Water temperature, salinity, exposure time affect feed stability

Once immersed in water, aquatic feeds are expected to be fully consumed and converted into high-quality protein for human consumption. This process in fact involves a complex set of factors and conditions that must be well understood to avoid unnecessary fertilization and wasted money for farmers.

Studies have shown that temperature and salinity levels play key roles in nutrient metabolism in aquatic animals, affecting, for example, protein and amino acid requirements and digestibility, energy budgets and mineral requirements. In addition to chemical aspects, effects upon feed pellet integrity through reduction of physical stability and increased nutrient leaching can lead to decreased feed nutritional value.

Marine shrimp are farmed under distinct environmental and water quality conditions according to region and season that may range from fresh to hypersaline waters. Considering the impacts of environmental effects and the diversity of farming conditions, studies taking into account these interactions and feed stability could bring practical information to shrimp farmers.

Physical stability

Physical stability is a critical factor in feed processing that starts with ingredient selection and goes through feed processing to feed management. As selective and rather slow feeders, shrimp require a higher degree of physical stability in feeds than those found in feeds for finfish such as tilapia and salmon.

On the other hand, water uptake and leaching of soluble components have been positively associated with signaling, feeding stimulation, palatability and, hence, feed consumption. The advantages and disadvantages of high physical and chemical stability in shrimp feeds are summarized in Table 1.

Dias, Advantages and disadvantages of high physical and chemical stability, Table 1

| Advantages | Disadvantages |

|---|

Advantages | Disadvantages |

|---|---|

| Reduces nutrient leaching | Reduces stimulatory effect |

| Reduces dissolved solids | Increases ingestion time |

| Increases nutrients available in pellets | Raises processing costs |

| Facilitates solids removal | Restricts certain ingredients |

Brazilian feed study

The authors conducted a study funded by FAPESP at the Marine Aquaculture Laboratory at the University of Sao Paulo in Brazil to evaluate the stability of six commercial feeds under temperature and salinity conditions that occur in shrimp farms in northeastern Brazil, where most of the Brazilian shrimp industry is located. The abiotic data was collected during the Brazilian Shrimp Farmers Association’s water quality-monitoring project in 2002 and 2003, which ranged over 1,600 km.

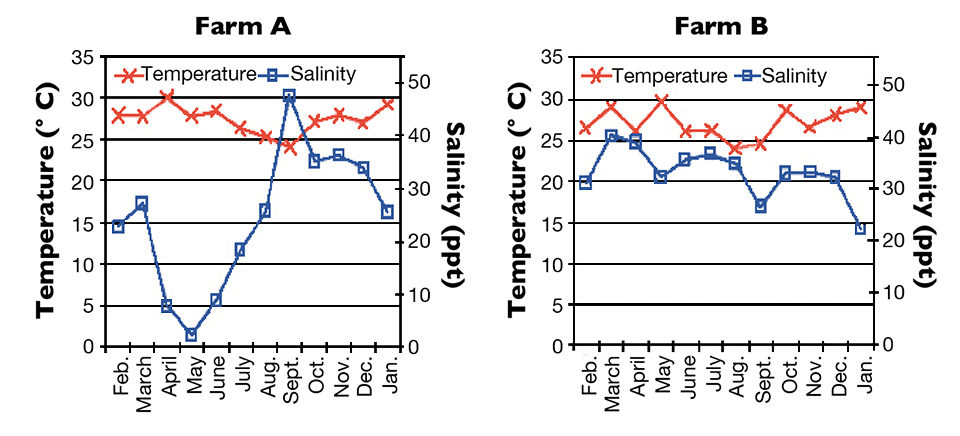

Pond water salinity at the shrimp farms in northeastern Brazil presented different patterns, as shown in Figure 1. For instance, farm A showed a much wider salinity range through the year in contrast to farm B. Monthly temperatures of 24, 27 and 30 degrees-C, and salinities of 5, 19, 33 and 47 ppt were selected as baseline parameters for the study.

A temperature-controlled water bath shaker with horizontal motion was utilized to reproduce leaching in field conditions. Ocean water was diluted with distilled water for the tests in lower salinities, and hypersaline water was prepared after recovery of aliquots of frozen stocks of marine water.

Three 2-g replicates per feed tested were immersed in 250-mL conical flasks at the established temperatures and salinities. After 30, 60, 120 or 240 minutes in static and shaking conditions, the recovered dry matter was vacuum filtered, gently rinsed with distilled water for salt removal and dried for mass calculation.

Findings, applications

Immersion time, agitation method

Dry matter loss increased with immersion time until it reached 9.7 percent under shaking conditions after 240 minutes. than under static conditions for the same period. Further effects to consider on dry matter loss under farming conditions include aeration, feeding method and water dynamics – together with the control of feed conversion, since unconsumed feed is subject to nutrient loss and deteriorates water quality.

