Technical advances for a full-scale drifter operation commercially viable within a decade

In the face of rapidly increasing global demand for seafood and declining wild fisheries, the culture of marine finfish will need to expand. The vast majority of marine finfish culture currently takes place in nearshore and inshore waters, where conflicts with other coastal users and environmental carrying capacity issues often accompany expansion efforts.

Moving aquaculture further offshore into deeper water reduces both conflicts with shoreline user groups and the environmental impacts of farm scale-up. Offshore, interactions between captive and wild fish populations should be reduced, and the extreme depth of the operating area and wide-ranging motion of a drifting cage over the seafloor should also reduce effects on water quality and benthic habitat. The offshore environment could also provide a healthier, lower-stress environment for the stock, resulting in better growth performance.

The ability to raise fish on mobile farms miles from shore in extremely deep water could present the aquaculture industry with opportunities for virtually unlimited expansion.

Velella project

To examine the feasibility of offshore culture, Kampachi Farms and partner Lockheed-Martin embarked on the Velella Project, a research effort named after a genus of drifting pelagic hydrozoans. Like its namesake, the Velella array would be a drifter, free to move across a vast operating area – the deep, relatively calm seas west of Hawaii Island, Hawaii, USA.

The project’s goals were to test an unanchored, free-drifting mariculture operation, pioneer a permitting pathway for aquaculture in U.S. federal waters, develop the supporting automation and communications technologies required to conduct mariculture in the remote ocean and assess the biological benefits of such a culture system. The Velella Project was made possible by the support of the Illinois Soybean Board, National Science Foundation, International Copper Association and Ocean Farm Technologies.

Rather than anchoring, the array was to remain in its operating area by harnessing natural forces. Predeployment studies validated the hypothesis that the mesoscale eddies generated west of Hawaii were consistent enough to retain a vessel and pen array. Guided by U.S. Navy satellite imagery and Lockheed-developed navigation software, the Velella array would deploy into the Kona eddy field and ride the circular currents, “hopping” occasionally from one eddy to another to stay within reach of land-based operational support.

