Vaccination can prevent outbreaks where disease occurs with predictable frequency

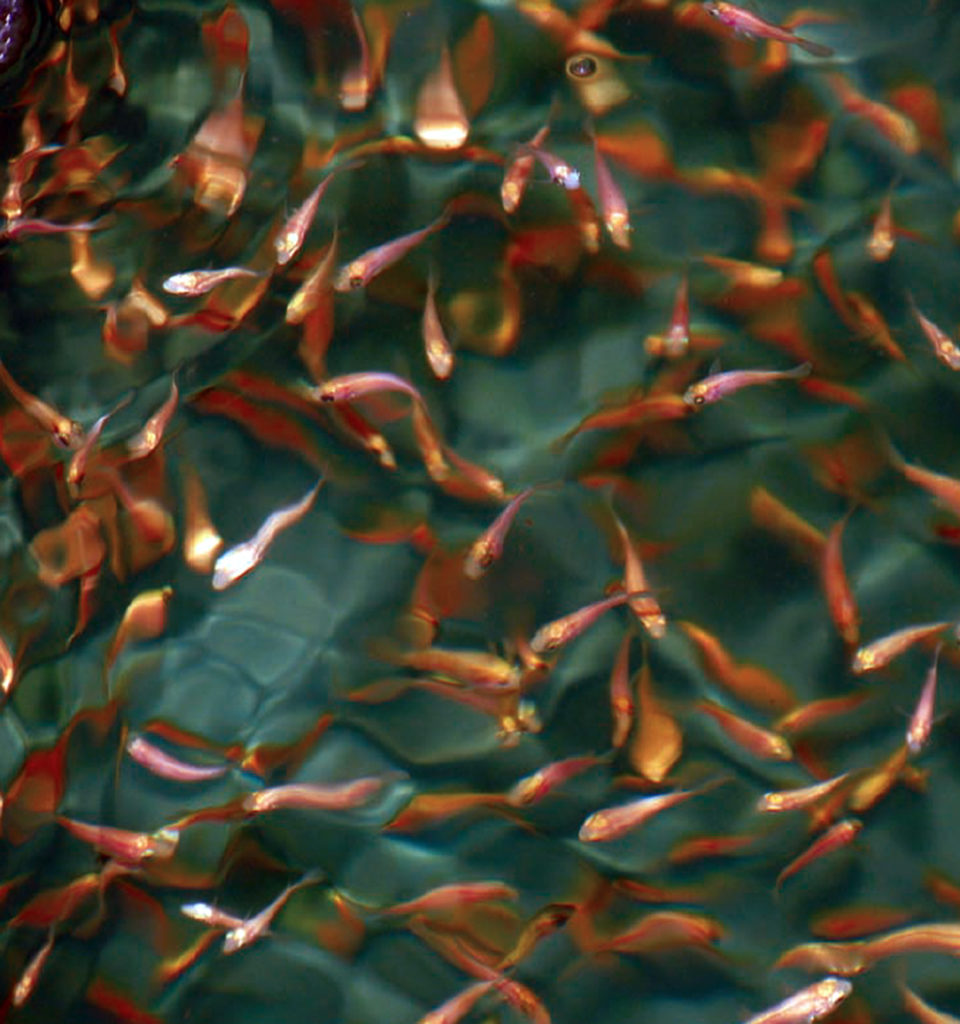

The Nile tilapia is one of most widely cultured fish species in the world because of its good feed conversion, fast growth, high reproduction, and ease of production. But, in contrast to what was believed during the early years of culture intensification, this fish is highly susceptible to various diseases that affect producer profits and consumer product costs.

The demands of consumers and environmental and government groups for wholesome tilapia products and an environment free of potentially harmful drugs and chemicals in aquaculture continue to grow. The tilapia industry can meet these challenges through better health management practices that include the use of vaccines to prevent diseases and increase economic predictability and profitability.

Major tilapia diseases

Among the major bacterial pathogens of Nile tilapia are Streptococcus iniae, S. agalactiae, Aeromonas hydrophila, Edwardsiella tarda, and Flavobacterium columnare. The major parasite pathogen is Ichthyophthirius multifiliis.

The Gram-positive bacteria Streptococcus iniae and S. agalactiae are highly virulent to cultured tilapia and cause disease in a wide variety of fish species in more than 23 countries worldwide. These streptococcal pathogens are responsible for significant morbidity, mortality, and economic losses of more than U.S. $150 million annually.

Infections of S. iniae and S. agalactiae can occur singularly and concurrently in Nile tilapia. Both pathogens can rapidly spread from fish to fish year-round, especially in warm climates. Stressful conditions or poor nutrition favor streptococcal infection.

