Total ammonia nitrogen, water temperature and salinity, organic carbon are important variables

It is widely recognized that the rate of nitrification in biofiltration is greatly influenced by numerous water quality variables. Assuming that flow does not limit the rate of nitrification in a biofilter, perhaps most important are the concentration of total ammonia nitrogen (TAN) in the system water, water temperature and salinity, and the amount of organic carbon in the system water.

Quantifying nitrification

Historically, studies have reported nitrification rates based upon media specific surface areas, with value placed on higher SSA values. In theory, the greater the SSA, the more living space for bacteria. In an ideal world, this would translate into higher nitrification rates.

In the real world of commercial aquaculture, however, the bacteria create a biofilm that can effectively cover the media, possibly in a way that clogs the topographic or porous features of the media designed to increase the specific surface area. This covering of the media essentially creates new media topography and reduces the actual surface area used by the bacteria.

Volumetric TAN conversion rate

Thus, the theoretical nitrification capacity of a particular filter media based on SSA does not always reflect the actual nitrification achieved in the real world. Recently, it has been suggested that biofilter nitrification rates should be based upon TAN conversion per unit of unexpanded media volume. Referred to as the volumetric TAN conversion rate (VTR), typical units for this standard measure of nitrification are grams of TAN removed per cubic meter of biofilter media per day.

The accuracy of this measurement of nitrification is not inclined to error introduced by assumptions of the inhabitable surface area of the biofilter media. It is a direct measure of the capacity of the filter based on its easily measurable volume.

TAN concentration effects

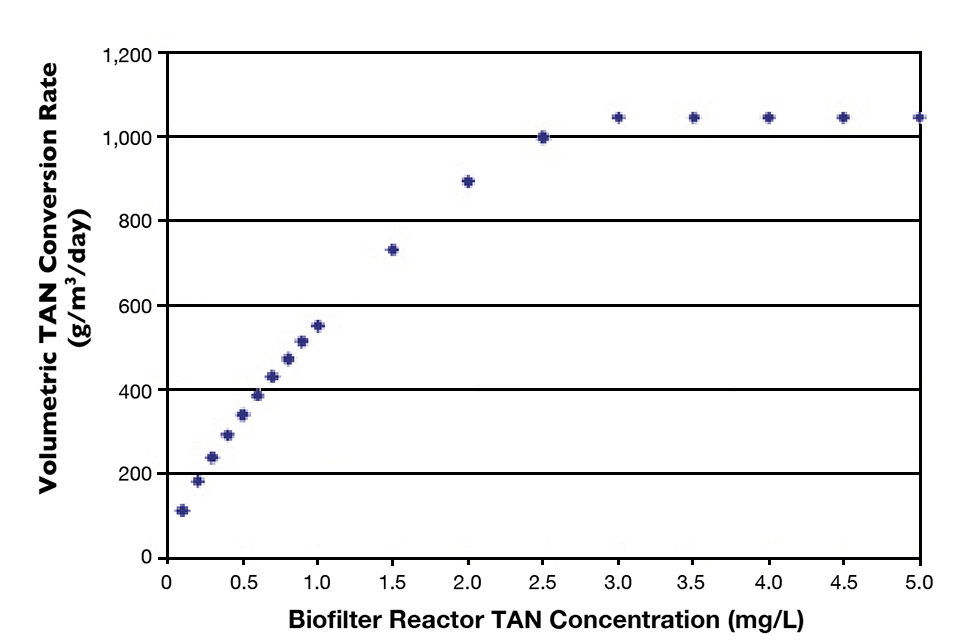

Under most conditions encountered in commercial aquaculture, TAN concentrations are maintained below 2 mg/L. At these levels, there is generally a linear relationship between the TAN conversion rate and TAN concentration in the filter. When values rise much above 3-4 mg TAN/L, there is usually no further increase in the rate of nitrification.

Fig. 1 is an example of the relationship of the TAN concentration in a biofilter reactor to the VTR used in a recirculating aquaculture system (RAS). The slope of the near-linear relationship and peak of the nitrification rate are specific to the biofilter media and system water quality. Keep in mind that the rate of nitrification can be limited by other water quality parameters, such as dissolved-oxygen concentration, temperature, salinity and concentration of dissolved organic carbon.

Additionally, the turnover rate and physical movement of ammonia nitrogen from the culture tank to and through the biofilter can limit the activity of a biofilter. The designer should pay close attention to the required concentration of TAN leaving the biofilter. In general, the lower the TAN concentration, the larger the biofilter will need to be.

Organic carbon concentration

Dissolved organic carbon in RAS comes from the degradation of the feces from the cultured organisms and the degradation of uneaten feed. In general, heterotrophic bacteria degrade and metabolize dissolved and particulate organic matter. Autotrophs and heterotrophs compete for space on biological filter media while they create the biofilm.

Competition for nutrients and oxygen between these two types of bacteria results in a stratified biofilm structure. The faster-growing heterotrophic bacteria tend to occupy the outer layer of the stratified biofilm, where substrate concentration and detachment rates are both higher. Slower-growing nitrifying (autotrophic) bacteria occupy the inner biofilm layer.

