Sophisticated machines allow the addition of oil up to 40%

The application of liquids, and fats and oils in particular, is a challenge in animal feed manufacturing. In aquatic feeds, the main liquid feed coating is fish oil.

The traditional methods of fish oil application have involved drum coaters, paddle mixers, and mist-coating units. The major limitation of these types of coaters is the amount of total fat they can apply, which is a problem with feeds for aquatic species that require high-density diets with oil coatings that exceed 15 percent.

Coating at that level of oil inclusion has been extremely difficult, with the main issue the internalization of the oil into the pellets. The high amounts of unabsorbed oil stain feed bags and can even leave a surface film on fish ponds. This lost oil is required to supplement the fish diets as a source of energy and/or polyunsaturated fatty acids such as the omega-3s.

Vaccuum-coating systems offer a method by which to more effectively use higher levels of oil coating. Available since the mid-1980s, vacuum coaters for feeds have evolved into sophisticated machines that allow the addition of oil up to 40 percent. The best units combine a double-paddle mixer with the vacuum system. Double-paddle units ensure proper mixing of the pellets with the oil, which is applied from spray nozzles located at strategic locations to ensure proper dispersion onto the feed.

Temperature

It is important to understand how vacuum pressure affects water temperature. Under vacuum conditions, water boils at lower temperatures. With 20 mbar of absolute pressure, the boiling point of water is 17.25 degrees-C, but at 200 mbar – the vacuum level applied in a vacuum coater – water boils at 60.1 degrees-C.

A vacuum applied when feed pellets are too warm can result in moisture loss from the feed. It is important to cool the pellets to about 50 degrees-C prior to starting the vacuum process.

Vacuum-coating process

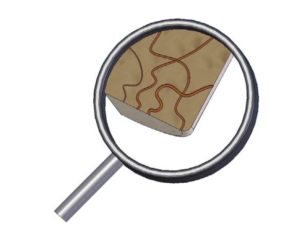

In the vacuum-coating process, vacuum is applied at 200 mbar of absolute pressure to remove air from the feed pores, leaving them as open cells (Fig. 1). Once the vacuum pressure is achieved, oil is sprayed on while the paddles mix the feed with the oil to coat all particles.

Once the oil addition sequence is completed under vacuum, the vacuum pressure is released slowly back to atmospheric pressure of 1,015 mbar. This creates a pressure differential that forces the oil into the voids or pores of the pellets (Fig. 2). However, if the pressure equilibration is done too fast, there is the risk of piercing the oil film coating and allowing air back into the open pores.

Batch system

Because of the steps involved, vacuum coating is done in a batch system. First the feed is proportioned into the fat coater. After the feed is in the feed port, the gate is sealed and vacuum is drawn. Once the product is back under atmospheric pressure, the gate is opened and the product is released into a conveyor that takes it to the packaging bins.

Liquids application

With vacuum coating, liquids such as enzymes can also be applied to feed. In the near future, this technology may be used to coat feeds with fat- and water-soluble vitamins. This would reduce the inclusion levels of the vitamins, which are high to compensate for losses incurred during the extrusion or pelleting processes. The vacuum-coating process is more successful with extruded products that have porous cell structures.

Shrimp feeds

Pelleted shrimp feeds are very dense and have very few if any pores. However, it is possible for extruded shrimp feeds to take advantage of vacuum-coating technology, even at the low 3-6 percent oil or fat addition levels common in shrimp feeds. Vacuum coating extruded shrimp feed can increase the feed’s specific weight, making it more dense and able to sink.

If leaching of nutrients is an issue in sinking feeds, the vacuum-coating process may offer another advantage. Closing the feed pores with oil can improve water stability. The oil is hydrophobic, and having it inside the porous structure reduces the opportunity for water to penetrate the feed.

(Editor’s Note: This article was originally published in the July/August 2006 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Responsibility

Aquaculture byproducts improve sustainability of seafood value chains

Tons of aquaculture byproducts are available as sources for fishmeal and fish oil to supplement the supplies obtained from fisheries. Innovative technologies are supporting more efficient use of these by-products in aquafeed.

Innovation & Investment

Can an oyster-shell paint help rethink artificial reefs?

North Carolina company Shellbond seeks to commercialize a creative product made from shells, believing it could transform oyster farming.

Intelligence

Cost to benefit, fish skin yields unique gelatin products

Fish skin can be processed into food-grade gelatin. Unlike gelatins made from cattle and pig skins, those from coldwater fish remain liquid when not refrigerated.

Aquafeeds

Inside the Cargill Aqua Nutrition aquafeed plant in Scotland

Formed in 2015, following Cargill’s acquisition of salmon feed specialist EWOS to complement its own warm-water aquaculture feed business, Cargill Aqua Nutrition produces feed for salmon, tilapia and shrimp in 20 countries around the world.