Water treatment and utilization of byproducts

Aquaculture waste must be treated to comply with regulations and protect the environment. Many countries have legislation to control the amount of nutrients being released into the environment.

Aquaculture facilities that use water recirculation systems not only limit environmental impact but also have the advantage that several aquatic species can be produced with minimal space requirements. For example, a recycling circuit uses up to 100 times less water than traditional farming systems, and produces less effluent that is more concentrated and therefore easier to treat.

Ongoing research

In France, two research teams are developing integrated systems that include a partial or complete water recirculation system. One team is working on an integrated fish-microalgae-bivalve production system, where silica is added to the fish effluent to produce diatoms that can then be fed to bivalves. Their research is directed toward processing particulate matter by foam fractionation – the choice for bivalve species – and the managing data processing in the system.

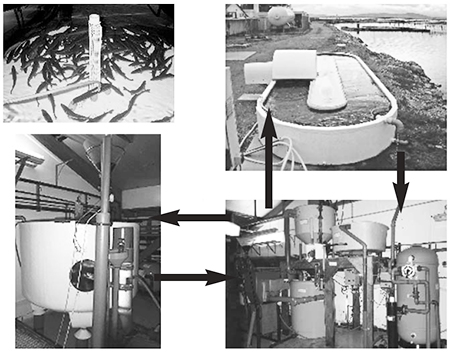

The other team is working on a high rate algal pond (HRAP) system with water recirculation that produces fish and macroalgae. It aims to develop a model of the nutrients in the HRAP that would be added to the existing model of the first loop in order to have a general model of the nutrients in the system. This general model will be used to manage the water flows between the various compartments in order to optimize fish production and water purification in the overall system.

High rate algal ponds

Ammonia nitrogen is toxic to fish at 1 to 5 milligrams per liter, and must be transformed into much less toxic nitrates by nitrifying bacteria in the biological filters. Thus, 90 percent of dissolved inorganic nitrogen is in the form of nitrate. Macroalgae (mainly Ulva sp.) present in high rate algal ponds transform by photosynthesis the dissolved elements (N, P, C) under the double influence of light and temperature.

These algae grow efficiently due to their capacity to live in enriched waters and withstand large variations in temperature, light, and salinity. Their small size (a few cm in diameter) means they can easily be filtered from water.

HRAP are very efficient, with an annual purification of 70 percent inorganic nitrogen and 52 percent inorganic phosphorus. However, purification is not constant throughout the year in Mediterranean countries. Spring and summer are the more favorable seasons because of the longer photoperiod and higher temperature. Nitrogen removal can reach 95 percent and phosphorus up to 85 percent. These yields can fall to 30 percent for nitrogen and 10 percent for phosphorus during the winter.

The water that leaves the HRAP has a high concentration of oxygen and high pH due to photosynthesis. Since this is favorable to the system, the water is recycled through the farm. Such water has been shown harmless to sea bass (Dicentrarchus labrax) fingerlings and adults.

HRAP have an average algal production of 180 to 200 grams of dry weight per day during the summer and 11 to 13 grams of algae per day in winter, with the possibly of more using greenhouses. This byproduct can be exploited several ways.

Integrated systems

The integrated fish production system, which was developed in Israel, uses algae to purify fish effluents rich in ammonia. These algae are used to feed invertebrates, thus allowing other byproducts to be obtained. Such byproducts include various microalgivores like filter-feeding bivalves, and macroalgivores like abalone. The system has the disadvantage of using substantial replacement water, because the purification treatment is still not sufficient to allow all the water to be recirculated.

Conclusion

Aquaculture is a growing industry and its effluents must be properly handled to prevent environmental pollution. Research in this field aims to reduce waste production and lower production and processing costs by creating integrated systems. A better understanding of the transformations of dissolved and particulate matter in these systems is necessary to improve their management.

(Editor’s Note: This article was originally published in the December 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

G. Deviller

IFREMER

Chemin de Maguelone, Palavas-les-Flots, France -

M.A. Franco-Nava

IFREMER

Chemin de Maguelone, Palavas-les-Flots, France -

J.P. Blancheton

IFREMER

Chemin de Maguelone, Palavas-les-Flots, France[114,102,46,114,101,109,101,114,102,105,64,104,99,110,97,108,98,112,106]

Related Posts

Responsibility

Sea and brackish water recirculation systems for round and flat fish production, part 1

Recirculation systems provide a rearing medium that is qualitatively constant and adjustable, resulting in better survival and growth rates.

Responsibility

Automated temperature-controlled recirculation systems

A temperature-control system with a central chiller was found to enhance chilling and research capacity over a system with multiple unit chillers because replicating experiments in a single process control system minimized variations in the temperatures and chilling rates in the individual tanks. Temperature-holding experiments found slight differences at different temperature levels.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Intelligence

A review of European marine finfish hatcheries

As European aquaculture continues to diversify in the marine fish sector, technology advances and methodology in marine finfish hatcheries are proving vital.