Novel feed attractant for aquaculture

Aquatic animals have stronger smell and taste senses than land animals do. Therefore, in feed formulation for fish and shrimp, feed attractant is always an important additive. The most effective attractant compounds for aquatic animals are free amino acids that are quite abundant in squid and shrimp extracts. Squid liver meal, squid meal, fish solubles, shrimp solubles and other mixtures are often used as feed attractants in the aquafeed industry.

In chitin production from shrimp head waste, the main commercial process is based upon demineralization by acid treatment and deproteinization by alkali treatment. These treatments generate a source of polluted water of high acidity and alkalinity.

In recent years, researchers including Nellie Gagné, Jozef Synowiecki and Asbjørn Gildberg have introduced several enzymatic deproteinization processes as alternative treatments for alkali digestion to reduce the environmental impacts and also produce a protein hydrolysate with a well-balanced amino acid composition.

Producing shrimp soluble extract

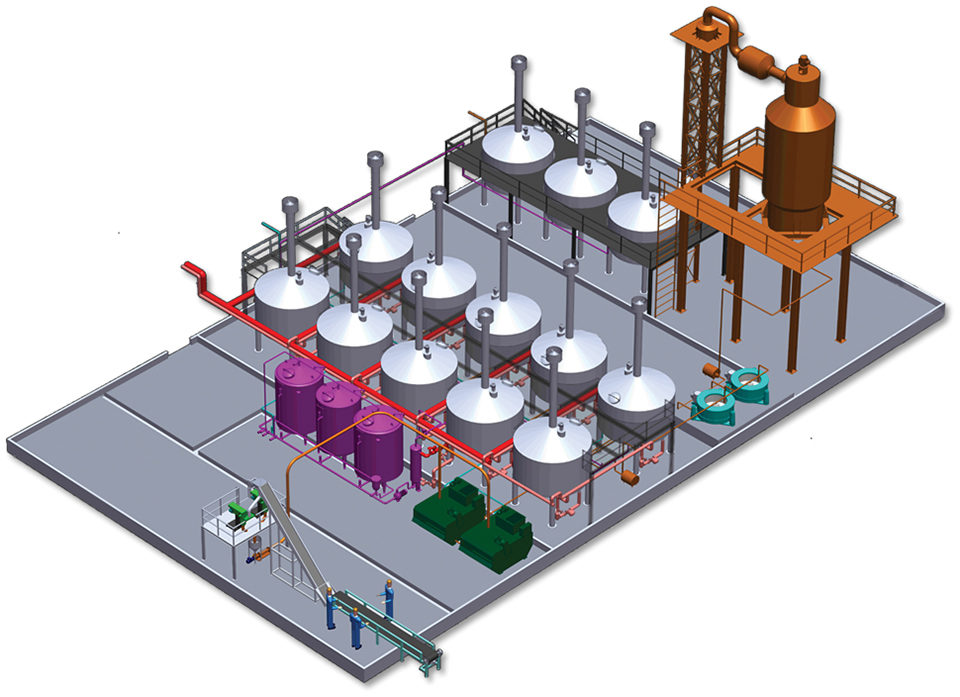

Vietnam Organic, a company based in Ca Mau province, applied the enzymatic hydrolysis process on shrimp head waste to produce a shrimp soluble extract (SSE) that contains a mixture of free amino acids and peptide. The product is a soluble of 20 percent crude protein with protein digestibility of 90 to 95 percent and 11.45 ppm astaxanthin.

The product also contains 1.47 percent aspartic acid, 0.71 percent serine, 2.33 percent glutamic acid, 1.43 percent glycine, 0.56 percent histidine, 1.22 percent arginine, 0.83 percent threonine, 2.17 percent alanine, 1.01 percent proline, 0.23 percent cystine, 0.64 percent tyrosine, 1.14 percent valine, 0.46 percent methionine, 0.95 percent lysine, 0.90 percent isoleucine, 1.43 percent leucine and 1.04 percent phenyl alanine.

Study with tilapia

A study using the SSE product in tilapia feed was carried out in fifteen 500-L composite tanks. Five diets containing fishmeal, soybean meal, rice bran, cassava meal, fish oil and premix were formulated to have 32 percent crude protein and 6 percent lipid.