Putting to sea

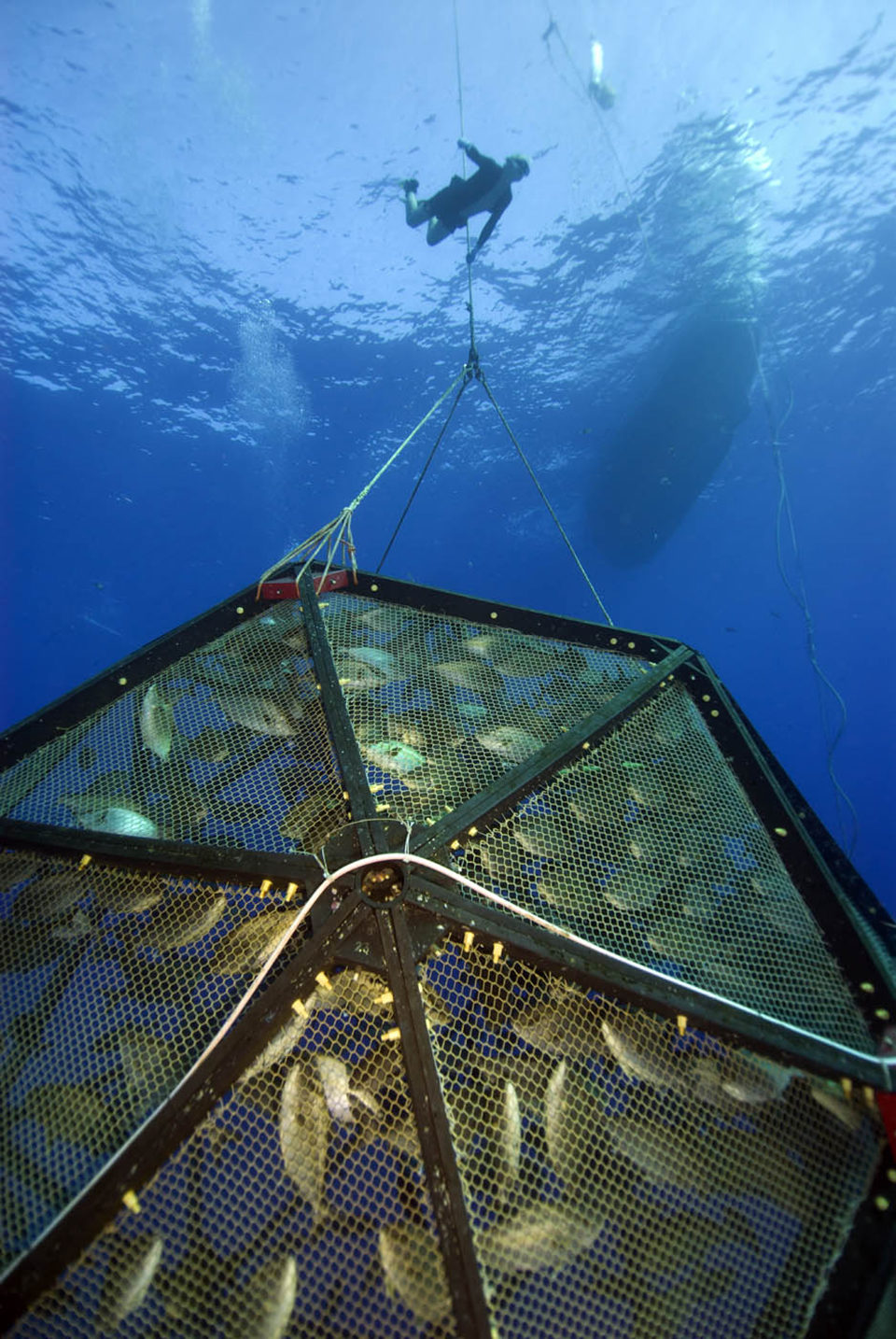

The Velella array consisted of a 132-m3 Ocean Farm Technologies Aquapod with a five-point towing bridle tethered to the 20-m steel schooner S/V Machias using a 122-m nylon towline. This towline also supported the umbilical connections between the pen and shipboard farm systems: a feed hose and two air hoses running from a compressor to the pen’s twin ballast tanks.

When submerged, the pen’s position in the water column was maintained using a string of trawl floats attached to a three-point lifting bridle. The array was deployed from Kawaihae Harbor in May 2011 and towed south and then west into the center of a large Kona eddy, where the pen was submerged, and the array began sea trials including practice drifts and tows, as well as operational drills.

After an extensive year-long review of the project’s environmental assessment, the National Marine Fisheries Service (NMFS) granted a special coral reef ecosystem fishing permit (SCREF) in July 2011. The permit authorized Kampachi Farms to culture and harvest kampachi, Seriola rivoliana, in the designated action area within the U.S. exclusive economic zone.

As the Velella Project was the first of its kind, the NMFS had no permitting or regulatory structures specifically for open-ocean mariculture and therefore used the next most applicable permitting process at its disposal. The issuance of a SCREF permit was deemed necessary, as S. rivoliana is listed as a managed coral reef species, although no fishing activities were planned.

Keahole Point Fish, LLC, (KPF) the operator of the moored Kona farmsite and shoreside hatchery facility, provided kampachi fingerlings and assistance with the stocking of the pen. In July 2011, the Velella research team and KPF personnel transferred 1,889, 180-g fingerlings from nursery tanks to 1-mt plastic totes that were trucked to Honokohau Harbor and craned onto the deck of KPF’s Kona Kampachi, an ex-Navy landing craft.

The Velella array rendezvoused with the Kona Kampachi 21 km off Keahole Point, and the fingerlings were transferred into the cage. The initial mortality due to transfer-related stress was far lower than expected, with only 29 fish dropping out in the first week. The remaining kampachi began to accept a commercial reduced-fishmeal yellowtail diet containing a significant proportion of soy and other agricultural products almost immediately.