A. hydrophila infection can occur in Nile tilapia in conjunction with these streptococcal pathogens and others. F. columnare infection has also been reported in fingerlings and adult Nile tilapia. High morbidity and mortality have been associated with this skin and systemic disease. Nile tilapia are also susceptible to E. tarda that results in serious disease problems in stressed or malnourished fish.

Vaccination: ‘insurance’ and biosecurity tool

Vaccination can be thought of as an insurance policy against specific disease outbreaks that can cause serious economic damage. At production sites where a specific disease occurs with a predictable frequency, vaccination can prevent the outbreaks. Disease risk, vaccine efficacy, vaccination cost and expected market losses are among the factors that need to be evaluated before vaccination protocols can be implemented.

Vaccination is also a biosecurity tool to prevent the spread of a pathogen from one location to others. Streptococcal pathogens are an excellent example of rapidly spreading and emergent diseases that can be prevented by vaccination.

Vaccines

Fish vaccines are regulated biologics that are licensed for manufacture, use, and distribution in most countries. These regulations ensure that the licensed vaccines are safe, pure and efficacious. The efficacy of a vaccine is most often expressed as the “relative percent survival.”

Vaccines can be produced against a single pathogen (monovalent) or multiple pathogens (polyvalent). The efficacy of each component of a polyvalent vaccine must be shown to not interfere with that of other components in vaccinated fish. Autogenous vaccines can be produced for use at a single farm if the vaccine master culture is obtained from that farm. Such vaccines can also be licensed for use on multiple farms, if the vaccine is universally efficacious and fully licensed.

Killed bacterin and live, avirulent vaccines are the most common types used in aquaculture. Both have advantages and disadvantages. While safety is an advantage for bacterins, their short several-month duration of protection is a disadvantage. Avirulent vaccines offer years-long duration but a lower level of safety.

Studies led to the development of safe and effective S. iniae and S. agalactiae vaccines applied by both immersion and injection. Ongoing studies are now focused on the development of a combined S. iniae and S. agalactiae vaccine that can be given by immersion of fry or juvenile Nile tilapia. A licensed avirulent F. columnare vaccine is administered by immersion, while an F. columnare bacterin is administered by injection.

Technology transfer

The development, manufacture, licensing, distribution, and use of a vaccine require partnerships between researchers, manufacturers, regulatory licensing agencies, stakeholders and aquaculturists. Stakeholder meetings, workshops and questionnaires spur communication between partners to establish the severity ranking of diseases and the vaccines needed to prevent them.

In the United States, technology transfer coordinators work to establish a cooperative research and development agreement that defines the goals, responsibilities, and time line of vaccine development between the researchers and manufacturer. The roles of the researchers and manufacturer are to jointly develop a safe and cost-effective vaccine that can be used for mass vaccination of tilapia against a particular pathogen.

The biologic manufacturer develops an outline of production and protocols for testing the safety, purity, and efficacy of the developed vaccine prior to the actual testing. The manufacturer must meet all U.S. Department of Agriculture, Animal and Plant Health Inspection Service (APHIS), and Center for Veterinary Biologics regulations and directives, and submit its data to APHIS or a similar agency for licensing approval.

When the cost benefit of manufacturing and distribution can not be met, governmental agencies may need to provide supplemental support for vaccines needed as preventative tools against particular pathogens. This support can be in the form of small business grants or other types of grants from governmental agencies and

fish producer groups.

(Editor’s Note: This article was originally published in the May/June 2007 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Phillip Klesius, Ph.D.

U.S. Department of Agriculture

Agriculture Research Service

Aquatic Animal Health Research Laboratory

990 Wire Road

Auburn, Alabama 36830 USA -

Craig Shoemaker, Ph.D.

U.S. Department of Agriculture

Agriculture Research Service

Aquatic Animal Health Research Laboratory

990 Wire Road

Auburn, Alabama 36830 USA -

Joyce Evans, Ph.D.

USDA Agriculture Research Service

Aquatic Animal Health Research Laboratory

Chestertown, Maryland, USA

Tagged With

Related Posts

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Health & Welfare

A look at tilapia aquaculture in Ghana

Aquaculture in Ghana has overcome its historic fits and starts and is helping to narrow the gap between domestic seafood production and consumption. Production is based on Nile tilapia.

Responsibility

‘Model’ tilapia venture shows mettle in Mozambique

On the shores of Lake Cahora Bassa, Chicoa Fish Farm hopes to create a ripple effect to improve fish supply and quality of life for an impoverished region.

Aquafeeds

A look at India’s fish feed industry

India's fish-farming industry makes limited use of modern feeds, providing potential for the feed sector to grow. Commercial feeds are predominantly used for pangasius farming, followed by a rising popularity in carp culture.