Diet 1, the control, included 5 percent fishmeal in its composition. Diet 2 was free of fishmeal, while diet 3 had no fishmeal but was supplemented with 2 percent SSE top dressing after pelleting. Diet 4 was free of fishmeal and mixed with 1 percent SSE. Also free of fishmeal, diet 5 was mixed with 2 percent SSE. The formulations of the five diets are presented in Table 1.

Hung, Feed formulation of the five diets, Table 1

| Ingredient | Diet 1 | Diet 2 | Diet 3 | Diet 4 | Diet 5 |

|---|

Ingredient | Diet 1 | Diet 2 | Diet 3 | Diet 4 | Diet 5 |

|---|---|---|---|---|---|

| Defatted rice bran | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 |

| Dried rice bran | 31.40 | 29.50 | 28.40 | 28.90 | 28.40 |

| Soybean meal | 48.80 | 55.20 | 54.30 | 54.70 | 54.30 |

| Fishmeal | 5.00 | 0 | 0 | 0 | 0 |

| Cassava meal | 8.00 | 8.00 | 8.00 | 8.00 | 8.00 |

| DCP | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Methionine | 1.00 | 1.50 | 1.50 | 1.50 | 1.50 |

| Choline chloride | 0.20 | 0.20 | 0.20 | 0.20 | 0.20 |

| Premix | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 |

| Mycotoxin binder | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Vitamin C | 0 | 0 | 0 | 0 | 0 |

| SSE product | 0 | 0 | 2.00 | 1.00 | 2.00 |

Tilapia fingerlings weighing 10 g each were fed the five diets. The fish were stocked at a density of 30/tank and fed three replicates for each diet for eight weeks.

Results

As shown in Table 2, fish that received diet 2 had the lowest growth rate and the highest feed-conversion ratio (FCR). The treatments mixing SSE in the pelleted diet or spraying SSE as a top dressing at 2 percent dosage gave the same growth performance and FCRs as those in the 5percent-fishmeal diet treatment. The survival rates were lowest using the fishmeal-free diet 2 and highest with diet 5.

Hung, Growth and feed utilization of tilapia, Table 2

| Parameter | Diet 1 | Diet 2 | Diet 3 | Diet 4 | Diet 5 |

|---|

Parameter | Diet 1 | Diet 2 | Diet 3 | Diet 4 | Diet 5 |

|---|---|---|---|---|---|

| Initial weight (g) | 10.21 | 10.19 | 10.11 | 10.18 | 10.19 |

| Final weight (g) | 62.69 | 53.06 | 61.15 | 55.73 | 58.59 |

| Weight gain (g) | 52.48 | 42.87 | 51.04 | 45.56 | 48.40 |

| Feed-conversion ratio | 1.41 | 1.48 | 1.39 | 1.46 | 1.41 |

| Survival (%) | 72.22 | 62.22 | 71.11 | 74.44 | 80.00 |

It seemed that mixing 2 percent SSE in tilapia feed improved the survival rates. That indicated the SSE product helped to reduce fishmeal in the diet without affecting growth and feed utilization. Adding the SSE product in the pelleting process could help reduce the feed cost to about $15/metric ton. Other studies to evaluate SSE use in shrimp feed are ongoing.

(Editor’s Note: This article was originally published in the November/December 2014 print edition of the Global Aquaculture Advocate.)

Author

-

Prof. Le Thanh Hung

Faculty of Fisheries

Nong Lam University

Ho Chi Minh City, Vietnam

Tagged With

Related Posts

Responsibility

Properties of common commercial fertilizers in aquaculture

Commercial nitrogen and phosphorus fertilizers are widely used in aquaculture production systems to stimulate phytoplankton growth and the food web that provides natural food organisms beneficial to stocked fish fry and shrimp postlarvae.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 2

The decision to harvest involves consideration of various factors, including market prices, customers’ need, biomass and condition of the animals and others. Several steps are involved, most aimed at maintaining maximum quality of the animals as they are harvested, sacrificed, treated and transported to the plant and processed and packed.

Health & Welfare

The importance of iron in aquaculture systems

Iron is the fourth most abundant element in the earth’s crust, but occurs at very low concentrations in surface waters and oceans. It is an essential element for many organisms as part of many enzymes, and also has an important role in plant photosynthesis.

Aquafeeds

The pink powder that could revolutionize aquaculture

KnipBio, a Massachusetts-based biotechnology startup founded in 2013, is refining the manufacturing process for a promising aquaculture feed ingredient that may one day form the foundation of the food that farmed fish eat.