Tilapia production results show technology’s potential

The In-Pond Raceway System (IPRS) as a strategy to increase fish production with reduced environmental impact has been promoted by the U.S. Soybean Export Council (USSEC). The IPRS’s concept is to concentrate fed fish in cells or “raceways” within a pond and provide them with constant water circulation to maintain optimal water quality and to improve feed management. The IPRS also has the potential to reduce solid waste loading in the pond by concentrating and removing it from the downstream end of raceway units.

Water circulation, mixing and aeration are critical elements to this approach because it accelerates assimilation of organic loading of the pond feeding the fish. Some of the challenges that this system faces include potential for disease outbreaks due to higher densities in some species and the need for having back up electrical energy. However, the IPRS allows for more effective prophylactic treatments for managing fish health, and ultimately higher annual yields from the pond.

The technology for in-pond raceway systems (IPRS) has been under development since the early 1990s, but only recently has started been evaluated and adopted in commercial settings. The IPRS research project in recent years has been supported and led by USSEC, the Soy Aquaculture Alliance, Auburn University, the Alabama Cooperative Extension System, the Alabama Agricultural Experiment Station and Pentair Aquatic Eco-Systems, with the objective of improving the economic efficiency and profitability of fish farm operations.

In 2006, Auburn University began evaluating a commercial-scale unit that was developed at a catfish farm in western Alabama, USA. After seven years, this production technology was introduced and began being adopted in China (2013-2014) and in Vietnam (2016), and most recently in Mexico (2017). This article presents results from the first demonstration using an IPRS established at a commercial tilapia farm in Mexico.

Production demonstration setup

The IPRS was installed by the farm owner at a tilapia farm known as Tilapia La Granja in Campeche (Campeche, Mexico). The system was constructed within a 2.6-hectare traditional earthen pond with an average depth of 1.2 meters.

The system, built as a fixed floor project (not a floating model), was installed on a poured concrete wall footing with pond liner bottoms, and consists of seven raceways (cells), each with dimensions 5.0 m x 25 m x 1.20 m (150 cubic meter raceway volume) with a freeboard of 0.30 m. The total culture area of the raceways for holding and growing fish is 875 m2 (1050 m³), which represents 3.4 percent of the total surface area of the production pond. The raceways are equipped with five regenerative blowers providing 2.15 horsepower (60 Hz) per raceway. Additionally, the pond has Asian-style paddlewheels installed in the open water area, which helps mix and circulate water around the pond.

Stocking of tilapia in traditionally-managed earthen ponds in commercial farms at this time is typically 2-3 fish/m2 of pond area (considering ponds averaging 1 meter or slightly more in average depth). By comparison, the IPRS cells use a confinement production strategy and were stocked in this project at densities, ranging from 54 to 116 fish/m3.

In this production demonstration in a commercial farm, raceways were stocked based on limited availability of fingerlings over a 60-day period, with an initial stocking weight of 2.0 kg/m3 of raceway volume. The first raceway was stocked with 8,000 fingerlings with an initial average weight of 35 g per individual (stocking biomass of 1.88 kg/m3 or corresponding to 54 fish per cubic meter of raceway volume).

Afterward, three additional raceways were stocked with 17,000 fingerlings with initial average weights ranging from 17.2 to 18.8 g per fingerling (average stocking weight of 2.06 kg/m3 in the raceway, or the equivalent of 113 fingerlings per m3 of raceway volume). Finally, the last three raceways were stocked with 14,600 to 17,400 fingerlings per cell and with initial average weights ranging from 13.1 to 17.7 grams (biomass at stocking from 1.37 to 2.04 kg/m3 or 97 to 116 fingerlings per m3 of raceway volume).

Results

Production parameters from this IPRS trial are summarized in Table 1, and results should be reviewed in three separate groups. The first group includes raceways 4 and 3, which were stocked at a biomass of 1.88 and 2.13 kg/m3 (or 8,050 and 17,002 fingerlings per cubic meter of raceway volume, respectively). After 110-days, they were harvested after reaching a biomass of 27.69 and 26.99 kg/m3, respectively.

We consider these two raceways to be outliers when their production parameters are compared to those achieved in the other five raceways. Their output had the lowest gross biomass but demonstrated the highest specific growth rate (2.60 and 3.07 percent gain/day). This is understandable because raceway 4 was stocked with the largest stocking size (average weight 35.0 g per individual) but with only 8,000 fish. Similarly, raceway 3 – even though it was stocked with 17,000 fish (average weight 18.8 g per individual) – experienced a severe mortality (57 percent) due to a human error: an incident where air flow to this raceway was accidentally interrupted.

