Despite challenges, long-running industry works to expand in global market

Bangladesh is a relatively small country with a large population where agricultural land area has constantly declined and farmers need to increase their incomes from their limited land holdings. Marine shrimp farming in rural Bangladesh emerged as a significant economic activity for traditional farmers in the 1970s and has since gained increasing relevance in generating employment, reducing poverty, and increasing export earnings.

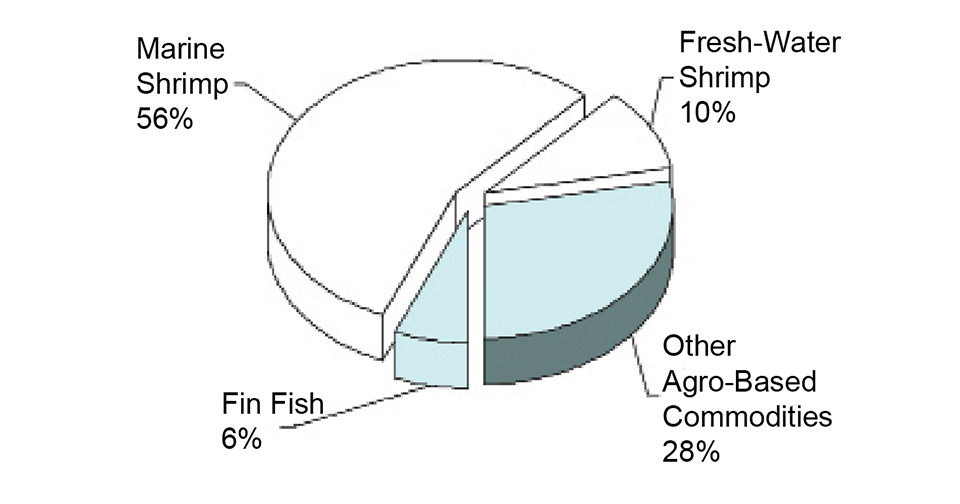

It is estimated that shrimp-based industries in Bangladesh directly employ almost 700,000 people with at least 3 million dependents. With their combined annual contribution of U.S. $360 to 365 million, marine shrimp and freshwater prawn exports rank second only to garments in earning foreign exchange for Bangladesh. Shrimp represented about two-thirds of the value of Bangladesh’s agro-based commodities in 2003-2004 (Fig. 1). Of the total fisheries exports, shrimp contributed 85 percent.

Industry scale

Bangladesh has over 55,000 marine shrimp farms that average about 3 ha in size, although single ponds as large as 40 ha still exist. Currently, marine shrimp farms cover about 170,000 ha in the coastal districts of Satkhira, Khulna, Bagerhat, Cox’s Bazaar, Chittagong, Barguna, and Bhola.

Brackish-water shrimp culture is mostly practiced in the low-lying tidal flood plains within the Bangladesh Water Development Board dikes originally built to reclaim land with potential for agriculture and save human lives and assets from catastrophic tidal action. In many areas, private farmers have also constructed light levees along the river banks for agriculture and aquaculture.

Only those areas adequately inundated during the spring tides are normally used for shrimp farming. Excavation of land to build shrimp ponds is not a common practice. In some places, small domestic ponds connected by tidal creeks are used not only for domestic washing, but also for shrimp and fish culture at various degrees of intensity.

Hatcheries

Currently, some 55 marine shrimp hatcheries at various stages of operation or development are located mostly along the high-salinity southeastern coast of Cox’s Bazaar. Except for a few closed-type hatcheries in the low-salinity southwestern zone, all are open. According to the Shrimp Hatchery Association of Bangladesh, hatcheries produced nearly 7 billion postlarvae in 2004.

Banned for the last four years, the collection of wild fry sadly still continues, although on a much smaller scale than before. The screening of broodstock and postlarvae for viral diseases by polymerase chain reaction testing has just started on a limited scale.

Production technology

Brackish-water aquaculture alternated with farming a variety of salt-resistant, transplanted rice is the general practice. The high-salinity period of February to July is the shrimp-farming season, while rice is cultivated during the nearly fresh-water months of August to December. In some high-salinity areas, aquaculture is rotated with salt production.

The very traditional marine shrimp-farming technology practiced in Bangladesh uses no artificial feeds or antibiotics. Farming is mostly done in association with naturally occurring brackish-water fish and other shrimp species. The mixed culture of black tiger shrimp (Penaeus monodon) with various carps and fresh-water prawns (Macrobrachium rosenbergii) is common in low-salinity areas.

