Effective prevention of discoloration caused by polyphenoloxidase enzymes

The appearance of shrimp is an important factor in the valuation of this product in the market. This is especially important for heads-on shrimp. Consumers usually prefer light-colored shrimp without dark mottling.

Polyphenoloxidase enzymes involved in the molting process of shrimp remain active in shrimp tissue after harvest. Even after shrimp die, the enzymes can cause black pigmentation in shells and on the flesh.

Shrimp are placed on ice at harvest, but this does not always stop the action of polyphenoloxidases. Sodium bisulfite, however, quickly deactivates the enzymes. Shrimp often are dipped in bisulfite solutions at harvest and again at the processing plant to prevent black spotting.

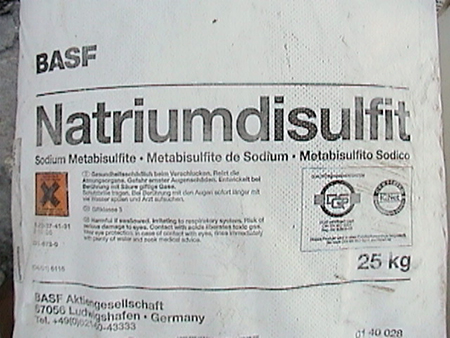

Sodium bisulfite and metabisulfite

Sodium bisulfite and sodium metabisulfite are common industrial chemicals widely used as bleaches, disinfectants and antioxidants. Their chemical formulas are NaHSO3 and Na2S2O5, respectively. When sodium metabisulfite is dissolved in water, it hydrolyzes to form sodium acid sulfite (also called sodium bisulfite). Thus, the same solution is achieved when either sodium bisulfite or sodium metabisulfite are dissolved in water.

Postharvest treatment

The usual procedure at harvest is to dip shrimp in a 5 percent solution of sodium bisulfite for 2 to 5 minutes, with the objective of producing a bisulfite concentration of 30 to 50 ppm sulfur dioxide equivalent in the shrimp.

After the shrimp are treated with chlorine, processing plants often also use a 5 percent sodium sulfite solution, but vary the exposure time depending upon product destination. Usual limits for concentrations of sulfite in the flesh are 30 ppm for Japan, 80 ppm for the European community and 100 ppm for the United States.

Sodium bisulfite solutions are not completely consumed during use as shrimp dips. The remaining solution is a waste that is sometimes discarded into the environment. This liquid waste can cause negative impacts if discharged directly into natural waters.

Chemical reactions

Sodium bisulfite solutions react with dissolved oxygen to form sodium acid sulfate. Sodium acid sulfate solutions are acidic. The hydrogen ions responsible for acidity result because sodium acid sulfate dissociates into sodium and bisulfate ions, and bisulfate ions further dissociate into sulfate and hydrogen ions. The hydrogen ions will cause pH and total alkalinity in receiving waters to fall by neutralizing bicarbonate.

Each milligram of sodium bisulfite can consume 0.15 milligrams per liter of dissolved oxygen. With a strength of 50,000 milligrams per liter, a 5 percent solution of sodium bisulfite can react quickly with a large amount of dissolved oxygen. Each milligram of sodium bisulfite can result in enough hydrogen ions to reduce total alkalinity concentration by 0.48 milligrams per liter.

Impact example

Suppose that 5 cubic meters of a 5 percent solution of sodium bisulfite is discharged into a stagnant canal 1 km long, 50 meters wide, and 1 meter deep (a volume of 50,000 cubic meters). The solution contains 250 kg of sodium bisulfite and could remove 37.5 kg of dissolved oxygen and 120 kg of total alkalinity from the water in the canal.

If the sodium bisulfite solution is quickly and thoroughly mixed into the canal, it will lower the concentration of dissolved oxygen by only 0.75 milligrams per liter and total alkalinity by only 2.04 milligrams per liter. The pH probably will not change by a detectable amount, for the loss of alkalinity (and buffering capacity) are slight.

However, in a stagnant canal, it takes a long time for the sodium bisulfite solution to mix thoroughly with the water. In the area where the sodium bisulfite solution is released, the bisulfite concentration will be very high. Depletion of dissolved oxygen could occur, and the large decline in total alkalinity could cause a drastic decline in pH. The net effect could be to stress or kill aquatic organisms in the canal.

Responsible disposal

The example above illustrates why spent sodium bisulfite solutions should not be discharged into natural waters. Procedures should be developed for responsible deactivation of sodium bisulfite.

Deactivation

Deactivation of sodium bisulfite by treatment with calcium hypochlorite or other chlorine compounds represents a safety hazard for workers. When chlorine compounds are mixed with acidic solutions, highly toxic chlorine gas can be released. A small release of chlorine gas can be harmful or even lethal to workers, especially if it occurs in a poorly ventilated space. If such treatment is used, appropriate protective gear is required to protect workers.

Oxidation and neutralization

A safer way to deal with sodium bisulfite waste is disposal in oxidation lagoons or other wastewater treatment systems designed to treat pond or processing plant effluents. The waste will be oxidized and neutralized within these systems before its final discharge into a receiving water body.

If no treatment system is available, the solution can be placed in a tank and mechanically aerated until the bisulfite is oxidized to bisulfate and the resulting acidic solution neutralized with calcium hydroxide or sodium hydroxide. The extent of aeration needed can be determined by monitoring the dissolved oxygen concentration. When the concentration stabilizes above 4 or 5 milligrams per liter, the bisulfite has been oxidized. Each kilogram of sodium bisulfite will require 0.36 kg of calcium hydroxide or 0.38 kg of sodium hydroxide.

Upon oxygenation and neutralization, the solution can be safely discarded into natural waters. Alternatively, the solution could be held for a longer period in a small pond or large tank for natural oxygenation. Upon complete oxidation of the bisulfite, the solution could be neutralized with hydrated lime or other base.

Conclusion

Sodium bisulfite dips of harvested shrimp are an effective course of treatment to prevent discoloration caused by polyphenoloxidase enzymes in the animals. Improper sodium bisulfite waste disposal, however, can cause negative impacts if discharged directly into natural waters. Responsible disposal of sodium bisulfite solutions does not represent a major effort or expense, and should be implemented on shrimp farms and at processing plants.

(Editor’s Note: This article was originally published in the August 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Claude E. Boyd, Ph.D.

Department of Fisheries and Allied Aquacultures

Auburn University

Auburn, Alabama 36849 USA[117,100,101,46,110,114,117,98,117,97,64,49,101,99,100,121,111,98]

-

Dominique Gautier, Ph.D.

Grupo Granjas Marinas

Choluteca, Honduras

Related Posts

Health & Welfare

Harvesting head-on shrimp

EU markets have special requirements for head-on shrimp. Organoleptic criteria are evaluated, including firmness of shell and head, malformations and color.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 1

Harvesting a crop of shrimp is a critical step for any shrimp farming venture. Several months of efforts and resources to properly raise a quality crop have already been invested, and this quality must be preserved. The decision to harvest involves consideration of various factors.

Intelligence

The proper use of brine to freeze shrimp, part 1

Brine freezing of shrimp at processing plants by immersion in a chilled, aqueous brine solution is commonly used to chill the shrimp after cooking, and requires much less energy than other traditional methods. It results in very small ice crystals forming in the shrimp tissue, minimizing drip loss.

Intelligence

4-hexylresorcinol: sulfite-free control for melanosis in crustaceans

4-hexylresorcinol in a nonsulfite processing treatment against melanosis in crustaceans inhibits natural enzymes for shell hardening.