Arana, IPRS, Table 1

| Variable | RW-4 | RW-3 | RW-2 | RW-1 | RW-5 | RW-6 | RW-7 |

|---|

Variable | RW-4 | RW-3 | RW-2 | RW-1 | RW-5 | RW-6 | RW-7 |

|---|---|---|---|---|---|---|---|

| Production cycle (days) | 110 | 110 | 116 | 115 | 132 | 122 | 131 |

| Number of fish stocked | 8,050 | 17,002 | 16,684 | 17,122 | 17,304 | 17,366 | 14,609 |

| Survival rate (%) | 84 | 43 | 92 | 89 | 78 | 83 | 82 |

| Initial avg. individual weight (g) | 35 | 18.8 | 18.8 | 17.2 | 17.7 | 13.1 | 14.1 |

| Final avg. individual weight (g) | 612 | 550 | 580 | 525 | 645 | 510 | 500 |

| Initial biomass (kg) | 281.8 | 319.6 | 313.7 | 294.5 | 306.6 | 227.5 | 206 |

| Final biomass (kg) | 4,153 | 4,049 | 8,906 | 7,971 | 8,740 | 7,323 | 5,998 |

| Initial biomass (kg/m3) | 1.88 | 2.13 | 2.09 | 1.96 | 2.04 | 1.52 | 1.37 |

| Final biomass (kg/m3) | 27.69 | 26.99 | 59.37 | 53.14 | 58.27 | 48.82 | 39.99 |

| Specific growth rate (% gain/day) | 206 | 3.07 | 2.96 | 2.97 | 2.72 | 3 | 2.72 |

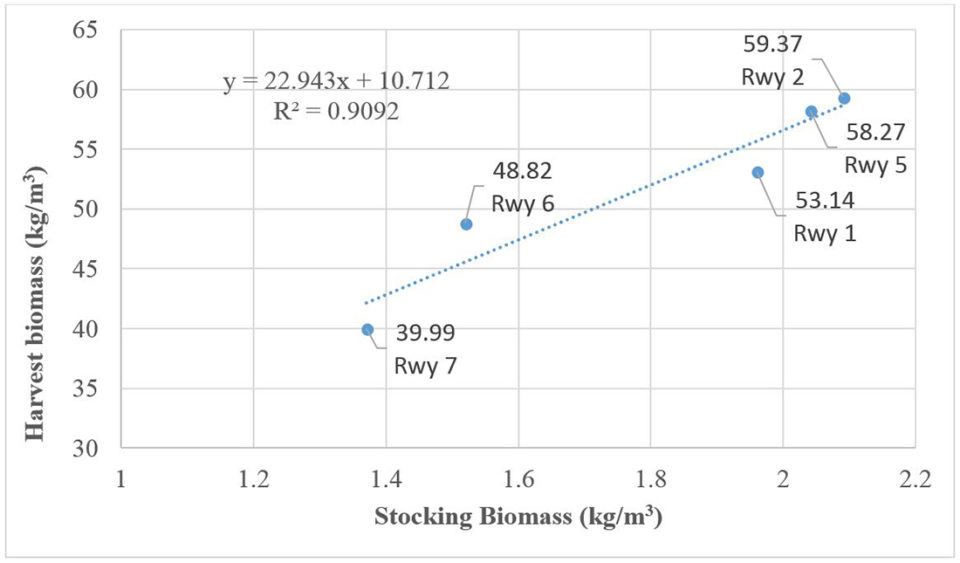

The second group of results includes raceways 1, 2, and 5. These raceways were stocked with 17,037±317 fish per raceway, with an individual average weight of 17.9±0.8 grams and average biomass at stocking of 2.03±0.06 kg/m3 of raceway volume. These raceways were harvested after 116 days (raceways 1 and 2) and 132 days (raceway 5), respectively, with a final biomass of 56.9±3.3 kg/m3 of the raceway. The average specific growth rate for this group was 2.88±0.14 percent gain/day.

The third group of results includes raceways 6 and 7, stocked with 17,366 and 14,609 fish per raceway (115.8 and 97.4 fingerlings m³), respectively. Fingerlings stocked into these two raceways were the smallest fish with individual average weights of 13.1 grams and 14.1 grams, respectively. Biomass at stocking for raceway 6 was 1.52 kg/m3 and for raceway 7 it was 1.37 kg/m3. The biomasses at harvest were 48.82 and 39.99 kg/m3, respectively, in these two units.