The Machias towed the stocked pen back toward the eddy center and resumed drifting. Over the first two months of operations, the array remained adrift 79 percent of the time.

In the field

A team of two divers supported the project on site, operating the feeder system, visually monitoring the feeding, conducting needed repairs and maintaining the cage and rigging. They also stood watch as crew members of the Machias and recorded sightings of wildlife around the array.

The Velella array appeared to have a strong fish-aggregating effect even before it was stocked. The array provided habitat and sanctuary for small planktivores and other marine life, drawing in larger predators such as tuna, mahimahi and sharks. The array also became very popular with local recreational and artisanal fishermen.

In addition to being responsible for daily farm tasks and environmental monitoring, the divers served as the main point of contact for the land-based research team, relaying operational statistics back to shore and working with Lockheed programmers to troubleshoot and update the communications and automation gear. While the individual farm systems functioned well, problems with the satellite link prevented the land-based team from operating them remotely.

Just a fluke

It was anticipated that the combination of the pen’s distance from shore, its nomadic nature and the anti-fouling properties of its brass-alloy mesh netting would limit infestations of parasites, particularly Neobenedenia species skin flukes.

However, in September 2011, routine fish health sampling recorded a single skin fluke, likely transferred to the cultured fish by the large numbers of rainbow runners that shadowed the array when closer to shore. Within two weeks, the population had jumped to 13.5 flukes/fish. While this level was not sufficient to cause serious harm to the stock, past experience has shown that a sharp rise in infestation rates is a precursor to exponential proliferation.

In response, Kampachi Farms initiated an innovative ectoparasite control regimen with two main goals: disrupt the flukes’ life cycle by reducing the available biofouling for egg attachment and limit the free-swimming larvae’s ability to successfully attach to a host.

This was accomplished through a rigorous manual cleaning schedule and a policy of constant forward motion through light towing. The ease with which the mesh could be cleaned allowed the divers to complete two full cleanings of the cage per week. Constant towing provided a unidirectional flow of water through the pen that flushed out fluke larvae as soon as they hatched.

These strategies delivered near-immediate efficacy in reducing skin fluke prevalence to less than 1/fish – lower than for wild fish along the Kona coast. This was the first time a Neobenedenia infestation had been controlled in Seriola culture without the use of chemicals or therapeutants.

Impressive performance

Fish health and growth performance exceeded every expectation. Rapid growth and strong demand for feed resulted in an early feed inventory shortfall, so smaller-than-optimal pellets were fed for two weeks while awaiting a new feed shipment. The kampachi health and resilience were impressive, with only 10 mortalities over the trial period after the initial post-transfer dropout and overall 98 percent survival to harvest.

