Ultrasound highly effective in reducing bacterial biofilm formation

Channel catfish production relies on timely sales of fish, but sales schedules can be hampered by the occurrence of off-flavors and fish mortality from disease. Efforts to control off-flavor have used chemical treatments such as diuron, sodium chloride, hydrogen peroxide, titanium dioxide and copper. These are effective but can lead to increases in chemically resistant pathogens in ponds requiring repeated applications that can be labor-intensive and increase production cost. Diseases can result from the presence of bacteria, viruses and fungi in ponds.

An alternative to chemical treatments is the use of ultrasound. Previous applications of this technology have included cooling tank treatment; laboratory-based control of cyanobacteria, diatoms and dinoflagellates; and inactivation of (Cryptosporidium) cysts.

Most of this previous work used single-frequency equipment. Several commercial versions of ultrasound equipment have been manufactured, including a system that emits 16 different frequencies. The authors recently evaluated the use of ultrasound equipment in channel catfish production systems.

Laboratory studies

An initial laboratory study evaluated the effect of ultrasound on catfish feeding and weight gain. Catfish fingerlings stocked at 13 fish/tank were acclimated to four control tanks and four tanks that received ultrasound treatments.

Initially, ultrasound was run continuously. The continuous operation caused fish not to feed, but stopping the ultrasound equipment during feeding resulted in no significant difference in catfish feed consumption or weight gain. The authors therefore modified protocols for this and further lab and field tests so the ultrasound equipment was turned off during a four-hour period surrounding feeding time.

Another laboratory study was conducted to assess ultrasound impacts on bacterial populations in aquariums. Small bacterial inocula were added to well water in eight tanks. Four tanks were then exposed to ultrasound treatment, and four tanks served as controls.

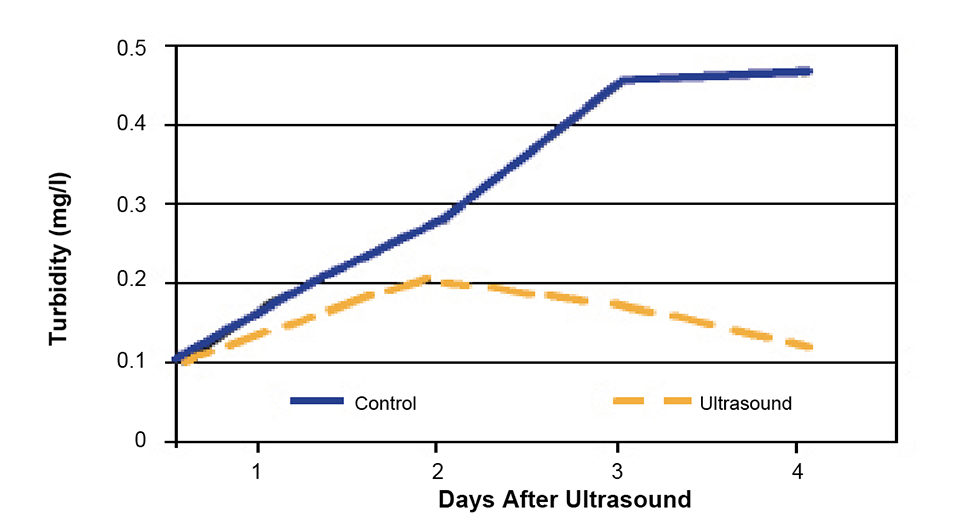

Daily samples were collected for bacterial counts and turbidity. Within three days, turbidity in tanks was decreased by 60 percent (Fig. 1). Bacterial cell counts using acridine orange direct counts and bacterial plating were significantly lower in the tanks with the ultrasound treatment compared to the counts in control tanks. These results suggested that use of ultrasound could reduce pathogenic bacteria in ponds to levels below those causing fish mortalities.

A further laboratory experiment assessed if ultrasound caused greater off-flavor diffusion from water to air. Eight tanks were dosed with 1-ppm 2-methylisoborneol, and four were treated with continuous ultrasound. Samples were collected daily for off-flavor and analyzed using gas chromatography-mass spectrometry. Tanks with ultrasound treatment had significantly (P = 0.09) lowered off-flavor levels.

