Rotifers are a preferred food source for larval fish. This study tested the growth and production of rotifers raised in conical tanks and fed microalgae paste. The primary food of most larval fish species is zooplankton. Rotifers are a dominant zooplankton that are a preferred prey for larval fish and one of the live feeds most often used by fish culturists.

Brachionus plicatilis, a brackish water rotifer species, is well suited for mass culture because it is prolific and can tolerate a wide variety of environmental conditions. Its mass production is an indispensable source of live food for the early stages of many commercially cultivated fishes.

Mass production of this rotifer can be based on different alimentary sources, including various species of live and dried microalgae, and yeast and bacteria concentrates. The authors investigated the effect of microalgae paste on rotifer growth and production in a 21-day trial in a greenhouse laboratory.

Culture system

Rotifers were cultured in translucent, 60-liter conical polyethylene tanks with culture volume maintained at 45 liters. The water temperature in the tanks was kept above 25 degrees-C by suspending a 100-watt immersion heater in each tank.

A sponge filter was also suspended in each tank to remove particulate matter (i.e., rotifer casings, flocculated algal particles, fecal matter). Culture volume was drained from the tanks through PVC ball valves connected to the bottoms of the tanks.

Feeding and culture

Four tanks were utilized for culturing rotifers using a commercially available Nannochloropsis sp. algal paste for feed. The algal feed concentration provided was 75,000 algal cells per rotifer per day based on the manufacturer’s concentration of 65 billion cells per millileter of paste.

The volume of algal paste in the feed solution varied daily based on the after-harvest rotifer count. The required amount of paste was diluted with seawater to a volume of 2.4 liters. The dilution was kept in plastic containers inside an electric cooler to prevent it from putrefying. A peristaltic pump connected to a timer delivered 100 ml of the feed solution every hour to the culture unit.

During the 21-day culture period, the rotifer population in each tank was maintained at 500-1500 rotifers per millileter. Daily counts in each tank were done with a 1-ml counting cell in triplicate by counting a 1-ml sample diluted 10:1 in saltwater. A volume of 15 liters was harvested when the rotifer count rose above 1,500 rotifers per millileter and replaced with fresh 25-ppt artificial saltwater circulated through a 1-μ cartridge filter and UV sterilizer.

Water quality variables were measured daily. Dissolved oxygen was above 4.0 milligrams per liter, pH was steady at 8.0 and salinity ranged 23 to 28 ppt. Approximately 200 to 300 ml of settled wastes were purged from the culture tanks daily via the drain valves.

Results

The four tanks were at the designated 1,500 rotifers per ml harvest levels 64 to 73 percent of the time. Based on the rotifers harvested, the average salt and algal paste cost ranged $0.23 to $0.26 per million rotifers harvested.

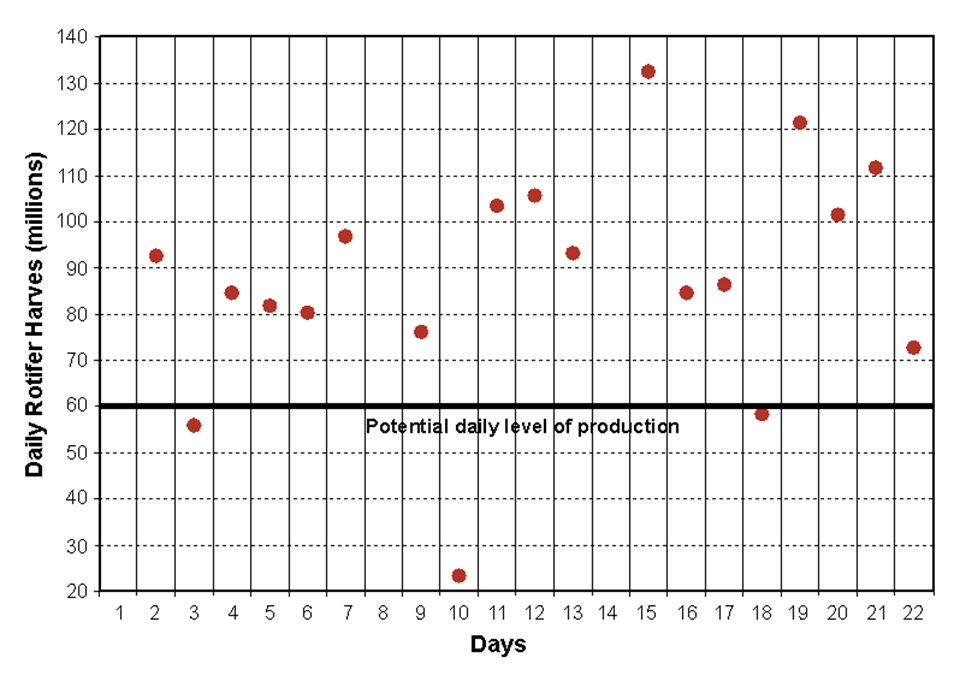

Except for three days when no rotifers were harvested, daily rotifer harvest ranged 20 to 135 million rotifers (Fig. 1), with average production of about 75 million rotifers. Being a live production system, a 20 percent safety factor was incorporated to give a safe level of system production for feeding larval fish at approximately 60 million rotifers per day.

Conclusion

Simple and inexpensive systems that use algal paste as a food source appear appropriate for use as basic units for the mass production of rotifers in commercial fish hatcheries. Such systems can allow the year-round production of many fish species.

(Editor’s Note: This article was originally published in the August 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Timothy J. Pfeiffer, Ph.D.

U.S. Department of Agriculture Agricultural Research Service

Aquaculture Systems Research Unit

1200 North University Drive

Pine Bluff, Arkansas 71601 USA[117,100,101,46,120,101,97,117,64,114,101,102,102,105,101,102,112,116]

-

Gerald M. Ludwig, Ph.D.

USDA/ARS

H.K. Dupree Stuttgart National Aquaculture Center

Stuttgart, Arkansas, USA

Tagged With

Related Posts

Responsibility

Farming algal fuel: Economics challenge process potential

Algae offer advantages over terrestrial plants for biofuel production: short generation cycles and fast population growth. Algal fuel production would spare corn and soybeans for consumption as food for humans.

Aquafeeds

Formulated diets: Replacement for live food in marine fish larvae

Creating formulated diets for fish larvae is difficult because estimating nutritional requirements cannot be done using traditional nutritional approaches.

Intelligence

Intensive fish farming in Italy

Intensive production equipment and management techniques allow the Nuova Azzurro Fish Farm in Italy to raise about 50 metric tons of sea bass per raceway per year.

Health & Welfare

Rotifer enrichment: Concept simplifies larval fish feeding

In trials, a culture diet that naturally enhances rotifers and eliminates the need for enrichment was tested. Skretting feed specialists found similar growth and reproduction figures were registered with a conventional rotifer enrichment diet and a standalone diet for a period of nine weeks.