Nutrition research for SPF stocks

Feeds have a profound effect on animal performance at aquaculture farms, and they represent the largest operating cost in shrimp farming. However, the formulation of commercial Penaeus monodon feeds is based mostly on research conducted on first-generation stocks reared in clearwater and on performance in commercial ponds. Public data on optimizing nutrient and ingredient levels and feeding methods for practical shrimp farming systems are scarce.

A nutrition program was established in Brunei as an integral element of the technology program for production of large black tiger shrimp, Penaeus monodon. It enables the development of specialized diets for key life stages to improve performance and reduce cost. Also, side-by-side operation of nutrition and breeding programs enables optimization of diets and feeding methods for changing nutritional requirements, feed intake and efficiency, and response to dietary ingredients as the animals progress through domestication and genetic selection.

Objectives

The nutrition program has two main objectives. One is to develop high-performance feeds for P. monodon raised in the breeding program. Shrimp in the breeding program are mostly raised in indoor raceways, where they are completely dependent on feed to grow and reproduce. They need diets that support fast growth to sizes in excess of 100 g. Cost is secondary to performance in these diets.

The second objective is to optimize diets for the culture of P. monodon in ponds, where performance needs to be cost effective.

Facilities

The Shrimp Nutrition Research Center (SNRC) in Brunei Darussalam consists of a feed preparation unit and facilities for conducting feeding trials on larval, juvenile and adult shrimp.

Microcosm tanks for conducting feeding trials on grow-out diets were adapted from designs originally developed by the Oceanic Institute in Hawaii, USA, to simulate natural conditions in grow-out ponds. The tanks are housed under a transparent roof to allow the growth of phytoplankton. Airlift pipes in the tanks enable continuous vertical and horizontal mixing of the water column. The tanks are fitted with self-cleaning systems that concentrate solid wastes outside the tank to more accurately gauge feed consumption and enable flushing of feces and excess feed once or twice a day.

Trials

Since the inception of the nutrition program, 28 feeding trials have been conducted in the SNRC. Initially, trials were conducted with specific pathogen-free (SPF) Litopenaeus stylirostris to develop and test the fundamental processes and systems until SPF P. monodon were available. The transition to P. monodon was smooth, and noticeable improvements were observed in the shrimp’s tolerance to high-density juvenile rearing and handling as the shrimp progressed through domestication.

Early research focused on establishing performance benchmarks using commercially available feeds. The feeds were tested in feeding trials and analyzed in commercial laboratories to understand their nutrient profiles, especially amino acids, fatty acids, cholesterol and minerals. Correlates of performance were then derived to establish priorities for future research.

Typical grow-out feeding trials are six to eight weeks long and use five replicate tanks per treatment. Shrimp of 1 to 5 grams in size are stocked at a density of 20/m2. Survival generally exceeds 95 percent.

On a standard diet similar to commercial feeds, the shrimp typically grow at 1.4-1.6 grams/week to reach 14 to 16 grams by the end of the feeding trial. On high-performance feeds, growth rate is 2.0-2.2 grams/week to reach 17 to 22 grams. In a variant from the typical duration of trials to determine whether growth is limited by tank size, P. monodon grew steadily to a size of 67 grams in the tanks.

Feeding trials have been used to evaluate commercial feeds, develop high-performance feeds, investigate attractants and palatability factors, test feed ingredients and additives, test nutrient levels and ratios, and determine the nutritive value of various fat components in poultry by-products. The trials resulted in a high-performance feed that outperforms commercial feeds for P. monodon growth in indoor systems. The authors have also developed feeds with no fishmeal that provide performance similar to feeds containing about 20 percent fishmeal.

Fishmeal replacement

After evaluating a number of ingredients and studying the global ingredient situation, attention focused on soybean products and poultry by-product meal as viable options to replace fishmeal in shrimp feeds.

In one study, poultry by-product meal was found to contain significant levels of key attractants and palatability factors, such as short-chain peptides (Figure 1) and nucleotides. Although the levels were less than those in fishmeal, low-level dietary inclusion of krill, an ingredient with high levels of attractants and palatability, resulted in the poultry meal diet performing as well as a fishmeal diet. Similarly, inclusion of krill or tuna fish hydrolysate improved the performance of diets in which a combination of soybean meal and soy protein concentrate replaced almost all fishmeal.

