Kuruma shrimp from Japan boost farmers’ growth rates, market prices

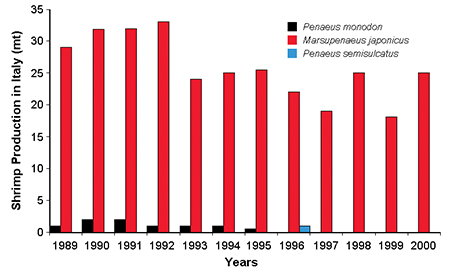

Italy has a high demand for several shrimp species that is mainly met by imports from Ecuador, Argentina, Thailand and Malaysia. The country has, however, successfully developed a relatively small shrimp-farming industry based largely on introduced Kuruma shrimp (M. japonicus). Fig. 1 shows the country’s production of farmed shrimp from 1989 to 2000.

Industry development

The first studies on shrimp culture in Italy go back to the early 1970s, when Febo Lumare applied eyestalk ablation in his work on the reproduction of triple-grooved shrimp (Melicertus kerathurus), a local species. The very slow growth rate of the shrimp made it unsuitable for commercial farming.

In 1981, a batch of Kuruma shrimp was introduced from Japan. Many studies were carried out by Lumare, Ponticelli, and later, Scovacricchi and Canese, to determine growth rates, reproduction and nutrition requirements under local conditions. This species was appreciated by farmers because of its faster growth rate than M. kerathurus and high selling prices (up to U.S. $20 per kilogram). The shrimp were well accepted in the market because of their coloration and other traits.

During the 1990s, other exotic penaeids were introduced and cultured, including P. monodon, P. semisulcatus and Litopenaeus vannamei. P. monodon were farmed from 1989 to 1995 at stocking rates up to 9 animals per square meter. The best production obtained was 1,200 kilogram per hectare in 71 days of culture, with a survival rate of 73.8 percent. However, reproduction of this species in captivity proved difficult.

P. semisulcatus was farmed during 1996 in earthen ponds at stocking rates of 4 animals per square meter. A yield of 581 kilogram per hectare was obtained in 105 days of culture with a survival rate of 76.8 percent. However, prices for P. monodon and P. semisulcatus never reached those of M. japonicus.

Current production

Shrimp farming in Italy is currently based on M. japonicus. The shrimp are cultured extensively (0.5 animals per square meter) in earthen ponds, coastal lagoons, and fishery “valli,” with relatively low yields of 200 to 300 kilogram per hectare and survival rates below 33 percent.

Factors that affect these results include inadequate pond construction and preparation. Ponds generally can not be drained completely, which allows predator species such as European seabass and eels to remain in the basins and prey on shrimp postlarvae after stocking.

Farmers experience high mortality of seedstock. Since seedstock is imported from other European Union countries, losses can climb to 100 percent due to stress from shipping. In addition, feeds imported from Japan cost $1.50 to 8.00 per kilogram, while local formulated feeds are of inadequate quality.

Improved management protocol

Recent research with M. japonicus has established an effective management protocol for production at three to four animals per square meter. This model includes the use of dry chicken manure as organic fertilizer during pond preparation, low water-exchange rates, and less-expensive compound diets to complement natural productivity.

Water quality is improved by promoting phytoplankton photosynthesis during the day and using mechanical aeration during the night. Partial harvests toward the end of the production cycle use selective fyke-net traps.

These practices have produced yields of 852 kilogram per hectare and 23.8-gram animals in 110 days of culture, with a feed-conversion ratio of 1.04 and 91.3 percent survival. (Lumare F., Scordella G., Pastore M., Prato E., Zanella L., Tessarin C., Sanna A., 2000. Pond management and environmental dynamics in semiextensive culture of Penaeus japonicus (Decapoda, Penaeidae) on the northern Adriatic coast of Italy. Riv. Ital. di Acquacol., 35: 15 – 43.)

Industry expansion

A new commercial hatchery in Sardinia that started production in 2001 will supply current domestic seedstock requirements. A new shrimp farm scheduled to begin operations in two years in southern Italy is expected to produce up to 120 metric tons (MT) of M. japonicus. New shipping protocols that incorporate hibernation techniques will open new export markets for live shrimp while complying with the high standards required by international sanitary regulations.

Conclusion

Italy has successfully developed a small shrimp farming industry based on introduced M. japonicus. Current industry expansion is based on the implementation of protocols for improved management and shipping of live product.

(Editor’s Note: This article was originally published in the August 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Giuseppe Scordella

Soc. Coop. HYDRA a r.l.

Via Coppola 1-73100 Lecce, Italy -

Patrizia Zecca

METHODO Scientific Consulting

Lecce, Italy

Tagged With

Related Posts

Innovation & Investment

Aquaculture Exchange: Flavio Corsin, IDH

IDH Vietnam Manager Flavio Corsin speaks passionately about the importance of controlling disease and getting all stakeholders to put competition aside and pull on the same end of the rope. Improvement initiatives for pangasius, shrimp and tilapia are among the Dutch sustainable trade organization’s priorities.

Responsibility

COEXIST project addresses uses, interactions in Europe’s coastal waters

Throughout Europe, debate is taking place as to whether new fish farms, wind farms, tourist facilities or marine and/or coastal protected areas should be established. Competition for space is increasing. In the COEXIST project, partners from 10 European countries are exploring these developments, aiming to increase synergies and reduce conflicts, particularly with regard to the fields of aquaculture and fisheries.

Responsibility

Can ranching ‘zombie urchins’ boost uni, save kelp forests?

With Norwegian knowledge and a partnership with Mitsubishi, Urchinomics aims to turn worthless empty urchins into valuable seafood while restoring kelp forests and creating jobs.

Health & Welfare

Challenges to commercializing shrimp triploidy

Once satisfactory performance is demonstrated in commercial larval rearing and grow-out, automated induction will finalize the triploidy commercialization.