Results show potential for drastically reduced footprint for carnivorous finfish production

Reliance on marine-sourced fishmeal and fish oil is a primary limiting factor in the growth, profitability, and sustainability of the marine finfish aquaculture industry. For the species kampachi (almaco jack, Seriola rivoliana), several alternative ingredients have proven successful as partial replacements of fishmeal or fish oil – an important biological proof – but few ingredients meet the range of criteria necessary for commercialization.

In addition to reliable nutritional quality, successful alternative diets must be palatable to the species in question, must not alter the quality of the final product for consumers, and must be affordable. Despite several research-scale successes, commercial Seriola production in 2020 still utilizes diets primarily based on fishmeal and oils derived from wild-caught forage fish.

Through the U.S. National Oceanic and Atmospheric Administration (NOAA) Saltonstall-Kennedy Grant Program, Ocean Era (formerly Kampachi Farms), Aquatic Feed Technologies and the F3 Future of Fish Feed team have worked together to create fish-free feeds for S. rivoliana that not only yielded competitive performance but were formulated with ingredients that are both abundant and cost-effective. Specifically, ingredients of interest were byproducts from the natural spirulina pigment market, low-cost poultry meal, and Veramaris™ algae oil. Poultry meal used in these diets was all pet-food grade (PFG).

The scope of the grant involved three separate grow-out trials for S. rivoliana from 2018 to 2020, with diet formulae evolving based on the results, and this article focuses on the results of the final trial in the series.

This material is based upon work supported by NOAA under contract number NA18NMF4270208. Any opinions, findings, conclusions or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of NOAA.

Study setup

The study was conducted in April 2020 at Ocean Era (Hawaii, USA) with 480 juvenile S. rivoliana randomly distributed into sixteen 4-ton tanks to initiate a comparative grow-out trial. The four treatments included a commercial control diet, and three fishmeal-free formulations with a shared base of pet-food grade poultry meal, wheat, soy protein concentrate and corn protein. One diet was identical to a formulation that had proven successful in the preceding Trial 2 (PM+FO); one diet replaced all fish oil in that formula with a blend of canola, flax, and Veramaris™ algae oils (PMnoFO); and one incorporated spirulina as a primary protein (PM+Spiru). Complete formulations are open access, available through the F3 Feed Innovation Network.

Diets were randomly assigned to each experimental tank in quadruplicate; tanks were originally stocked at 30 fish per tank and culled to 15 fish per tank at the start of Month 2, as dictated by density limitations. Fish were 145 days post-hatch at trial start, averaging 282 grams. Total trial duration was three months. Prior to trial start, all fish were held on a different commercial yellowtail feed in order to minimize any acclimation bias for the experimental feeds; all fish were subject to a diet change at trial start, including the Control fish (from one commercial diet to the Control commercial diet).

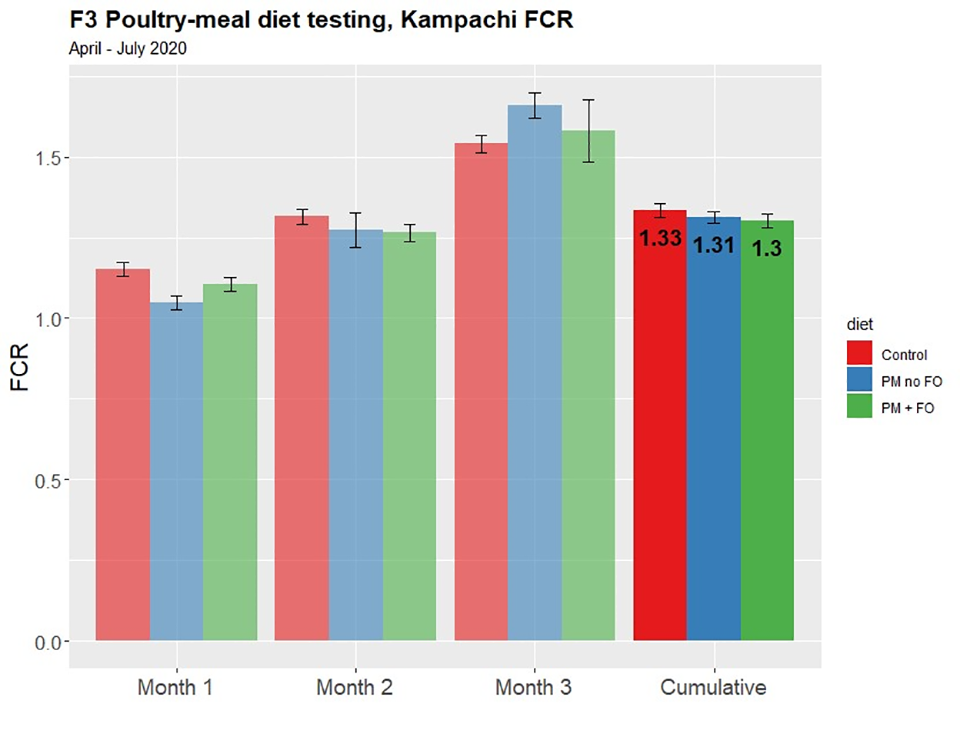

Fish were initially fed twice daily, switching to once daily when they reached approximately 1-kg average weight. Every four weeks, all fish were anaesthetized, weighed and measured (fork length). The biological feed conversion ratio (FCR) was calculated based on feed consumption and weight gain over the four-week intervals.

