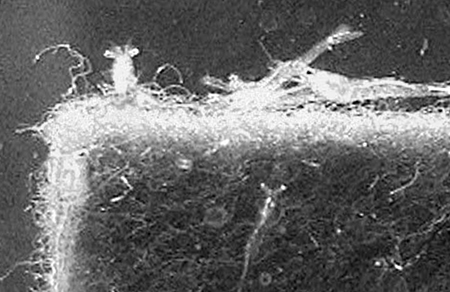

Growth surfaces can be initially seeded to insure optimum natural feed type and availability of feed

Shrimp undergoing metamorphosis from mysis to postlarvae develop a strong affinity for benthic surfaces. In fact, shrimp larviculture can be separated into two distinct phases based on shrimp behavior and feed preferences. Phase I is that portion of the larviculture cycle from nauplii through postlarvae (PL1), where feeding behavior is exclusively planktonic. Phase II is from metamorphosed postlarvae (PL2) to harvest.

Once shrimp transform to PL2, most of their feeding behavior is based on an orientation to a benthic surface. Recent research indicates that this change, from planktonic to benthic behavior, coincides with the development of numerous enzyme systems directed towards periphyton grazing and utilization of detritus as a feed resource.

Recognition of this behavior has led hatchery operators to experiment with the addition of natural and/or synthetic, high-surface-area substrates to the culture environment. Some of the earliest attempts to enhance benthic productivity involved the pre-cultivation of benthic diatoms on the tank walls of a second-stage larviculture tank that received PLs from the first-stage tanks. Practitioners of this strategy, also known as “sliming,” reported excellent survivals and improved animal health. The derived benefit was limited, however, due to the very modest amount of surface area available on the tank surfaces.

Synthetic substrates

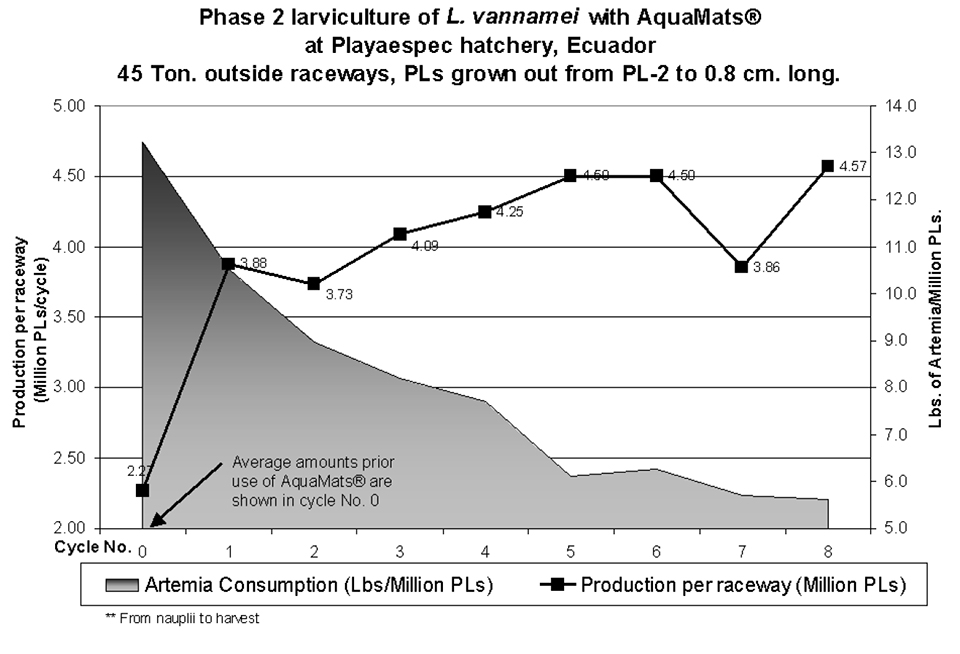

Recent advances in this technology have focused on the use of commercially available, reusable synthetic substrates that extend benthic surfaces throughout the water column. Using standard mass culture techniques for benthic diatoms, these growth surfaces can be initially seeded to insure optimum natural feed type and significantly increased availability of feed. Following are results of various studies in Ecuador using AquaMats® substrates, a product line produced in the U.S. using Ultraweave™ Technology.

In trials conducted in several large commercial hatcheries, substrates were matured in outdoor phase II larviculture raceways using a combination of filtered seawater and stock algae cultures of benthic diatoms (Navicula sp. and Amphora sp.). The substrates were matured for seven to 10 days prior to the transfer of the postlarvae (PL2) from the indoor larviculture tanks to the outdoor, second stage larviculture raceways.

The pre-growth medium consisted of seawater filtered to 300 microns and stock cultures of Amphora coffaeformis and Navicula inserta. This inoculum provided a richly diverse community, with over 140 species of algae, bacteria, and zooplankton that formed a rich aquatic pasture on the substrate surfaces. This allowed the shrimp postlarvae to find and utilize the ideal size and form of feed throughout its development.

Over a period of six consecutive hatchery cycles, the following was observed in the tanks equipped with substrates:

- Average artemia consumption was gradually reduced from 13.2 pounds per million postlarvae to 5.6 pounds per million PLs.

- Average stocking density was increased from 62 to 109 PL2 per liter.

- Average survival increased from 82 to 91 percent.

- Average time to go from PL2to PL10 gill brachiation development was reduced by two days.

At another Ecuador hatchery, the effect of substrate technology on zero-salinity stress test performance was studied. At PL8, 100 percent of the animals grown in the presence of substrates passed the test, versus only 85 percent for the control group. The use of substrate technology has also been used to reduce size disparity in shrimp postlarvae. In a study conducted at a Panamanian facility, PL2 were grown out to PL12 in raceways. In the raceways equipped with substrates, the average survival increased from 65 to 93 percent, the average PL weight increased from 2.8 milligrams per PL to 7.0 milligrams per PL, and the disparity in size decreased by over 50 percent.

Conclusion

With the recent scarcity of, and subsequent price increases for, high-quality artemia cysts, alternative larval feed resources need to be considered. The use of high-surface- area synthetic substrates, matured with suitable cultures, addresses some of these nutritional issues, and has been proven to be a viable and economical alternative to current conventional practices.

(Editor’s Note: This article was originally published in the February 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Jeffrey J. Peterson

MERIDIAN Applied Technology Systems, USA, LLC

[109,111,99,46,115,116,97,109,110,97,105,100,105,114,101,109,64,110,111,115,114,101,116,101,112,106]

Related Posts

Health & Welfare

AHPN inferences based on behavior of vibrio bacteria

Vibrio parahaemolyticus, a strain of which is the cause of acute hepatopancreatic necrosis (AHPN), has both virulent and benign strains. This strain colonizes the stomachs of shrimp by the formation of a biofilm, which protects it from antibiotics and other potential treatments.

Health & Welfare

Fish silage: Bioconverted waste yields useful byproducts

Although its final quality can be variable, fish silage can be an effective protein supplement in feeds for various fish, shellfish and terrestrial animals.

Responsibility

C:N-controlled, periphyton system boosts production in stagnant ponds

The adoption of polyculture systems with controlled carbon:nitrogen ratios and substrates for periphyton development can improve utilization of the aquatic food webs in stagnant ponds.

Responsibility

Reducing nitrogen waste: An integrated approach

In shrimp farming it is critical to ensure that residual nitrogen waste is minimized or eliminated prior to discharge into receiving waters.