Eight aquaculture businesses pitch to investors in the accelerator’s latest ‘Demo Day’

Hatch Blue, the Norway-based aquaculture business accelerator, streamed its latest startup show-and-tell session online on Dec. 3 and unveiled eight “new” growing businesses, all members of its fourth cohort.

Wayne Murphy, partner and co-founder of the accelerator, said at the outset that each of the eight companies “demonstrated an incredible grit and determination to succeed” despite the challenges of working remotely during the coronavirus pandemic of 2020. Under normal circumstances, the Hatch team and its global network of sponsors and mentors would work closely with each new-business leader, taking them to sites around the world where aquaculture innovation and technology is advancing and being put into practice at commercial scale – places like Bergen, Norway; Hawaii, USA; and Singapore, to name a few.

The object of the 16-week accelerator program is to coach the businesses, which are typically at a very early stage in their respective developments, and prepare them to meet investors; some businesses are further along and want the immersive experience and access to aquaculture expertise. Demo Day requires the cohort members to pitch to a live audience, which has taken place in either in Norway or in Hawaii, where Hatch has an office at NELHA, the National Energy Laboratory of Hawaii, in Kona.

Instead, this time the eight companies delivered their pitches online, each with a roughly 5-minute prerecorded pitch film followed by a question-and-answer session of the same duration. Here are the members of the fourth Hatch cohort:

The Plant Based Seafood Company

Georg Baunach, managing partner and co-founder of Hatch, said at the beginning of Demo Day that alternative meats are a hot topic, and finding a plant-based protein company was a priority for the accelerator and its investment fund, which earlier this year launched with $8.4 million in capital.

Conveniently named, The Plant Based Seafood Company (Gwynn’s Island, Va., USA) was founded this year, but its leadership team has been in the seafood industry for years. Monica van Cleve-Talbert, CEO and co-founder of the all-female and family-owned company, said that its products are already in the marketplace and are winning over lifelong seafood consumers with quality and authentic flavors, which she said are “indistinguishable from its seafood analog.”

Using “functional ingredients” to “imitate the sea animal” – vegetables like artichokes, hearts of palm, green cabbage and the Japanese yam or Konjac root – the company makes products like “Bang Bang Shrimp” and sweet ginger scallops. It also has lobster, crab and fish-fillet products in the pipeline.

“We know exactly what seafood is supposed to look, smell and taste like,” said van Cleve-Talbert. While there are many alternative meat products on the market today, “none are as convincing as ours,” she added. Its products contain no gluten, dairy, corn or soy.

The Plant Based Seafood Company is raising funds for R&D, for increasing its “speed to market” and for branding efforts.

ExciPlex

Daryl Staveness founded Michigan, USA-based ExciPlex just six months ago to capitalize on a unique opportunity: “turning molecular discoveries into global impacts.”

ExciPlex can detect mycotoxins in animal feeds, already a big industry but one that Staveness is ripe for disruption with cutting-edge photochemistry, his expertise. This method of diagnostics, he said, is five times faster than existing products and addresses a key pain point for the industry. Exciplex can define properties in feed ingredients, unique signals that can be tested in a lab or in the field, sending results to users with smartphones.

“It’s a proprietary technology unlike anything in the field of diagnostics today,” said Staveness, who said the company would target diagnostics labs first, then grain mills and then eventually would develop an on-farm model, as all links of the animal-feed value chain can suffer massive losses from mycotoxins in their feeds and feed ingredients. “We can ensure that no animal will have to ingest these poisons again,” he added.

ExciPlex is seeking a strategic partnership with an animal nutrition company and hopes to build out its team soon.

Susewi

“We don’t need to go to the oceans for microalgae. We can grow it in the deserts,” said Keith Coleman, CEO and cofounder of Susewi. The company’s existing 30,000-square-meter farm in Morocco is already the world’s largest, he claimed, but there are also plans to expand to another farm in Oman and a 1-million-square-meter facility in the Sahara Desert.

Using only sun, seawater and wind (su-se-wi) as inputs – all of which are free – Susewi can grow a wide variety of organisms in its shallow raceway ponds, greenhouses and a harvesting system that Coleman said was inspired by the mining industry.

Offering operational scalability, the Suswei system is adding IoT (Internet of things) equipment at every phase to monitor growth and quality and is implementing AI (artificial intelligence) to analyze behavior and to optimize growth characteristics. Its facilities use robotics to operate the farms.