The relationship between stocking and harvest weight in terms of biomass (kg) per volume (m3) for the latter five raceways exhibited a linear relationship (R2=0.90473), which may indicate the potential of this system for sustaining higher densities without affecting the growth. In these five raceways, Nile tilapia showed a specific growth rate of 2.88±0.14 percent gain/day (CV=4.8 percent) (Fig. 1).

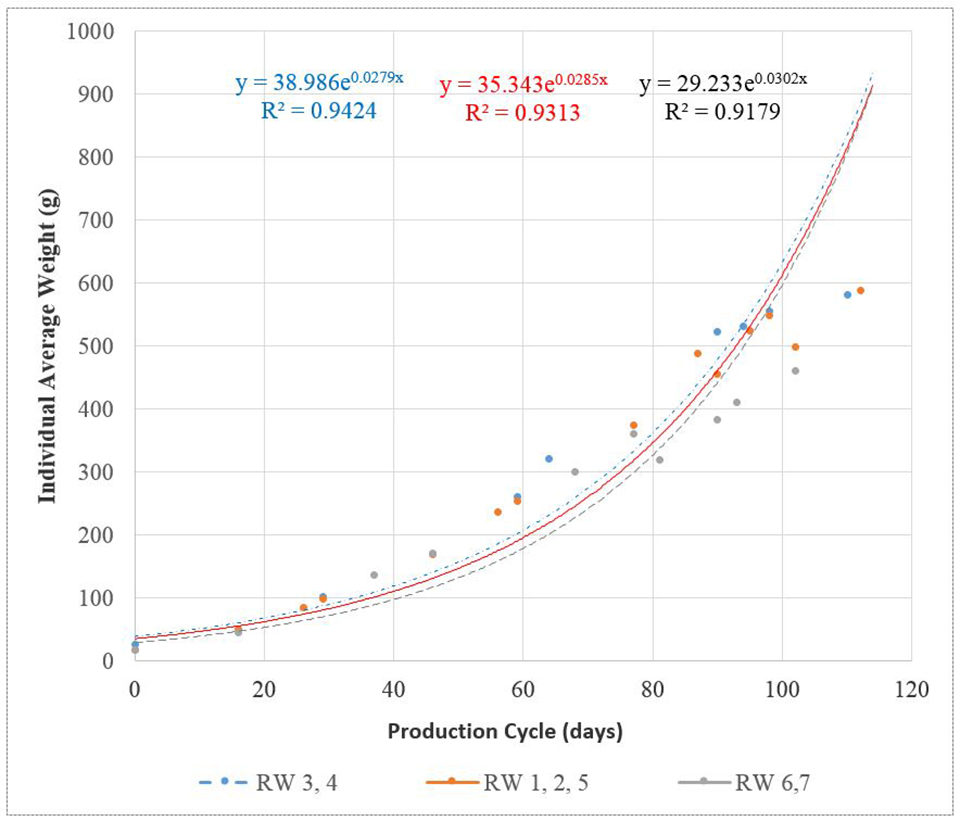

Growth performance during this production demonstration was similar for the three groups of raceways: 3-4, 1-2-5 and 6-7 (Fig. 2). Growth performance also may point out the potential of the IPRS for maintaining higher biomass in the raceway cells without negatively affecting the rate of growth response of Nile Tilapia.

Growth performance was similar for these raceways and reached 27.3 kg/m3, 44.40 kg/m3 and 56.93 kg/m3, respectively, for these three groups of raceways. This observation is also confirmed by the resulting average specific growth rate for each group of raceways: 2.83 percent gain/day, 2.86 percent gain/day and 2.88 percent gain/day for raceways 3-4, 6-7 and 1-2-5, respectively.

Daily feed applications in the raceways were made using a continuous satiation feeding protocol over 8 hours per day on a daily basis. Fish were offered diets with 40 percent crude protein (10 percent of volume), 32 percent crude protein (75 percent of volume) and 30 percent crude protein (15 percent of volume) over the course of the trial. Two employees were responsible for feeding and cleaning the raceway gates to maintain the correct and continuous water flow in the seven raceway units.

Water chemistry was measured and recorded during this IPRS production demonstration. Total ammonia nitrogen was reported to be no higher than 3 mg/L from the beginning of the demonstration; nitrite testing showed non-detectable levels; alkalinity was 175 mg/L and water hardness was 530 mg/L.

