Production systems, utilization and research needs

Several non‐conventional proteins have gained interest as potential alternative protein sources for fish feeds. A number of earthworm species have been tested for fish feed production; some have nutritional content comparable to fishmeal and are within the recommended nutritional requirements of most fish. However, many of these worm species are not adaptable to a wide range of climates and excess handling, and most have resulted in depressed fish growth and poor feed utilization.

The red earthworm (Eisenia fetida) – also known as redworm, brandling worm, panfish worm, trout worm, tiger worm, red wiggler worm and other common names – is a species of earthworm adapted to live and thrive in decaying organic material like rotting vegetation, compost and manure. Studies have shown that the red earthworm has adequate levels of protein, essential amino acids and lipids similar to those found in fishmeal and are aligned with the nutritional requirements of many fish species. Other studies have recommended E. fetida meal to replace conventional fish feed protein sources without compromising the growth performance and reproduction of the cultured fish species.

Red earthworms have excellent growth rates, are adaptable to different organic materials with the ability to convert biodegradable matter up to five-fold. Compared to most earthworm species, they have a relatively high reproduction rate (i.e. three hatchlings per egg) with a short maturation cycle, and low mortality compared to most earthworm species. Worms can survive in extreme conditions such as low temperatures, toxic and saline environments. Also, it is a surface dweller, which facilitates its harvesting at a lower production cost, as it requires less human labor to feed and continuously turn its substrates to promote aeration. Worms can be efficiently contained in and raised in great quantities within several levels of production units using simple vermicomposting (composting process with various species of worms in a mixture of decomposing, waste and bedding materials) techniques.

Because of its biological and economic attributes, several published studies have reviewed the potential of red earthworms as a replacement for fishmeal. This article summarizes the production systems and utilization sections of the original publication, which comprehensively reviewed the biological and biochemical composition, production and processing methods as critical aspects for sustainable production and utilization of the red earthworm in the fish feed industry. For detailed information on reproduction biology of E. fetida; its culture substrates; production systems; processing techniques; and its biochemical composition and utilization in fish feed formulation, consult the original publication.

Production systems

Vermicomposting uses the mutual action of earthworms and microorganisms to bio‐transform organic matter into safe and stable compounds. Therefore, earthworms are usually a byproduct of vermicomposting alongside vermicast (solid phase) and vermiliquid (liquid phase) fertilizers. Producing earthworms as ingredients for fish feeds depends on the intensity of the aquaculture system. In intensive aquaculture systems, aquatic organisms are usually stocked at high densities and depend on high quality and complete feeds, and thus earthworms must be mass-produced to meet feed demand. In Japan, for example, there are more than 3,000 vermicomposting plants that provide earthworm for processing fish feed for intensive aquaculture systems such as for eel (Anguilla japonica) farming.

In contrast, in semi‐intensive aquaculture, aquafeeds often supplement the natural production in ponds, and earthworms are usually produced depending on the primary production of culture systems. For example, researchers have demonstrated that red earthworm meal can supplement natural feeds at a 50 percent replacement level of fishmeal in Indian carp semi‐intensive farming. In addition, vermiculture is utilized to supply organic fertilizer for improved primary production in semi‐intensive farming. Several studies have shown that the vermicast fertilizer has about the same impact on primary productivity in semi‐intensive fish ponds as livestock manure. And the vermiliquid can also be utilized as an ingredient in formulating feeds for tilapia.

Large‐scale earthworm production

Industrial/commercial vermicomposting is done principally for the management of municipal, agricultural and industrial bio‐solids. Since the inception of vermicomposting in Canada in 1970, various innovative production systems have been established in many countries (USA, Italy, Australia, Cuba, Philippines, India and others). Commercial vermicomposting is broadly categorized into windrow and flow‐through systems.

Windrow systems are a simple technology commonly used for composting crop waste materials for fertilizer production, and it has been modified for large scale/industrial vermicomposting in several countries. The biodegradable materials are placed either vertically or horizontally up to one meter high, and then inoculated with earthworms. The beddings are periodically watered to keep the bedding moist, and depending on the weather, the windrows can be kept open or covered. It is advisable to use a concrete floor for easier collection of the vermiliquid. Mass harvesting of cast‐free earthworms from this system is done using commercially available, mechanical, centrifugal harvesters.

In the flow‐through (or open bed) system, the earthworms are cultured indoor typically using large, rectangular beds. In this vermicomposting system, cast‐free earthworms are normally harvested by slightly starving the earthworms for at least one week, then adding new food or bait (preferably cattle manure mixed with nettle, valerian or flaxseed) at the surface to attract the worms to move upwards.

Small‐scale earthworm production

Small‐scale vermiculture is commonly done using plastic bins and wooden boxes layered with polyethylene. Earthworms are normally fed on locally available plant biomass, kitchen and market wastes, biogas slurry, urine free cow dung, wheat straw, leaf litter and saw dust that are known to be high in organic matter. Harvesting earthworms can be done by pouring the content from culture bins on a plastic sheet and manually collecting the animals.

Small‐scale earthworm production systems have long been used to improve fish yields in semi‐intensive farming systems. For example, small‐scale vermicomposting can improve common carp production yields by 75 percent in semi‐intensive aquaculture system in northern Vietnam. And in India, integrated vermiculture/fish culture system provide both earthworm biomass and vermicast as organic fertilizer in catfish semi‐intensive ponds.

