Study examines how operators evaluated quality attributes

Shrimp production, the second-largest export earner in the Bangladesh economy, largely relies on extensive farming systems, where safety and quality issues were sometimes not fully addressed until recently. In the aftermath of the 1997 European Union ban on shrimp imports from Bangladesh, shrimp farmers adopted a number of measures to maintain hygiene and sanitation to comply with E.U. legislation. These included maintaining temperature control after harvesting, using plastic crates to hold the shrimp and removal of unsanitary hanging toilets from the farming areas.

Farm survey

Through a study, the author examined how shrimp farm operators evaluated quality attributes with regard to input supply, hygiene and sanitation throughout the production period and post-harvest stage. The study was based on stratified random sampling of 150 shrimp farms raising Penaeus monodon in three locations – Paikgacha, Dacope and Chokoria – in Bangladesh. Data collection was done through interviews, informal discussion and observation using structured questionnaires.

Production factors

At all three locations, farmers applied various types of fertilizers and lime in variable doses during pond preparation and grow-out stages to improve soil and water quality. Urea was used at 14.40-40.93 kg/ha, while triple super phosphate was applied at 7.53-37.18 kg/ha, and cow dung was used at 782.22-987.19 kg/ha. These were absorbed by pond organisms or sediment and did not pose any threat to the quality of shrimp produced.

The survey also showed that farmers were dissatisfied with the quality of hatchery postlarvae, as they experienced higher mortality rates and were often sold without the required information regarding salinity, quantity and size. The farmers complained that postlarvae traders adulterated their stock, and they found it difficult to determine whether hatcheries were using the latest technology.

Harvest practices

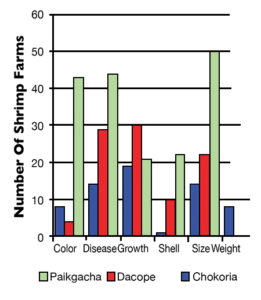

Most farmers (83.3 percent) made a visual evaluation of shrimp by checking size, weight, growth and signs of disease before harvesting. Farmers in Chokoria were more aware of the need to check quality attributes before harvesting than farmers in Dacope and Paikgacha (Fig. 1).

Farmers often ignored icing harvested shrimp at the request of buyers. They took measures when shrimp showed signs of poor quality, such as the presence of spots, soft shells and incidental debris, to minimize losses (Table 1). Farmers addressed spots or petrochemical smells by discarding or burying the affected shrimp. They also cleaned shrimp before selling.

For the most part, farmers did not use chemicals, growth hormones or commercial feed. Nearly all the shrimp farmers raised their quality standards through the use of plastic crates and improved working surfaces to wash, sort and sell the harvested shrimp. About 35 percent improved harvesting areas, and all respondents said they constructed more sanitary toilets a safe distance from farms.

Record keeping was generally poor and below E.U. standards. Some 75 percent of the farmers were largely unaware of their traceability responsibilities, although the registration of shrimp farms is under way.

Alam, Farmers' actions, Table 1

| Quality Concern | Action Taken | Total (%) |

|---|

Quality Concern | Action Taken | Total (%) |

|---|---|---|

| Black spots | Discard, burial | 43.3 |

| Damaged parts | Discard, burial | 61.3 |

| Loose heads | Sold at lower prices | 28.7 |

| Petroleum smell | Discard, burial | 46.7 |

| Soft shells | Cooked at farm | 37.3 |

| Debris and filth | Cleaned and sold | 88.7 |

| Soft texture | Cooked at farm | 42.0 |

Perspectives

Overall, while farmers considered that while changing regulations had improved safety, hygiene and sanitation standards, they had also increased their operational costs.

(Editor’s Note: This article was originally published in the March/April 2013 print edition of the Global Aquaculture Advocate.)

Author

-

Dr. S.M. Nazmul Alam

School of Social Sciences

Curtin University

GPO Box U1987

Perth, Western Australia 6845 Australia

Tagged With

Related Posts

Intelligence

Bangladesh’s tilapia aquaculture industry shows resilience

Tilapia aquaculture in Bangladesh has developed significantly since 1999, based on the Genetically Improved Farmed Tilapia (GIFT) strain of Nile tilapia (Oreochromis niloticus) introduced from Malaysia and on the significant genetic improvement research work by the Bangladesh Fisheries Research Institute (BFRI).

Responsibility

Coastal aquaculture in Bangladesh must adapt to climate change

Shrimp culture in coastal Bangladesh is threatened by climate change variables that include flooding, cyclones, drought, salinity changes and rising sea levels. Holistic planning can help reduce the impacts.

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.