“We’ve been told we have the most advanced digital aquaculture platform in the world,” Coleman said, adding that the London-based company seeks series B funds to expand operations. “I can’t think of a more scalable opportunity. It’s highly profitable.”

https://www.aquaculturealliance.org/advocate/sunlight-seawater-and-wind-a-simple-recipe-for-ambitious-algae-grower-susewi/

Sea Warden

Aquaculture has data collection issues and Zach Dinh and Shelby Oliver, cofounders of Sea Warden (Kona, Hawaii, USA) are here to solve them, starting with those belonging to shrimp farmers.

Based at NELHA in Hawaii, Dinh and Oliver have developed monitoring tools that offer farmers new methods to treat diseases, reduce or eliminate antibiotic usage, bring ease to operations and increase profits.

Identifying a market of 250,000 shrimp farmers around the world, Dinh and Oliver said their services include satellite-observation of shrimp pond fallowing and emptying activities, which are potential indicators of disease outbreaks. The idea is to “turn data into actionable insights,” said Dinh.

The company – launched earlier this year – also hopes to improve farmers’ access to financial products. The data it collects would also de-risk investments.

With its eye on Vietnam and Indonesia as the initial target markets, Sea Warden hopes to then expand to India, Thailand and Ecuador, all of which are the top shrimp producers in the world. It will also begin a pilot program with the Aquaculture Stewardship Council next year, an effort to expand access to certification and reduce audit costs.

Seeking $500,000 in a seed round, the company aims to build its team and secure some strategic partnerships to meet its goal of making “large-scale assessments possible to drive meaningful change.”

ANB Sensors

The most important water-quality parameter is pH, according to Kay McGuinness with ANB Sensors, based in Cambridge, UK. Offering pH-monitoring equipment that does not require constant calibration, ANB claims it can offer “timely data like never before.”

“In aquaculture, pH is so important. Fish are totally dependent on the water to eat, feed, breathe and reproduce,” said McGuinness. But the pH technology used today, the glass electrode, was developed in the 1950s and has seen “little innovation” since then, she added.

Made of glass, typical electrodes are therefore fragile and need to be manually calibrated to maintain accuracy. ANB offers a solid-state sensor with plastic or titanium parts that are better suited for harsh environments. Typical pH sensors’ references points tend to “drift” over time, and while ANB technology can’t stop the drift, it can track it, allowing the device to self-calibrate.

It’s also quite versatile: “It can work in various media, from aquaculture to a cow’s stomach,” she added.

ANB, which holds two patents, is seeking growth funds and is recruiting a commercial director.

https://www.aquaculturealliance.org/advocate/entrepreneurs-need-toughness-commitment-thrive-hatch/

C-FEED

With shrimp and finfish hatchery nutrition needs at a premium in aquaculture worldwide, C-FEED of Trondheim, Norway, is already making major inroads with producers in multiple countries and with multiple species.

The company produces live copepods for early-lifestage dietary needs, offering hatchery operators strong survival, growth and quality output at a reduced cost from existing solutions, said CEO Tore Remman. With 15 years of R&D under its belt, C-FEED is hardly a startup.

“We’re working with large companies” in northern Europe, Remman said, with a keen focus on cleaner fish. Much of Norway’s world-leading farmed salmon industry deploys lumpsuckers in their net pens to feast on sea lice.

“The production of cleaner fish is a huge, growing market for us,” Remman said, adding that it’s working with companies like Mowi and Leroy already. It is selling its product to companies in Thailand and made its first shipment to Singapore recently. Overall, C-FEED’s copepod product – which has a gray liquid appearance and that Remman likened to “mother’s milk” for fish fry – has been involved in 35 feeding trials with 22 species globally, Remman said. “We’ve seen a lot of hatcheries,” he added.

C-FEED is in the process of raising €4 million for expansion.

Blue Lion Labs

Initially focused on shoring up drinking water issues, Blue Lion Labs of Waterloo, Ontario, Canada, has already made a pivot to aquaculture. Founded this January, the company saw in aquaculture the opportunity to “build something novel.”

Identifying algae blooms and sea lice outbreaks is a task that salmon farmers would like to perfect in order to better protect their fish and their profits, yet it is one that is prone to human error, said Jason Deglint, CEO and cofounder. Existing solutions tend to only “deal with the problems after they happen,” he said. Blue Lion can offer producers early warning signs to mitigate impacts.