Heterotrophic bacteria have been shown to have growth rates five times greater than those of autotrophic bacteria. By covering the nitrifying bacteria, heterotrophs reduce the diffusion of ammonia-nitrogen and dissolved oxygen to the nitrifying bacteria, thus negatively reducing the rate of nitrification by the biofilter.

Decreased nitrification rates have undesirable effects on water quality, including higher TAN concentrations, and create stress on the culture animals. As the ratio of organic carbon to ammonia-nitrogen increases to 1:1, a reduction of over 70 percent of the nitrification rate in the biofilter can be seen. As such, uneaten feed and feces should be removed from the process flow as quickly as possible – and certainly before the flow enters the biological filter.

Placement of a mechanical filter directly before the biological filter will result in maximum removal of particulate organic matter, ultimately improving the biological filter nitrification rate.

Temperature effects

The influence of temperature on nitrification in fixed biofilm processes like those in a biofilter is more complicated than that on the suspended growth processes found in domestic wastewater treatment. In suspended growth reactors, higher biological reaction rates are observed as the system reaches an optimum temperature, above which rates usually decrease. Predicting the effects of temperature on a fixed-film bioreactor is difficult because, as noted above, the diffusional transport of nutrients and oxygen into the biofilm is of major importance to the nitrification rate.

Studies have shown the effects of temperature on nitrification in aquaculture biofilters are less significant than previously thought. Dissolved oxygen (D.O.) may become more of a limiting factor at higher temperatures due to the diffusion process limitation of oxygen flux.

The D.O. saturation concentration in water decreases as temperature increases. Thus, studies have shown that oxygen limitation usually has more impact on biofilter performance at temperatures between 14 and 27 degrees C than temperature variation does.

Perhaps the most important message from this is that more attention should be paid to organic carbon concentration build-up in recirculating system water. Since commercial RAS operate at low TAN concentrations and high feed rates, the resulting organic loads play a much larger role in biofilter performance than temperature or almost any other water quality parameter.

Salinity effects

Marine species in general tend to be more sensitive to elevated levels of ammonia-nitrogen concentrations. Therefore, a system with saltwater may need to be designed to maintain lower concentrations of TAN. There is a relative abundance of published information on nitrification for freshwater systems, compared to the information available on seawater systems.

There has been some debate about the effects of seawater on nitrification. Several studies showed the rate of nitrification in saltwater biofilters was approximately 40 percent lower than in similar freshwater systems. Therefore, when designing marine RAS, one must take into account both the lower level of tolerance of TAN by marine species and the fact that biofilters have reduced capacity in saltwater. It is safe to say that in most cases, marine biofilters should be larger than freshwater biofilters for the same feed rates.

Editor’s Note: This article was based on information by the authors presented in chapter 31 of the 2009 publication New Technologies in Aquaculture: Improving Production Efficiency, Quality and Environmental Management, published by Woodhead Publishing, Ltd.

(Editor’s Note: This article was originally published in the May/June 2015 print edition of the Global Aquaculture Advocate.)

Authors

-

Thomas M. Losordo, Ph.D.

Principal Scientist and Chief Engineer

Pentair Aquatic Eco-Systems, Inc.

400 Regency Forest Drive, Suite 300

Cary, North Carolina 27518 USA[109,111,99,46,114,105,97,116,110,101,112,64,111,100,114,111,115,111,108,46,109,111,116]

-

Dennis P. DeLong, MSM

Manager of Customer Advocacy

Pentair Aquatic Eco-Systems, Inc. -

Todd C. Guerdat, Ph.D.

Professor

Manchester Community College

Manchester, New Hampshire, USA

Tagged With

Related Posts

Health & Welfare

Biofilter inoculation in recirculating aquaculture systems

Biological filters are essential parts of recirculating aquaculture systems that transform toxic fish compounds such as ammonium and nitrite into less-harmful nitrate. The authors tested the convenience and efficiency of three methods for the initial inoculation of aerobic biofilters.

Aquafeeds

Aquaculture feed composition helps define potential for water pollution

A study found that feed for salmon and trout had higher organic carbon concentrations than did catfish, shrimp and tilapia feeds. Nitrogen and phosphorus concentrations were similar among salmon, trout and shrimp feeds, and higher than those in catfish and tilapia feeds.

Innovation & Investment

Estimating biofilter size for RAS systems

Controlling total ammonia-nitrogen (TAN) concentrations is the primary concern when sizing a biofilter for use in a recirculating aquaculture system. Sizing decisions are best based on previous experience with a given biofilter media in a specific biofilter configuration.

Responsibility

Optimizing tilapia biofloc technology systems, part 3

The economic and environmental performance of tilapia biofloc technology systems are compared against other conventional tilapia grow-out production systems, highlighting the merits of BFT as a competitive and sustainable alternative low-cost intensive feedlot technology.