Shrimp has become a preferred item for festival seasons, vacations and holidays

Value-added seafood can be defined in different ways. For example, a shrimp farmer can peel a percentage of his crop that is soft-shelled and thus increase its value, rather than decrease income by having to sell the shrimp as a second-grade product.

To gain value, a shrimp or lobster processor can differentiate its products from those of other producers and present a greater variety to importers. The various product presentations are designed to offer laborsaving ways to purchase product for restaurants, retail outlets, and consumer kitchens.

Value adding is traditionally thought of as processing outside straight commodity sales. In fact, farmers or processors can gain extra income not only by further processing of shrimp, but by supplying specific markets with targeted product forms, as well. To generate added value, product can also be differentiated by its means of culture, such as “chemical-free” or “organic.”

Value-added shrimp presentations

Whole shrimp

Whole animals require very little processing in the plant, but the product needs to be treated carefully to avoid physical damage, especially to the head. One difficulty is that this product may require pond side treatment to avoid melanosis, particularly in the case of product for the European Union. Spain and France have a large market for whole shrimp, which is cooked and resold. Product for these markets needs to be of top quality and dark color. Whole shrimp prices vary greatly throughout the year, but can be better than for commodity tails.

Varied cuts

Value adding includes several product forms, and presentations can be raw, cooked, individually quick-frozen (IQF), or block frozen. The simplest cut is an “easy-peel” (E.Z.) shrimp in which a cut is made from the first to the fifth segments, generally to a depth of 30 percent of the segment. The sand vein is then removed. Shrimp can be cut by hand or machine, but generally greater uniformity is achieved with machine-cut shrimp. With practice, though, people can also cut very accurately and uniformly.

Another cut is “peeled and deveined” (P&D). In this method, workers or machines cut from the second to fourth segments. These products are often presented cooked with tails on for shrimp rings at supermarket chains, or skewered for restaurant supply.

The tails can be cut further into butterfly, round, or western cuts with the tails left on or removed. Deveining can be by a machine cut or hand needle. Another alternate type is “peeled undeveined” (PUD), often used for very small sizes that are difficult and laborious to peel.With all these cuts, importers really need to know their suppliers well and specify depth of cut and standards required.

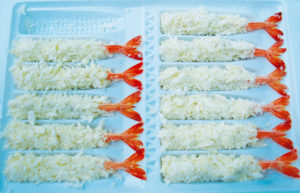

One particular type of item is raw, peeled products like P&D, tail on, straight shrimp used for processing tempura shrimp for Japan. The Japanese Customs Authority categorizes value-added products into several groups, including dried/salted/ in brine, cooked and smoked, and prepared/preserved.

The markets for these products are dominated by supplies from Vietnam, Thailand, China, and Taiwan, which also provide a wide range of other value-added seafood products to the Japanese market. It is worth noting that fish products are still the most highly preferred protein source in Japan. Shrimp has become more of a preferred item for festival seasons, vacations, and holidays. Warm water spiny lobsters and cold water lobsters can also be value added. Spiny lobster tails are often sold with a split back to aid removal of the meat or in an E.Z.-peel version with a small notch in the last segment that grasps the meat and provides a great presentation.

Coated shrimp, ready meals

Increasingly popular for restaurant chains, prebattered or coated shrimp are shipped completely prepared for cooking at the restaurant kitchen, which can greatly help logistics. Frozen entrees, such as ready-to-eat microwavable meals, are also popular. These are the ultimate goal of many operations, but require sophisticated cooking plants and training to achieve the high standards necessary.

Natural products

Shrimp that are chemical-free, all natural, or organic are increasingly in demand, especially in U.S. and European markets. In the United States, shrimp may be sold as organic if they are certified by a foreign certifying body. The U.S. Department of Agriculture is still working on development of its organic standards to allow products to be sold as certified organic in the U.S.

Moisture treatment

Sodium trypolyphosphate (STP) treatment can be used to help retain moisture in shrimp processing but not add weight. Since the temptation exists to deepen cuts, extend dip time, and use excessive percentages of STP, it is important to ask the right questions and know your supplier.

Import trends

Because the current U.S. antidumping tariffs do not affect value added products, this classification of exports to the U.S. has increased in recent years. Countries like Ecuador, China, and Thailand have shifted much of their production to value- added products.

U.S. imports of breaded shrimp increased 169 percent from 16.6 million kg to more than 44.4 million kg in 2005, and then rose another 11 percent in 2006. U.S. imports of prepared shrimp meals jumped 40 percent from 83.4 million kg in 2005 to 116.6 million kg in 2006. China and Thailand now account for 93 percent of U.S. imports of breaded shrimp and 75 percent of the country’s imported prepared shrimp meals.

(Editor’s Note: This article was originally published in the January/February 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Chris Denmark

Quality Assurance Director

Expack Seafood, Inc.

One Woodbridge Center, Suite 915

Woodbridge, New Jersey 07095 USA

Tagged With

Related Posts

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.

Innovation & Investment

Aquaculture in Canada: status, perspectives

Canada exports farmed seafood products to more than 22 countries and is the main seafood supplier to the U.S. market. Finfish, primarily salmon, production is strong and shellfish production is growing, but diversification will be imperative to maintain competitiveness.

Intelligence

Aquaculture key to increasing seafood supplies to Arab states

Arab States have substantial natural resources to increase aquaculture production. Several types of systems are readily adaptable and can be implemented relatively quickly.

Intelligence

Brazilian aquaculture: Constraints and challenges (Part 2)

Brazil will have to deal with an adverse economic and political environment in the next few years. One should expect high value fish products like shrimp, tilapia, Chilean salmon and cod being replaced by more affordable seafood and alternative meats, as consumers keep losing purchasing power due to inflation, unemployment and monetary devaluation.