The average stocking rates for black tiger shrimp are typically about 2.5 postlarvae per square meter. Shrimp production averages only 250 to 300 kilograms per hectare per year. Black tiger shrimp is the only marine species cultured, but other shrimp and fish that gain access to the ponds as intruder species also contribute to farms’ income and the diets of locals. Most ponds depend on tides both for water filling and draining.

White spot

White Spot Syndrome Virus (WSSV) and its concomitant shrimp mortality and economic losses have been a recurrent feature since 1994. Closed-system culture using WSSV-screened postlarvae (PL), however, has recently started.

In 2005, closed-system production using stocking rates of 5 to 10 PL per square meter was practiced in about 200 ponds covering 125 ha. These ponds produced an average of 1,300 to 1,400 kilograms per hectare over two crops. Bleaching powder at 60 to 70 ppm is used as a pond disinfectant. More recently, trichlorofon was used at 2 ppm.

Limited culture infrastructure

Shrimp farms, locally called “ghers,” are in most cases paddy fields or salt pans located in tidal flats enclosed by low, fragile levees within the flood control and land reclamation polders built by the government. The ghers are often quite large in area but also quite shallow, typically not exceeding 45 cm. For shrimp farming, water depths of 1.0 to 1.2 meters are more appropriate.

In most cases, shrimp farmers take over agricultural lands on short-term leases of one to three years. No state policy obligates the land owners to culture shrimp themselves or lease their land on a long-term basis, which forces the lease holders to undertake land development work for improved farming. Without assured long-term rights to the land, the lease holders have little incentive to invest in the needed infrastructure.

The lack of a clear land use policy has resulted in conflicts among the coastal land users and the corresponding public sector development agencies. This situation does not promote planned development of culture infrastructure and appropriate sustainable utilization of the scarce land resource. It also creates difficulties in implementing improved culture techniques.

Current issues

Some current issues of concern to the shrimp-farming industry in Bangladesh include the promotion of group farming to benefit small farmers and increased availability of disease-screened postlarvae. Farmers are seeking more inexpensive and effective feeds and pond disinfectants, as well as field kit equipment for quick screening for WSSV.

As a whole, the industry is examining the implementation of higher-yield production technologies that are also economically viable, environmentally friendly, and socially acceptable. It also is promoting the further development and implementation of codes of conduct, as well as product traceability programs.

Bangladesh shrimp and fish foundation addresses food safety, trade issues

Through a variety of programs, the Bangladesh Shrimp and Fish Foundation (BSFF) continues to assist the Bangladeshi aquaculture industry.

BSFF recently completed a study to assess the laboratory equipment and manpower capacities in Bangladesh to analyze shrimp for various hazardous chemicals and antibiotics, particularly nitrofuran metabolites. Except for nitrofuran, all other requirements can be analyzed locally at levels required by the European Union and United States Food and Drug Administration. The Ministry of Fisheries and Livestock is taking measures to procure the equipment to test for nitrofuran metabolites.

BSFF has been awarded an E.U. grant to create awareness among aquaculture industry stakeholders of the various nontariff trade rules, particularly those related to food safety, in the European Union and the need for early compliance to survive global competition. The foundation will also review possible legislative changes to legally obligate the industry stakeholders to abide by the non-tariff conditions.

Following the increasing demand for product traceability in the E.U. and other major shrimp-importing areas, BSFF has introduced a traceability project through the Ministry of Fisheries and Livestock and the Ministry of Commerce. Its goal is to develop a pilot-scale traceability system involving a small number of processors, related farmers, and others in the value chain. A follow-up project will hopefully be undertaken to develop nationwide traceability for shrimp products from point of origin to point of export.

(Editor’s Note: This article was originally published in the April/May 2006 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Dr. Mahmudul Karim

Bangladesh Shrimp and Fish Foundation

House 47, Road 23, Block-B

Banani, Dhaka, Bangladesh[103,114,111,46,110,111,105,116,97,100,110,117,111,102,112,109,105,114,104,115,64,109,105,114,97,107]

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Responsibility

A helping hand to lend: UK aquaculture seeks to broaden its horizons

Aquaculture is an essential contributor to the world food security challenge, and every stakeholder has a role to play in the sector’s evolution, delegates were told at the recent Aquaculture’s Global Outlook: Embracing Internationality seminar in Edinburgh, Scotland.