Utilization in aquafeeds

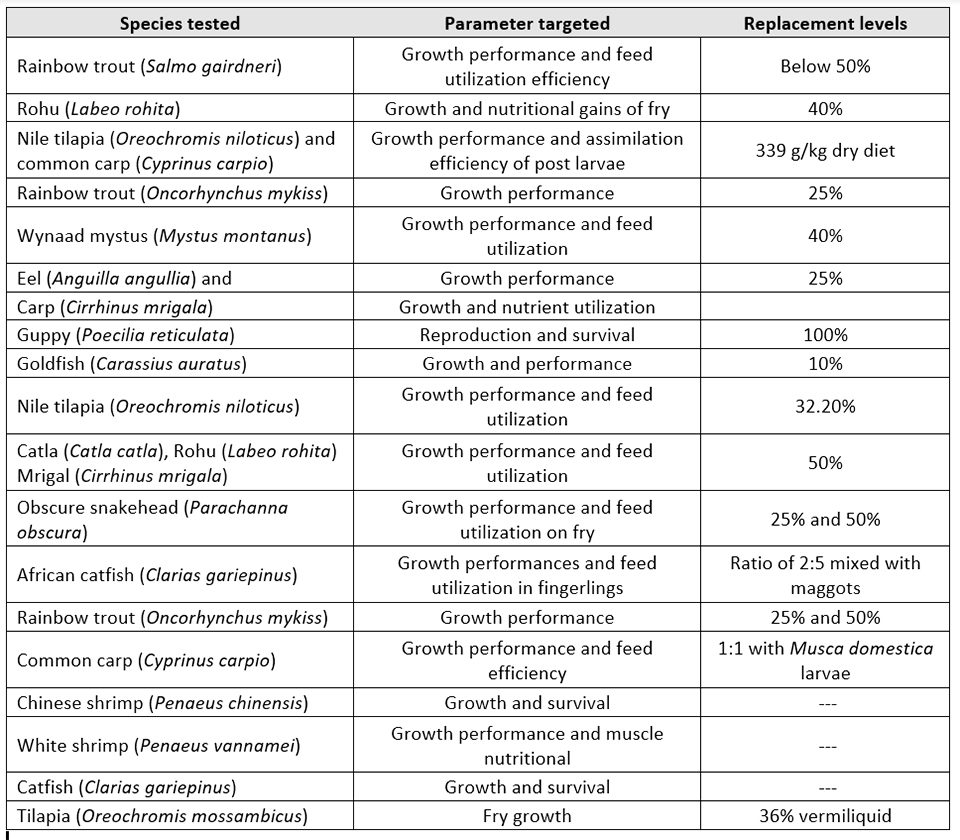

Many studies have reported the efficacy of red earthworms (alone or in combination with other ingredients) in promoting fish growth performance, increasing reproduction, enhancing feed digestibility, reduced stress, improved survival, lower feed conversions and better feed utilization and assimilation efficiency (Table 1).

Most of these studies showed that red earthworm meal can replace fishmeal up to a 50 percent inclusion levels, but some reported reduced fish growth with inclusion levels above 25 percent, mentioning indigestible chitin and foul‐smelling coelom fluid that reduce digestibility and palatability. For example, research showed that common carp and Nile tilapia had lower specific growth rates of 2 and 1.3 grams per day, respectively, when fed on diets with red earthworm meal, compared to 2.2 and 2 grams per day obtained when fed on diets with fishmeal.

Research needs

Improved harvesting techniques are needed, to better recover the worms from the production systems. The sensitivity of the earthworms to light could be one approach, and this could also be used to transfer the animals from old to new substrates during culture. Additionally, because the chitin (a polysaccharide component of the exoskeleton) levels in the worms is directly proportional to their age, improved harvesting system should target the collection of medium aged worms only. Also needed is a nutritionally complete and soft textured culture substrate, which would reduce the development of the indigestible chitin in the worm’s exoskeleton. This will further reduce unnecessary movement and burrowing in search of food materials.

Perspectives

There is a significant body of information on the biology, production and processing methods of red earthworms – reviewed in this study – relevant to the commercial mass production of nutritionally complete E. fetida meal for fish feed formulas. In addition, together with other vermicomposting by‐products like vermicast and vermiliquid, local production of red earthworms can benefit small‐scale fish farmers who often have under‐utilized organic wastes.

Red earthworm meal can efficiently and sustainably replace a number of conventional animal and plant protein sources while supporting fish growth. More research is needed to achieve the commercial production of red earthworms meal to formulate low‐cost, practical and environmentally-friendly, nutritional feeds for sustainable farming of various fish species.

References available in original publication.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Dr. Sonnia Nzilani Musyoka

Department of Fisheries Management and Aquaculture Technology

South Eastern Kenya University

Nairobi, Kenya -

Dr. David Mbeva Liti

Department of Biological Sciences

University of Eldoret

Eldoret, Kenya -

Dr. Erick Ogello

Department of Fisheries and Natural Resources

Maseno University

Maseno, Kenya -

Dr. Herwig Waidbacher

Department of Water, Atmosphere and Environment

University of Natural Resources and Life Sciences

Vienna, Austria

Tagged With

Related Posts

Health & Welfare

Malaysian mahseer: New candidate for Asian aquaculture?

There is much interest in the biology and artificial propagation of the Malaysian mahseer, both for conservation and aquaculture production.

Aquafeeds

Polychaete worms reduce waste, provide food in aquaculture

Adaptable and diverse, polychaetes can adapt their feeding behaviors to environmental conditions. Nereis diversicolor, a marine polychaete that can tolerate wide temperature and salinity ranges, is a good candidate for RAS enhancement.

Responsibility

Polychaete-assisted sand filters show potential in treating effluents

A practical way to treat mariculture effluents combines the physical attributes of a sand filter and the biological properties of hungry marine sand worms.

Aquafeeds

Larvae lunch, anyone? Insect-based feeds soon on aquafeed menu

This July, European Commission regulations allowing insect-based feed will be amended, and insect-farming companies like Agriprotein and Ynsect are gearing up for expansion in the EU.