Checklists for manufacturers and farmers

Best management practices, or BMPs, are written plans that describe operational practices of almost any type of endeavor, but in general, they are developed for manufacturing or production operations. BMPs are sometimes developed to ensure compliance with regulations, but more commonly are established to promote efficient operation and thus elimination of wasteful practices. Applying BMPs is usually in the best interests of business operators because BMPs are nothing more than solid, common-sense practices that smart businesses follow anyway.

BMPs for salmon feed

BMPs for salmon feed and feeding fall into two categories: one for the feed manufacturers and the other for the farmers. BMPs for feed manufacturers can cover aspects of feed formulation, evaluation and selection of feed ingredients, manufacturing methods, and feed storage and handling. For salmon farmers, BMPs cover feeding practices that include the amount, frequency, and delivery of feed; pellet size selection; feed storage and handling; and feedback systems in pens that detect uneaten feed that might be lost through the pen bottoms.

BMPs for manufacturers

Using ingredients they purchase from others, salmon feed manufacturers produce feed they sell to farmers for a profit. Feed producers all have access to the same ingredients and manufacturing equipment, so they must rely on their knowledge of ingredients, relationships with ingredient brokers, formulation and manufacturing skills, and efficiency of operation to produce competitive products. They must also comply with regulations and guarantee fish health and performance.

BMPs can be helpful in this complicated business, both in the manufacturing process and to define practices that help maintain feed quality during storage and shipment. BMPs for salmon feed production are similar among companies.

Manufacturing BMPs pertain to operating manufacturing equipment within narrow specifications, maintenance of equipment, cleaning, and so on. BMPs for feed quality and storage are common-sense ones that include the use of appropriate bags to prevent moisture or contamination of pellets, and avoiding practices that lead to pellet damage, such as standing on or throwing bags, and improper stacking. Other BMPs cover storing feeds in dry, cool, vermin-proof areas, and using proper labels and expiration dates.

BMPs for farmers

Livestock and poultry are generally allowed unlimited access to feed, but this is not the case in salmon farming, where the fish must be fed by farmers. How much salmon should be fed each day, and in how many feedings?

Farmers’ motivation in feeding salmon is to obtain the highest practical conversion of feed into fish weight gain. This involves feeding at a level that supports near-optimum feed-conversion ratios and avoids feed losses. Feeding the proper amount in such a way that feed is used most efficiently is not simple, and there is no formula or chart that is appropriate for all farms.

Feeding charts have been developed to guide farmers in selecting appropriate amounts to feed each day, but they are only guidelines, not absolutes. Feed intake can vary with the weather, day length, water quality, tides, presence of predators, and other environmental variables. The species, strain, and size of the salmon also affect feed intake.

Therefore, salmon farmers must gauge feeding intensity every day and make appropriate adjustments to feeding levels based on how the fish are feeding. Accurate feeding records must be kept to allow rational assessment of feed efficiency during production and assemble data for future use.

Feed conversion

Feed-conversion ratio is the ratio of the amount of feed fed to a tank, raceway, or pen of fish over a defined period of time divided by the total weight gain of the fish over the same period. Thus, to calculate feed-conversion ratio, or feed efficiency ratio (weight gain per feed fed), one must know the number of fish in the pen, their average starting and ending weights, plus the amount of feed fed over the period.

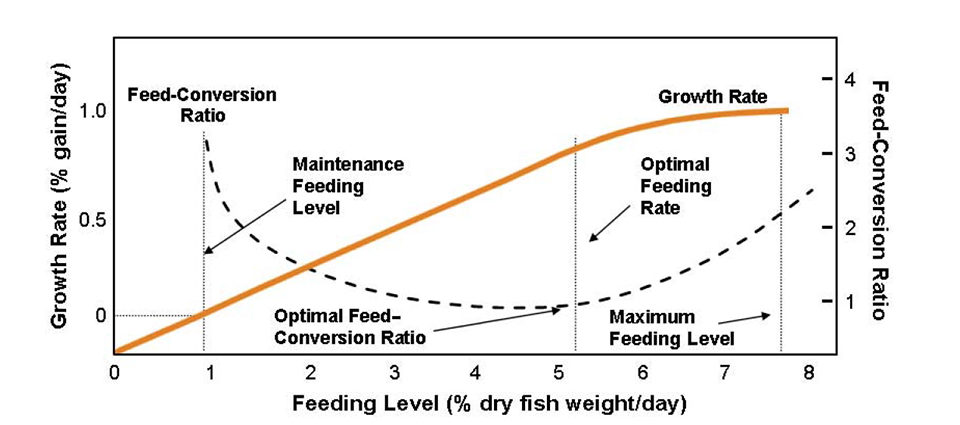

Feed-conversion ratios vary with feeding level, decreasing from the maintenance level at which fish neither gain nor lose weight to the optimum feeding level, and then increasing as feeding levels increase to the maximum amount the fish will eat (Fig. 1). The goal of farmers is to feed at a level that strikes a balance between optimum feeding level and maximum growth. Using high-energy feeds and best feeding practices, feed-conversion ratios of less than 1.0:1 can be achieved on salmon farms.

Feeding frequency and delivery

Feeding frequency is another management tool used by salmon farmers to achieve efficient use of expensive salmon feeds. Salmon consume most feed early and late in the day, so the best approach is to feed large meals after dawn and before dusk, with small amounts supplied at intervals between the large meals. Feeding in this manner ensures that all fish within a pen are supplied with feed, not just the most aggressive animals.

Mechanical feed delivery systems have replaced hand feeding in most salmon farms. Pneumatically driven, these systems blow feed through tubes to individual pens on a farm. The amount of feed delivered to each pen can be precisely controlled, and the use of air rather than mechanical conveyers to deliver the feed virtually eliminates pellet damage and subsequent waste.

Another management tool used by salmon farmers is feed waste detection that tells when feeding activity at depth within pens slows to the extent that feeding ceases to prevent uneaten feed from falling through the bottoms of the pens. Sonar, underwater cameras, feed collection and lift systems, and other devices have been developed to detect feed near pen bottoms. Their use has greatly reduced the amount of feed that is lost.

Recommended BMPs

Based upon the considerations described above, BMPs for salmon feeding should include the following:

- Farmers should use efficient feeding practices.

- Feeding equipment should be regularly checked to ensure efficient operation.

- Farmers should regularly calculate feed-conversion ratios.

- Farmers should optimize culture conditions to reduce feed-conversion ratios.

- Farmers should conduct employee training in feeding methods.

- Farmers should employ feed-monitoring techniques.

- Feed storage, handling, and delivery methods that minimize waste and pellet disintegration should be followed.

- Feed storage areas should be secure, dry, and free of vermin, including birds.

- Feed should not be used past manufacturers’ recommended use dates.

(Editor’s Note: This article was originally published in the April 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Ronald W. Hardy, Ph.D.

Professor and Director

Aquaculture Research Institute

University of Idaho

Hagerman Fish Experiment Station

3059F National Fish Hatch Road

Haggerman, Idaho 83332 USA

Tagged With

Related Posts

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Innovation & Investment

20 years of the Global Aquaculture Alliance

A timeline of key milestones and achievements by the Global Aquaculture Alliance and its third-party aquaculture certification scheme, Best Aquaculture Practices (BAP).

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Health & Welfare

A look at aquaculture in Guyana

With its large quantities of water and little industry to pollute it, Guyana has the potential to become a greater player in global aquaculture.