Aquastream reduced the variability of survival rates, increased farming cycles, reduced artemia use 97 percent

Many hatcheries believe the quality of Artemia metanauplii has become erratic. At the same time, the sustainability and origin of this live feed have been called into question. New alternatives to artemia diets are therefore being developed and implemented.

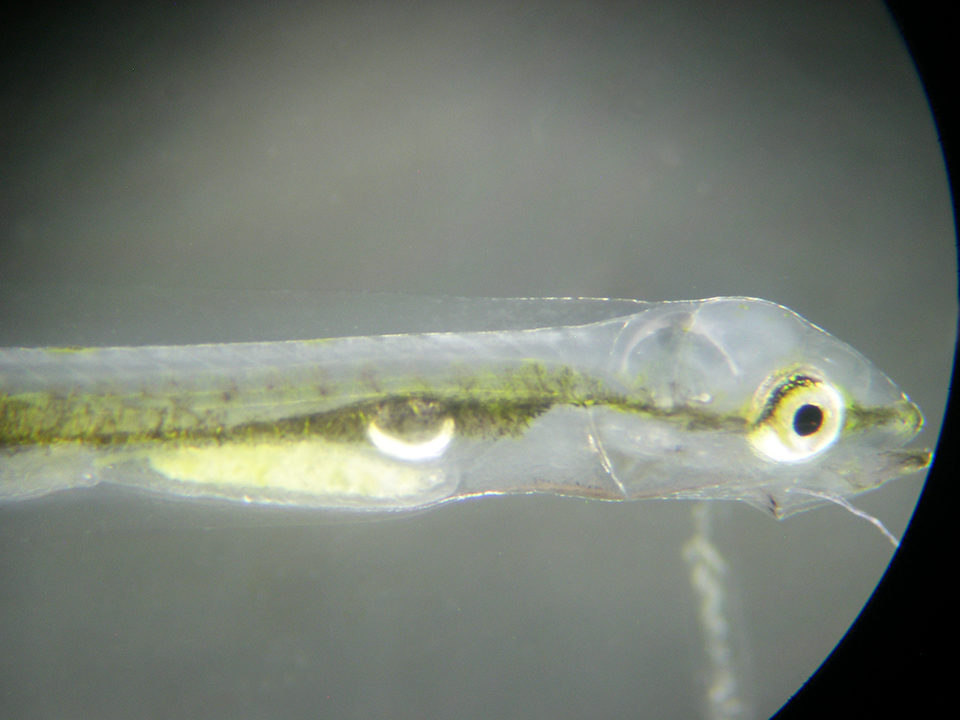

After experiencing disappointing survival rates following traditional artemia-based rearing protocols, the renowned French hatchery Aquastream turned to a micropellet alternative to artemia. The facility found that feeding the extruded pre-starter diet Gemma Micro could produce juvenile Mediterranean sea bass (Dicentrarchus labrax) of high quality while increasing production consistency and significantly reducing costs.

Aquastream seeks alternative

Located in Ploemeur, Brittany, Aquastream produces sea bass fingerlings at its underground hatchery for many of Europe’s leading fish farms. Founded in 2000, the company took the bold step to apply the micropellet feeding protocol to its entire production in 2009, although the decision to move away from artemia use was taken three years earlier.

Between 2006 and 2008, Aquastream experienced 60-day survival rates that fluctuated between 7 and 40 percent with traditional rearing protocols. Disappointed and financially weakened by these results, it set about trying to identify the reasons for the larval mortalities, knowing that its problems were shared by many other European hatcheries. The company’s attention quickly turned toward the live prey artemia, said Nathalie Le Rouilly, production manager for Aquastream.

While this organism provides essential nutrients for the development of marine fish larvae, it is a live animal and therefore quite variable – from its nutritional value and where it is harvested, to how it is enriched and packaged. Artemia can also house bacteria. Feeding live prey to larvae can cause problems such as enteritis and stress. It can also create an imbalance in the rearing environment, which can lead to significantly reduced survival.

“Identifying a problem is one thing; finding a resolution is another,” Le Rouilly said. “We therefore decided to work in parallel on two objectives. The first, to improve the quality of our live prey. The second, to partially or totally substitute the live prey with microparticles.”

Positive results

Aquastream had previously experimented with the micropellet feed with sea bream (Sparus aurata) with some success between 2004 and 2006. In 2008, 25 percent of the company’s larval tanks were dedicated to the development of this new protocol. The results were so positive, the decision to apply the protocol throughout the operation followed the next spring. Since the launch of the new protocol in 2009, Aquastream has invoiced for between 15 million and 20 million fingerlings yearly.

In the last four years, Aquastream has significantly reduced the variability of the 60-day survival rates and increased the number of farming cycles. It has reduced artemia use 97 percent and achieved a 90 percent savings on staff working on the live prey. From a financial perspective, the company has reduced the cost of larval food by close to 45 percent. Looking ahead, the company’s long-term aim is to completely remove the use of artemia.

“For the same costs, we produce at least twice as many fingerlings,” Le Rouilly said. “More importantly, the standardization of our production guarantees the regularity of supplies to our customers, and we can adhere to delivery deadlines planned several months in advance.”

(Editor’s Note: This article was originally published in the January/February 2014 print edition of the Global Aquaculture Advocate.)

Author

-

Eamonn O’Brien

Skretting

Akkerhage 4

9000 Gent, Belgium[109,111,99,46,103,110,105,116,116,101,114,107,115,64,110,101,105,114,98,111,46,110,110,111,109,97,101]

Tagged With

Related Posts

Intelligence

Adding flavor complexity to farmed barramundi

Organoleptic attributes such as flavor and aroma are among the most important factors that influence consumer acceptability and demand for fish products. Consumers have identified farmed fish as less complex and lacking “sealike” or “sea-fresh” flavors and aromas.

Health & Welfare

Dietary acidification in aquaculture

Much of the chemical breakdown of foodstuffs begins in the stomachs of animals through acidification. Effective use of digestive biology is a goal in aquaculture, so dietary acidifiers have been gaining interest in recent years.

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.

Health & Welfare

Acclimating shrimp postlarvae before pond stocking

Shrimp postlarvae acclimation before stocking into the various growout systems (ponds, raceways, tanks) is a critical – and often overlooked, sometimes taken for granted – step in the shrimp culture process. Various water quality parameters should be changed slowly so that the young shrimp have the time to gradually adapt to the new conditions.