Field study

A field study was initiated in 0.47-ha production ponds to assess the impacts of ultrasound on off-flavor and algal biomass. Ponds were stocked with channel catfish fingerlings and operated as grow-out ponds according to industry standards. Pond conditions were matched in terms of algal density and composition in two control ponds and two ponds treated with ultrasound. Two ultrasound devices were placed in ponds pointing along the long pond axes. The ultrasound equipment was run from 11 a.m. to 6 a.m. continuously, with feeding during the off period.

A dense bloom of the cyanobacterium (Microcystis c.f. ichthyoblabe) Kützing was present in two of the ponds. While dominant in two other ponds, the bacterium was 70 percent lower in overall biomass. Samples were collected weekly from ponds for algal biomass and off-flavor analyses.

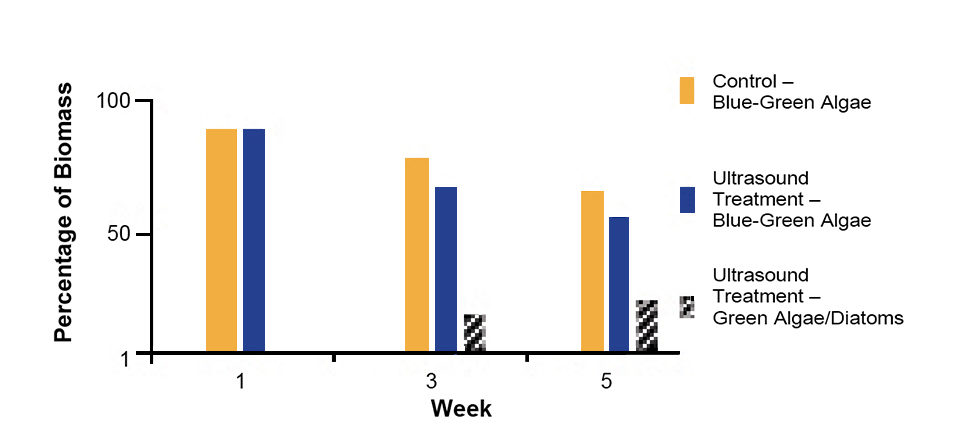

Total algal biomass decreased by about 48 percent during the four-week study. Algal composition in the ponds treated with ultrasound had an increased abundance of more desirable forms, particularly diatoms and green algae, relative to the control ponds (Fig. 2). Off-flavor concentration was decreased to a lesser degree.

Applications

It is fairly well established from the literature that ultrasound is highly effective in reducing bacterial biofilm formation. From these studies, it was clear that ultrasound can be used to treat free-floating bacteria and reduce these populations. It was also clear that cyanobacteria such as Microcystis are specifically targeted by ultrasound treatment. The equipment is less effective on cyanobacteria that do not contain gas vacuoles.

Equipment costs are around U.S. $3,500 per pond-size unit. As ultrasound equipment operates on either 110 or 220 voltage, advance planning for these voltages saves on retrofitting ponds.

Ultrasound equipment would be extremely useful for treating hatchery water to reduce planktonic microbes during embryo and swim-up fry development. Microcystis species are producers of bioactive compounds, including toxins that can cause losses in 10-25 percent of grow-out ponds. The presence of off-flavor in fish fillets further decreases revenue.

(Editor’s Note: This article was originally published in the July/August 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Paul V. Zimba, Ph.D.

USDA-ARS

Catfish Genetics Research Unit

P.O. Box 38

Stoneville, Mississippi 38776 USA -

Casey C. Grimm

Southern Regional Research Center

New Orleans, Louisiana, USA

Tagged With

Related Posts

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.

Health & Welfare

Amino acid supplementation reduces protein levels in pangasius diets

Trials show that supplementation with amino acids could reduce protein levels from a typical 28 percent to 23 percent in pangasius diets.

Health & Welfare

Near-infrared spectrometers determine stage maturity in channel catfish

This study evaluated the feasibility of a portable, hand-held micro near-infrared spectrometer to objectively determine the stage of maturity in channel catfish. Such a rapid, non-invasive method to stage fish maturity in hatcheries would improve the efficiency of hatchery production.