At trial completion, three fish from each tank (12 per treatment) were randomly selected for processing. Whole fish were weighed for total body weight, then viscera were removed and weighed separately to calculate viscerosomatic index, VSI (relationship between fish body weight and liver weight). Each fish was filleted, then right and left fillets (ribs on) were weighed separately, and the combined fillet weight was compared to whole fish weight to obtain percent yield. All fish were filleted by the same person to account for technique variation.0

Results and discussion

Because its results were confounded by rancidity issues, we removed the data from the spirulina diet (PM+Spiru).

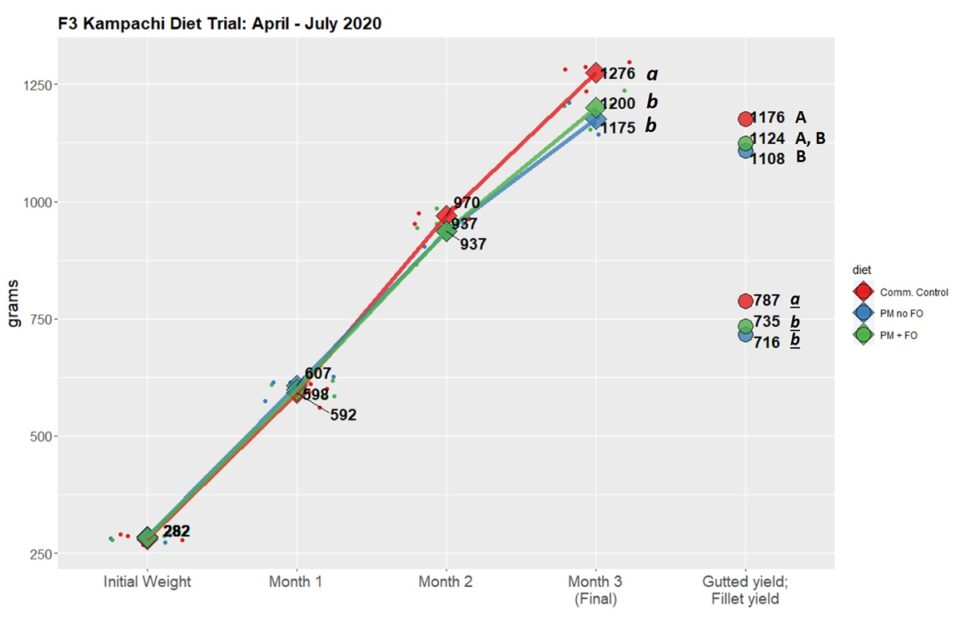

Regarding average weight and yield, all dietary treatments started at the same size – a combined average of 282 grams. Diets PMnoFO and PM+FO were statistically equal with the Control through the first two months but fell behind over Month 3. The Control treatment produced the largest fish to a significant degree (p<0.05); PMnoFO and PM+FO were comparable to each other.

This contrasts with results from the previous trial in the series, where the PM+FO treatment was statistically equivalent in final weight to the Control. This trial was to replicate those results, but instead showed a 6 percent size discrepancy.

Meigs, Kampachi, Table 1

| Treatment | Initial | Month 1 | Month 2 | Month 3 | Statistical relation |

|---|

Treatment | Initial | Month 1 | Month 2 | Month 3 | Statistical relation |

|---|---|---|---|---|---|

| Control | 280 ± 41 | 592 ± 76 | 970 ± 103 | 1276 ± 143 | a |

| PM no FO | 280 ± 41 | 607 ± 78 | 937 ± 103 | 1175 ± 128 | b |

| PM+FO | 280 ± 47 | 598 ± 80 | 937 ± 108 | 1200 ± 120 | b |

Average VSI for the control was significantly higher than both experimental treatments. When applying these discard rates to the whole fish weight, the disparity between the final yields diminishes. The PM+FO treatment is statistically comparable to the control in terms of whole, gutted fish. This altered relationship does not hold in terms of fillet yield, which was the same across all diets.