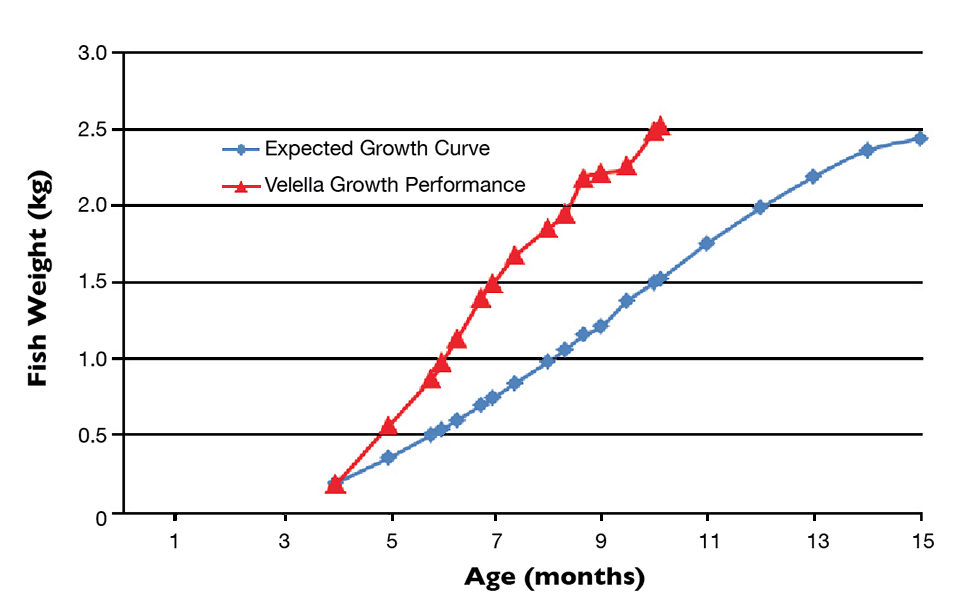

The fish reached harvest size in an unprecedented five months of growout – nearly twice as fast as expected (Figure 1). The feed-conversion ratio for the stock remained below 1.25:1 up to an average fish weight of 2.2 kg, then averaged 1.60:1 for fish up to 2.5 kg.

Grow-out continued until February, which allowed an extra two months to assess whether the enhanced performance would continue beyond the usual harvest size. While the kampachi growth rate remained excellent, feed conversion became less efficient as the fish increased in size. The Velella array was harvested in early February and towed back to Kawaihae Harbor for demobilization after 267 continuous days of operation at sea.

Looking forward

The issuance of a permit to stock fish into a culture system in federal waters was a huge step for the U.S. aquaculture industry. The biological results of this first-ever growout of marine finfish in an unanchored open-ocean farm were also highly encouraging.

The project successfully showed it is possible to run a mariculture operation adrift in the open ocean and identified target areas for future work to bring the concept to commercial viability. Advances in hydrodynamic towable cage technology, broadband satellite communications and satellite-based oceanographic modeling will be required for a full-scale drifter operation to be commercially viable – a confluence of technologies Kampachi Farms believes to be five to 10 years downstream.

However, some challenges can be resolved in the near term to bring the advantages of deepwater mariculture to fruition. Upcoming research will address farm husbandry automation and remote operational control without a crew. The next phase will focus on replicating the biological success of the Velella trial in a single-point mooring in deep water far offshore.

By roughly maintaining an array in position, regardless of currents or ocean conditions, mooring will facilitate remote control of the farm over a commercial wireless broadband link rather than a slow satellite modem. Because a moored Velella array will align itself with the prevailing current, range of motion over the seafloor and unidirectional flow through the cage will be maintained.

(Editor’s Note: This article was originally published in the September/October 2012 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

-

Neil Sims

Kampachi Farms LLC

P.O. Box 4239

Kailua-Kona, Hawaii 96745 USA

Tagged With

Related Posts

Innovation & Investment

At Aquaculture America 2018, signs of support for thriving domestic industry

Aquaculture must reshape its public narrative in order for the blue revolution to transpire. That’s what many prominent voices were saying at the World Aquaculture Society’s annual U.S. conference in Las Vegas.

Intelligence

As ocean temperatures rise, so too will vibrio outbreaks

A study using a half-century of data has linked climate change and warming sea temperatures with an increase in illnesses from the common vibrio bacteria. Shellfish growers, fighting a particularly virulent strain of Vibrio parahaemolyticus, are changing their harvest protocols.

Innovation & Investment

Offshore aquaculture inches closer to reality in the Gulf of Mexico

New U.S. policies for offshore aquaculture permitting will soon be put to the test in the Gulf of Mexico. With imported products dominating the U.S. seafood landscape, some argue the time has come for the industry to take a leap forward.

Innovation & Investment

Opinion: Stop offshoring offshore aquaculture

Something must change if the U.S. government hopes to encourage rather than discourage aquaculture, particularly in federal “offshore” waters. Neil Sims says it’s time to stop exporting knowledge, innovation and investment.