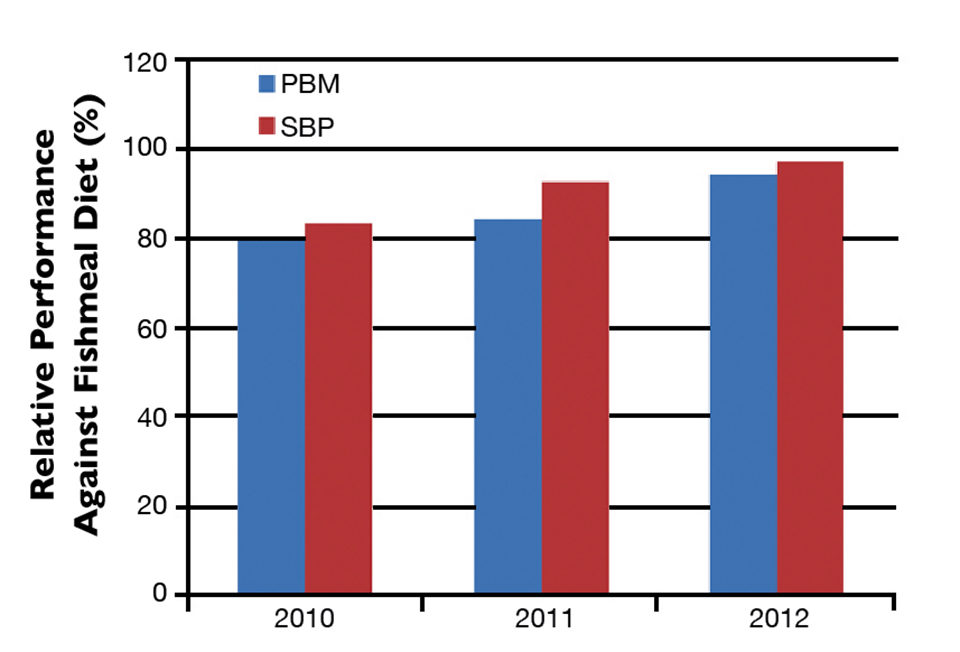

By replacing nutrients and functional factors that are lost when fishmeal is removed from formulas, complete replacement of fishmeal in shrimp feeds is possible when macroingredients like poultry by-product meal and soybean products are supplemented with microadditives (Fig. 2).

(Editor’s Note: This article was originally published in the November/December 2012 print edition of the Global Aquaculture Advocate.)

Authors

-

Victor Suresh, Ph.D.

Integrated Aquaculture International

3303 West Twelfth Street

Hastings, Nebraska 68902-0609 USA -

Emma Farhana A Pakar

Abidah Hj Mohd Yazid

Department of Fisheries, Brunei Darussalam -

Babu Rathinam

Integrated Aquaculture International

3303 West Twelfth Street

Hastings, Nebraska 68902-0609 USA -

Hj Abd. Arif Faiz

Integrated Aquaculture International

3303 West Twelfth Street

Hastings, Nebraska 68902-0609 USA

Tagged With

Related Posts

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 5

The final article in a series about a project in Brunei to develop technology for production of black tiger shrimp focuses on the development of advanced grow-out ponds and practices with enhanced systems for biosecurity, sludge removal, water reuse, energy efficiency, automatic feeding and mechanical harvesting.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 3

Specific pathogen-free offspring developed from founder populations of P. monodon collected from Brunei coastal waters were introduced into a biosecure breeding program, where they have been reared to the fifth generation using family-based selection for reproduction and growth.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 2

For a five-year project undertaken in Brunei Darussalam to develop advanced technology for production of large black tiger shrimp, a comprehensive disease diagnostic laboratory was developed to enable detection of known and emerging shrimp pathogens by molecular and histological methods.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 1

A five-year project was undertaken in Brunei Darussalam to develop advanced technology for the production of large black tiger shrimp. A combination of technologies has enabled efficient production of large-sized black tiger shrimp, which could lead to a resurgence of this species in Asia.