The results regarding VSI are consistent with previous grow-out trials in this series: The treatment with the highest average weight comes with a significantly higher VSI than treatments with smaller average weights, even though all subsampled individuals used to determine VSI are of equal body weight across treatments. However, fillet yield has not been significantly different between treatments, thus this higher visceral discard does not necessarily impact total production in terms of fillet. This discarded fat consists of excess calories and omega-3s, a net resource loss. An area for further research is to optimize diets to decrease visceral fat (waste), while maintaining high fillet yield.

Meigs, Kampachi, Table 2

| Treatment | Average VSI (%) | Significance | Average fillet yield (%) | Significance |

|---|

Treatment | Average VSI (%) | Significance | Average fillet yield (%) | Significance |

|---|---|---|---|---|

| Control | 7.8 ± 0.9 | a | 61.7 ± 0.6 | a |

| PM no FO | 5.7 ± 0.6 | b | 60.9 ± 1.0 | a |

| PM+FO | 6.4 ± 0.7 | b | 61.2 ± 1.3 | a |

In regard to feed conversion ratio (FCR), results showed the experimental diets were slightly more efficient than the control, but not to a significant degree. Variation between tanks was very low, indicating consistent performance. This is particularly noteworthy because it suggests S. rivoliana can assimilate these terrestrial proteins and fats just as efficiently as their marine-sourced counterparts. It also suggests that if consumption of the experimental diets was the same as the Control, then there would have been no difference in growth rates.

Perspectives

This experiment was the final in a series of grow-out trials that has yielded a fishmeal and fish oil-free feed for Seriola that is cost-effective, and which demonstrates competitive growth rates and comparable FCRs. In a blind taste test between fish from the Control diet and the PMnoFO treatment, 62 percent of the participants preferred the fish fed the PMnoFO, while 19 percent preferred the Control, and 19 percent could not tell the difference between the two. This consumer feedback is a promising indicator that the flavor profile of the fish grown with zero fishmeal or fish oil is indiscernible, or possibly even preferred to that of the fish grown on a standard commercial diet high in fishmeal and fish oil.

The PFG poultry meal used in these diets costs 57 percent less than the current price of fishmeal at the time of this publication. U.S. poultry produced over 26 million metric tons (MT) live weight in 2019, yielding 19 million MT of edible product. Processing by-products could therefore easily supplant the approximately 0.5 million MT of fishmeal used globally in marine fish aquaculture (IFFO 2018). The canola, flax and Veramaris™ algae oil blend used here provides a matching DHA and omega-3:omega-6 ratio to fish oil. As the Veramaris™ production achieves economies of scale, such blends will price less than fish oil. Replacing wild-caught fishmeal and fish oil is now as much an economically prudent decision as it is an environmental imperative.

Ocean Era and other researchers have previously shown successful performance of marine fish on fishmeal free diets, but these examples were usually cost-prohibitive for commercial scaling. This is therefore the first instance of a fishmeal and fish oil-free diet being cost-effective, and still fulfilling the FCR requirements for commercial producers. Full grow-out has yet to be demonstrated, but this three-trial series has shown repeated success of the base formulation on kampachi from various cohorts at a range of sizes.

The fishmeal free diet (PM+FO) and the fishmeal and fish oil-free formulation (PMnoFO) tested here are ready for incorporation into commercial grow-out operations. Ideally, these formulations will be adapted to other marine fish diets. Our results demonstrate potential for a drastically reduced footprint for carnivorous finfish production, and this need not be limited to Seriola but could be extended to – and evaluated for – various other commercially important species of finfish.

To allow further development, all trial results and diet formulations are open source. They can be viewed at the F3 Feed Innovation Network website.

References available from corresponding author.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Helen Meigs, MAS

Ocean Era

Kailua-Kona, Hawaii USA -

Frederick Barrows, Ph.D.

Aquatic Feed Technologies

Bozeman, Montana USA -

Neil Anthony Sims, M.Sc.

Ocean Era

Kailua-Kona, Hawaii USA -

Kelly Alfrey, B.S.

F3 Future of Fish Feed

Tagged With

Related Posts

Aquafeeds

Aquaculture Exchange: Rick Barrows

After 14 years with the USDA’s Agricultural Research Service, Rick Barrows talks about the importance of finding ‘complete’ and commercially viable alternative sources of omega-3 fatty acids and continuing innovation in the aquafeed sector.

Aquafeeds

Alternative feed ingredient universe to convene at F3 meeting

What started out as a simple yet ambitious contest to drive innovation in the aquafeed sector has evolved into a fully global competition – and collaboration – amongst ingredient suppliers and feed manufacturers.

Aquafeeds

Montana firm putting barley on the alternative feed ingredient menu

Aquafeed manufacturers around the world seeking alternatives to fishmeal may soon be able to turn to an abundant and underutilized crop: barley.

Aquafeeds

Why I chose to judge the F3 challenge

In an opinion piece for the Advocate, the director of ocean sustainability science at the New England Aquarium talks about the F3 Challenge and what the first X Prize for aquaculture could do for the industry: drive innovation.