There was an incident of aquatic plant die-off that was associated with a hurricane event, which resulted in a massive amount of decaying organic matter on the pond bottom, and this led to a period of reduced dissolved oxygen levels for the pond. However, reduced dissolved oxygen levels brought about by the rotting plants in the pond were controlled by the water exchange devices and the air diffusers used in the raceways, and by the continual water movement generated by the paddlewheels operated in the pond. The water exchange device (Whitewater Unit) used a robust airlift system and ably supported the fish biomass inside each raceway.

During the demonstration, water temperature was typical of summer weather patterns in Campeche, Mexico. The pond temperature recorded in the trial was typical with the exception that it dropped below 23 degrees-C during the last part of the production cycle and had some negative effect on fish growth performance.

The limited availability of fingerlings for stocking influenced the trial. However, the production cycle (in days) across all seven raceways was very similar with an average of 119.4 ± 9.2 days (CV 7.7 percent). Total biomass harvested at the end of the first full cycle for seven raceways reached 47,139 kg, with an average fingerling survival of 78.2 percent and feed conversion ratio (FCR) of 1.36±0.09 (CV=6.7 percent). These results clearly demonstrate the potential of the IPRS technology in tropical climates to yield three harvest cycles per year.

Hence, if we consider yield results from raceways 1, 2, and 5 as an estimate for average production of this type of culture system, and we assume a stocking rate of 17,000 fish per raceway (113 per m3) with 86 percent survival and harvest biomass of only 57 kg/m3, then this specific culture strategy could potentially achieve 69 tons/ha/year. Current production yields of tilapia in well-managed, static pond culture ranges from 37 to 53 tons/ha/ year, whereas the IPRS approach has the demonstrated ability to increase annual yields approximately 30 to 85 percent over current production results at this farm. Our trial results have encouraged the producer to test a higher stocking density. Currently, the IPRS at this farm has been stocked with 25,000 fish per raceway (167 fish/m³) in order to further test the production capability of the IPRS.

Perspectives

In addition to the potential for increasing fish production, the IPRS – with proper management – requires no water exchange to improve water quality. Water is only added to compensate for evaporative loss or seepage.

The IPRS management approach uses continual aeration and mixing of the full pond volume to accelerate assimilation of organic wastes and nutrients produced by fish culture and feeding. Because this continual, aerated water flow is maintained, a more stable and predictable water quality and culture environment is achieved.

Further, the opportunity for optimizing feed volume applications is evident. It was also noted by the farm owner that harvest procedures and cost of labor for fish movement were simplified and significantly reduced.

With all aspects considered, the IPRS seems to offer an economical and environmentally sustainable culture system that offers an alternative for fish aquaculturists to optimize their production resources.

Authors

-

Esau Arana

Research Associate IV

Auburn University

School of Fisheries and Aquatic Science

Auburn, AL 36849 USA -

Jesse Chappell, Ph.D.

Associate Professor Extension Specialist

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University, Auburn, AL 36849 USA -

Terry Hanson, Ph.D.

Professor Extension Specialist

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University, Auburn, AL 36849 USA -

Jairo Amezquita

Project Manager of Aquaculture Utilization for the Americas Region

United States Soybean Export Council (USSEC) – Latin America

Cali, Colombia -

Francisco Romellon

Tilapia La Granja

Campeche, Mexico -

Arturo Quiñonez

Tilapia La Granja

Campeche, Mexico -

Gustavo Lopez

Tilapia La Granja

Campeche, Mexico -

Herbert Quintero, Ph.D.

Corresponding author

Extension Aquaculture Specialist

University of Arkansas at Pine Bluff (UAPB)

Lonoke Fish Disease Diagnostic Laboratory

Lonoke Agricultural Center

Lonoke, AR 72086 USA

Tagged With

Related Posts

Health & Welfare

Chemical treatment costs reduced with in-pond raceway systems

By dividing ponds into smaller, more controllable areas, IPRS can substantially reduce chemical treatment costs, improve treatment delivery and allow new treatments that are cost-prohibitive in traditional pond settings.

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Health & Welfare

Bacillus probiotics improve hatchery, nursery production in EMS-hit Mexico

In early 2014, a trial to evaluate the effects of a mixture of Bacillus strains on early mortality syndrome bacteria during the larviculture and nursery phases for shrimp was carried out at a commercial hatchery in Mexico.