Solids capture and biofiltration in a single unit

Whether it is the need to expand beyond the flow capacity of an artesian spring, conforming to new effluent regulations, heating costs, or production quality, water recirculation/ reuse is likely to be an element in virtually all aquaculture production facilities of the future. Water recirculation will first creep and then surge forward as a production tool. The ability to recirculate water should be viewed as a tool that can be integrated into existing approaches, enhancing profitability.

Currently, only tradition prevents widespread use in support of broodstock management and fingerling production programs for established industries as diverse as catfish and trout. Economic factors still limit grow-out applications, but it should be recognized that it is largely recirculating technologies battling for market share in the live tilapia markets of North America. Any new upcoming effluent regulations (please see http://ag.ansc.purdue.edu/ aquanic/jsa/effluents/index.html) will only make recirculating options more attractive to the producers who are ready to adopt the most cost effective production technologies.

Water reuse implies the reconditioning of the water. There are five major processes that must be addressed in any recirculating application. These are aeration, circulation, solids capture, biofiltration, and carbon dioxide stripping. These major processes must be employed much in the order they are listed as you increase the degree of water reuse. Most modern raceway systems employ sophisticated aeration systems, but solids capture is mostly used simply to improve effluent quality. Ammonia levels must be addressed as soon as the water is recirculated. The use of a biofilter is a major step, mostly in thinking, as the objectives of water treatment change. Now the water is being treated for the benefit of the fish. The realm of recirculation has clearly been entered.

Floating bead bioclarifiers were originally developed to overcome the shortcomings of sand filters. The caking problems that plague sand filters result from their natural tendency to support luxurious bacterial growths. Their application as a solids capture device in aquaculture is usually limited to the cleanest applications, usually by supporting it with ozone. Floating plastic beads can be easily separated from captured solids or biofloc. This is accomplished with very little water loss; therefore, they can be used in systems that reuse water for weeks, even months.

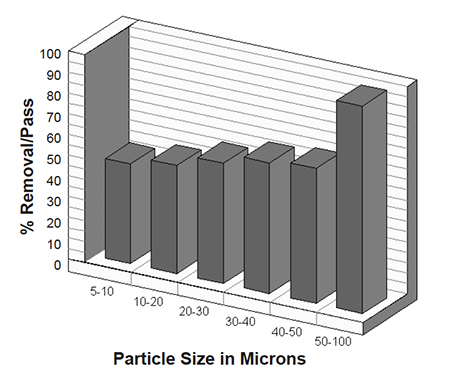

Floating bead filters are excellent solids capture devices. They capture solids about as well as a sand filter with the same media diameter. Fig. 1 illustrates the capture removal profile for particle sizes down to 6 microns for a filter filled with 1/8-inch polyethylene beads. In comparison, settling basins are considered ineffective as removal device below 100 microns (1/3 the diameter of a human hair), and most micro-screens are effective only to the 40 to 60 micron range.

At a single pass removal efficiency of 40 percent, the capture rate of the fine solids exceeds their rate of generation since the water will normally pass through the filter 20 to 30 times per day. When properly operated, bead filters produce clear waters. Their ability to remove fine particles gives them a competitive advantage in high reuse applications where long term accumulations of fine solids leads to problems with turbidity and biofiltration. Bead filters compete very well as clarifiers, and are used often in combination with fluidized beds to tackle the solids capture and biofiltration needs.

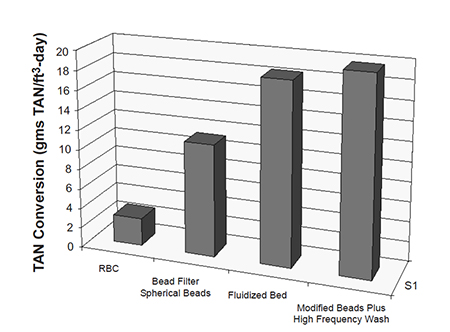

However, bead filters are also very good biofilters. With management, the annoying tendency to grow bacteria can be turned to advantage. The concept is called bioclarification: solids capture and biofiltration in a single unit. While the unit is capturing solids, the biofilm growth on the surface of each bead can be managed to encourage nitrification and control ammonia levels. Fig. 2 illustrates the nitrification capacities of well-known biofilters. Older bead filter units were about half as effective as fluidized beds, the newer units that employ improved beads are very competitive, even while they are also capturing solids.

Recirculating costs may be reduced and system stability improved if treatment steps are consolidated using as few treatment components as possible. A recently published scientific paper (Malone and Beecher, 2000) summarizes design criteria for three recirculating classes: broodstock, fingerling and grow-out. This paper provides scientific arguments in support of bioclarification strategy and presents detailed sizing recommendations for the pumps (circulation), aeration (aeration/ carbon dioxide stripping) and bead filters (solids capture/biofiltration) using normal spherical beads (Table 1). These sizing criteria have been used in the commercial sector for a number of years. They include reasonable safety factors and are used for design or economic evaluations.

Ongoing research is developing of criteria for use of bead filters (solids capture and biofiltration) in combination with airlift pumps (circulation/aeration/ carbon dioxide stripping). Air needed for gas exchange can also be used to recirculate the water. Elimination of water pumps lowers capital investments and reduces the energy costs. The importance of media shape has been fully recognized, and the newer units are raising the nitrification capacities (as illustrated in Fig. 2) despite the need to operate filters at extremely low head losses (<18 inches).

Malone, Interim guidelines for the design of recirculating systems, Table 1

| System Characteristics Sizing Criterion | System Characteristics Broodstock Systems | System Characteristics Ornamental/Fingerlings | System Characteristics Grow-out Applications |

|---|

System Characteristics Sizing Criterion | System Characteristics Broodstock Systems | System Characteristics Ornamental/Fingerlings | System Characteristics Grow-out Applications |

|---|---|---|---|

| System volume (gal water/lb feed-day) | 800 | 400 | 200 |

| Bead volume (ft3 beads/lb feed-day) | 4.0 | 2.0 | 1.0 |

| Circulation rate (gal/lb feed-day) | 25.0 | 10.0 | 6.0 |

| Air for airstones (scfh/lb feed-day) | 361 | 361 | 180 |

| NaHCO3 dose (lb/lb feed-day) | 0.24 | 0.24 | .24 |

| Water replacement (gal/lb feed-day) | 72.7 | 24.7 | 8.2 |

Conclusion

Recirculation is going to play an increasingly important role in production systems. Bead filters can contribute as a solids capture device in support of a biofilter, or as bioclarifiers performing both functions. Sizing criteria are presented even as the technology is being refined and improved. The scientific work has been ongoing for over a decade and commercial adoption is rapidly becoming the proof of utility.

Reference Malone, R.F. and L.E. Beecher. 2000. Use of Floating Bead Filters to Recondition Recirculating Waters in Warmwater Aquaculture Production Systems. Journal of Aquacultural Engineering, 22:57-73.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Ron Malone, Ph. D.

Department of Civil and Environmental Engineering

Louisiana State University

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Intelligence

Biofilters: Choosing your substrate

Heterotrophic and autotrophic bacterial communities supported within a biofilter naturally process organic wastes and provide biologically stable water.

Responsibility

Biofilter start-up problems? Just add sugar!

One way to jump start biofilter operation is by adding sugar, which can provide sufficient organic carbon to neutralize the ammonia-nitrogen produced.

Responsibility

Geotextile bags enhance effluent management in demo aquaculture system

One promising new technology for dewatering aquaculture solid waste is the use of geotextile bags: porous, sealed tubular containers constructed of high-strength, woven polyethylene material.