Deglint said he originally set out to work on a problem that “affected everyone on the planet” after earning his Ph.D. just a few years ago. He and Katie Thomas, cofounder and COO, are combining their respective expertise in systems design engineering and aquatic ecology in this new effort. With only one other employee on staff, the nimble firm has nevertheless already participated in five other accelerator programs.

SmartOysters

Oyster farmers really just want to be able to sleep at night, said Ewan McAsh, CEO and cofounder of SmartOysters, a farm-management software and application provider based in Australia. And, of course, grow more oysters.

McAsh would know, as he was a farmer himself for more than 15 years.

“There is a need for farm management software in the broad aquaculture community,” he said. “We can deliver a lot more than database systems, and in a format that farmers understand.”

Available to farmers globally, the SmartOysters app uses GPS technology, among other tools: “That’s how farmers visualize their farms,” he added.

But few use modern technology, and most rely on memory for maintenance tasks, which McAsh said is “a hard habit to break out on the water.”

When he was farming oysters, “All the history, all the best practice was in my head. I became trapped as the farm manager, working the business day to day. Any effort to grow the business became a burden, not an opportunity.”

The SmartOysters app allows these busy producers to track their gear and inventory, assign and track production and maintenance tasks and display data in easy-to-read graphs and tables. The data collected can make oysters businesses more efficient, scalable and investable, he added. With all that help, farmers – like the dozens he’s already recruited in Australia, New Zealand, U.K., Ireland and North America – are surely resting easier.

SmartOysters, founded in 2017, is seeking $1 million or more in expansion funds.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

James Wright

Editorial Manager

Global Aquaculture Alliance

Portsmouth, NH, USA

Tagged With

Related Posts

Innovation & Investment

Little fish in a big pond: Minnowtech aims to give fresh vision to shrimp inventory

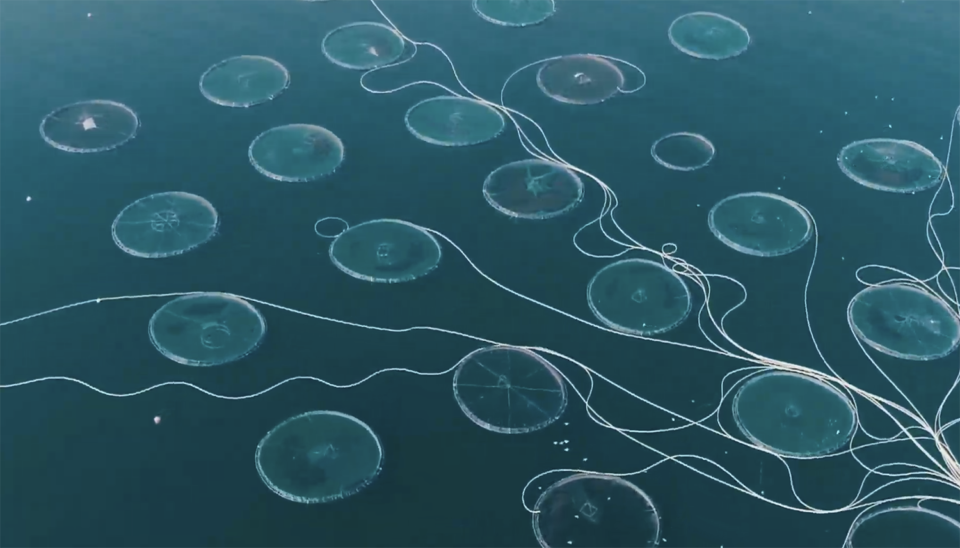

Because shrimp farmers lack accurate in-pond inventory, startup Minnowtech is on the verge of offering a data-driven solution. It’s got something to do with jellyfish.

Innovation & Investment

Hatch opens six-pack of winning aquaculture innovators at Demo Day

Demo Day in Dublin, Ireland, last week marked the conclusion of the Hatch aquaculture business accelerator’s second cohort in 2018.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Innovation & Investment

Scottish firm honing bacteriophages into aquaculture-disease assassins

Scottish biotech firm Fixed Phage aims to bottle the powers of bacteriophages to deploy these “bacteria killers” on some of the world’s most destructive aquaculture diseases.