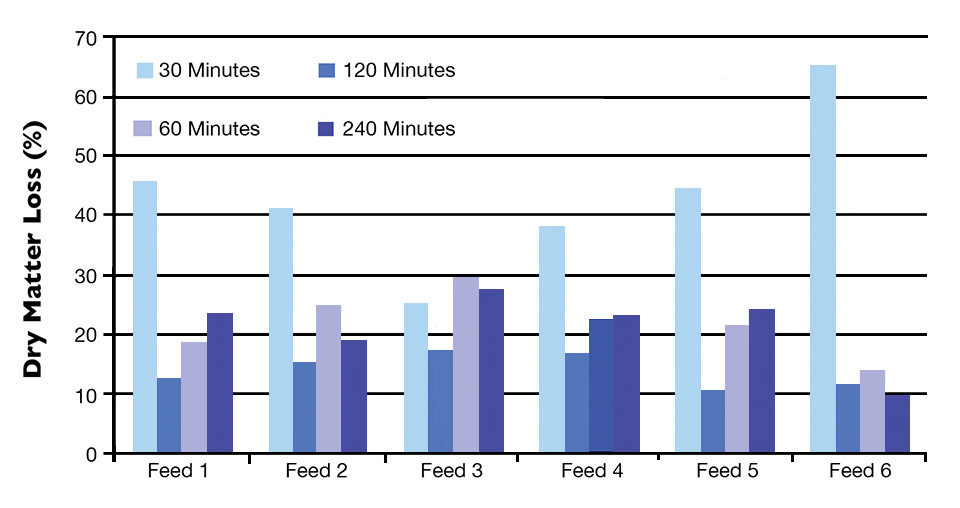

Once feed enters the water, the faster it is ingested by the shrimp, the better. The first half hour is critical because, for most of the tested feeds, almost 50 percent of the dry matter loss occurred during this period. One feed tested, however, showed higher dry matter loss after 120 minutes in contrast to another feed for which almost 65 percent of the leaching occurred in the first 30 minutes of immersion (Fig. 2).

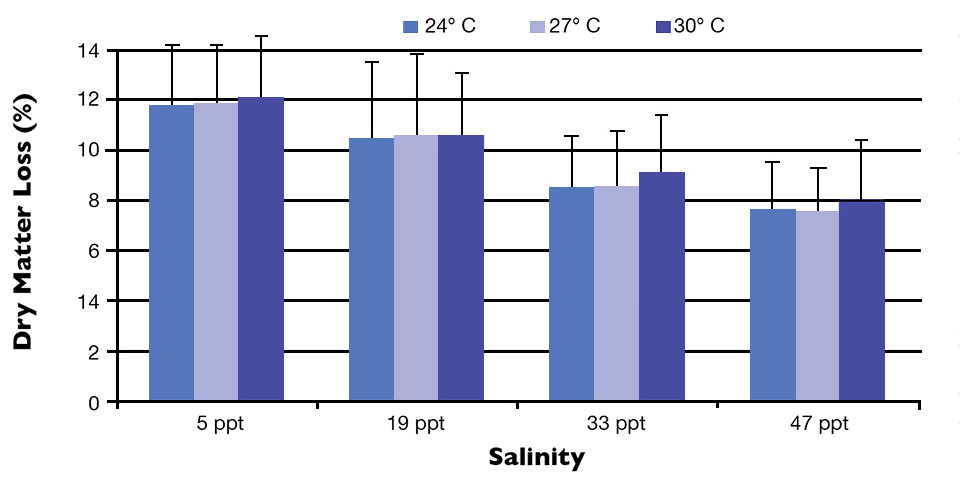

Temperature, salinity

The use of the same feed under different salinities can result in different leaching patterns. Dry matter loss was more pronounced in oligohaline waters than in the hypersaline, as shown in the 5 and 47 ppt salinities that respectively reflected the extremes of this parameter at the shrimp farms surveyed. In contrast to salinity, the effect of temperature upon dry matter loss was negligible for the temperature range observed (Fig. 3).

Shrimp farms supplied by low-salinity waters during whole or part of the production cycle should take special measures to counteract the higher leaching of nutrients through the selection of more stable feeds and/or improved feeding management.

The selection of the right feed can be decisive, as feeds present distinct leaching interaction patterns mainly related to salinity and immersion time. While some feeds presented similar dry matter loss when immersed in 5 ppt after 30 minutes or 47 ppt after 240 minutes, others presented losses two times higher at 47 ppt after 240 minutes in comparison to 5 ppt water after 30 minutes.

It appeared that dry matter loss was more pronounced in highly stable feeds as salinity decreased. While a more stable feed lost 140 percent more dry matter when salinity dropped from 47 to 5 ppt, a less stable feed lost only 58 percent more dry matter in the same shift.

Perspectives

The commercial feeds evaluated showed distinct leaching patterns that may reflect the technologies and ingredients employed in their processing. These processes need to be further investigated in order to develop feeds that withstand varied farming conditions in different seasons and feeding regimes. On the other hand, farmers should be aware of the suitability of feeds before supplying them to their animals.

Feed stability studies applied to practical farming conditions can benefit feed processors through monitoring and anticipating feed physical features. However, little is known about interactions among ingredients, processes, physical characteristics and the effects on shrimp ingestion efficiency. In this sense, combining feeding behavior assessment and feed processing should help advance efforts toward increased nutrient delivery for the animals with minimal negatives for the environment.

(Editor’s Note: This article was originally published in the November/December 2009 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Raul Dias

Marine Aquaculture Laboratory

Oceanographic Institute

University of São Paulo

Praça do Oceanográfico 191

São Paulo 05508-900 Brazil -

Rodrigo Carvalho, M.S.

Marine Aquaculture Laboratory

Oceanographic Institute

University of São Paulo

Praça do Oceanográfico 191

São Paulo 05508-900 Brazil -

Daniel Lemos, Ph.D.

Marine Aquaculture Laboratory

Oceanographic Institute

University of São Paulo

Praça do Oceanográfico 191

São Paulo 05508-900 Brazil -

Albert G.J. Tacon, Ph.D.

Aquatic Farms Ltd.

Kaneohe, Hawaii, USA

Related Posts

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Responsibility

A look at integrated multi-trophic aquaculture

In integrated multi-trophic aquaculture, farmers combine the cultivation of fed species such as finfish or shrimp with extractive seaweeds, aquatic plants and shellfish and other invertebrates that recapture organic and inorganic particulate nutrients for their growth.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.