product, a slightly higher salt concentration is recommended for better flavor, because this particular type of product is frozen and glazed at the plant, and then thawed in running water by consumers – steps that reduce saltiness. Therefore, sensory evaluations at the plant must be conducted not directly from the processing line, but after product is cooked, frozen and thawed following the manufacturer’s recommendations. Sodium can be determined at this point, too, as this will represent the actual amount consumers will intake.

Sodium can also be lowered with the use of low-sodium moisture-retention agents. These have been on the market for a long time, but previous formulations resulted in products with bitter or metallic off-flavors due to the high amounts of potassium.

New blends have a combination of sodium and potassium phosphates and/or sodium-free salts, which results in a lower addition of total sodium but does not affect the flavor of the shrimp. As seen in Table 3, shrimp from the same lot can have different concentrations of sodium depending on the additives used.

Garrido, Levels of sodium in the edible portion of shrimp, Table 3

| Static Treatement, 2° C, 45 MInutes | Total Sodium (mg/100 g shrimp) |

|---|

Static Treatement, 2° C, 45 MInutes | Total Sodium (mg/100 g shrimp) |

|---|---|

| Customary industry treatment: 2.5% phosphate, 2.0% salt | 552 |

| Customary industry treatment: 2.5% phosphate-free blend, 2.0% salt | 600 |

| 3.0% low-sodium phosphate blend | 177 |

| 2.0% salt | 471 |

| Untreated (control) | 305 |

A recent study reported that when using the same concentration of phosphates but different concentrations of salt, the treated shrimp products were perceived less translucent by a trained panel as the concentration of salt increased. This is due to the clouding effect the salt has on the shrimp meat.

Recommendations

Salt and sodium play an important role in the food industry. In shrimp, the presence of saltiness is proven to be a preferred sensory attribute by consumers, and salt was also found to result in better texture due to the increased thaw and/or cook yields. Additionally, use of salt was found to improve the appearance of shrimp.

A recent study by the University of Florida found that, using the same concentration of phosphates with different increasing concentrations of salt, the treated shrimp products were perceived less translucent by a trained panel as the concentration of salt increased. This is due to the cloudiness effect the salt has on the meat of the shrimp.

Due to the health implications of diets high in sodium, the amounts added by moisture-retention agents and/or salt should be limited to only adding the necessary sodium to provide consumers with good flavor, high-yield shrimp.

Consumers on restricted sodium diets make food choices based on the information in the nutrition facts panels. Processors and buyers should periodically verify that the values of sodium in the nutrition facts panels are accurate. Testing for sodium is easy and inexpensive.

Additional Sources of Information

- Shake Your Salt Habit

American Heart Association – 2008

www.americanheart.org/presenter.jhtml?identifier=2106 - The Merck Index, Eleventh Edition

S. Budavari, M. J. O’Neil, A. Smith,

P. E. Hecekelman – 1989

Merck and Company, Inc. – ISBN 911910-28-X - Salt and Sodium: Petition to Revise the Regulatory Status of Salt and Establish Food Labeling Requirements Regarding Salt and Sodium

Department of Health and Human Services

Federal Register – Vol. 72, No. 204 – October 23, 2007 - Salt and Sodium: Petition to Revise the Regulatory Status of Salt and Establish Food Labeling Requirements Regarding Salt and Sodium – Reopening Comment Department of Health and Human Services

Federal Register – Vol. 73, No. 113 – June 11, 2008 - Reducing Sodium: A European Perspective

I. Brandsma – 2006

Food Technology – Vol. 60, No. 3 - Moisture Control to Protect Shrimp Quality: Common Problems, Ethics and Monitoring

L. R. Garrido; W. S. Otwell – 2008

http://shrimpschool.ifas.ufl.edu

(Editor’s Note: This article was originally published in the September/October 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Laura Garrido

Aquatic Food Products Program

Food Science & Human Nutrition Department

University of Florida

Gainesville, Florida 32611 USA -

Steve Otwell, Ph.D.

Aquatic Food Products Program

Food Science & Human Nutrition Department

University of Florida

Gainesville, Florida 32611 USA

Tagged With

Related Posts

Health & Welfare

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

A study demonstrated that VP19 and VP28 white spot syndrome virus envelope proteins expressed by replicon particles provided protection against mortality due to WSSV in shrimp.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 5

The final article in a series about a project in Brunei to develop technology for production of black tiger shrimp focuses on the development of advanced grow-out ponds and practices with enhanced systems for biosecurity, sludge removal, water reuse, energy efficiency, automatic feeding and mechanical harvesting.

Health & Welfare

Biofloc trial results in fast shrimp growth, low FCR, high survival

A trial in a lined, greenhouse-enclosed raceway evaluated the use of a heterotrophic biofloc system equipped with aeration, supplemental oxygen injection and centralized heating to achieve good shrimp production.

Responsibility

Accuracy of custom water analyses varies

The reliability of trace element analyses reported by custom laboratories cannot be checked by simple techniques, and results may not always be accurate. One should check the reliability of major ion analyses by determining the charge balance and comparing the measured total ion concentration with the total ion concentration estimated from conductivity.