Horizontal shaking offers better flexibility and variable speed

Shrimp feeds face the unique challenge of maintaining stability in water for several hours until consumed. Immediately after immersion, pellets begin to lose dry matter due to leaching of soluble compounds and fragmentation. The loss of nutrients reduces shrimp performance and increases the organic load on the culture environment.

Need for standards

Despite the known importance of water stability to the shrimp farming industry, no standard testing method has been established. Each producer and manufacturer seems to have a unique method of evaluating water stability. Some simply observe the appearance of a handful of pellets after three or four hours in a glass of water. Others use more quantitative methods to measure dry-matter loss after immersion. The use of different methods produces disparate results, which often leads to confusion and contention.

A standard test would be desirable to facilitate shared research among feed equipment manufacturers, feed ingredient suppliers, and feed formulators about manufacturing methods to improve pellet stability. It would also provide a quality standard upon which shrimp farmers could base purchasing decisions. The ideal water stability test should be simple, quick, accurate, reproducible, inexpensive and easy to perform.

Experimental design

A series of trials was performed at the Aquatic Feeds and Nutrition Program of the Oceanic Institute in Hawaii, USA, to evaluate the water stability of pellets held in static, horizontally mixed, or vertically mixed containers at different levels of water temperature and salinity.

Both a commercial feed and an experimental diet were tested. Pellets of each type had dimensions of 2.4 mm by 5 mm and similar proximate composition (35 percent protein and 9 percent fat). Each test run consisted of leaching duplicate samples of feed (ca. 2 grams) at six immersion times (0, 30, 60, 120, 240, 360 minutes), two salinities (0, 34 ppt), and three water temperatures (15, 25, 35 degrees-C). A refrigerated circulating water bath was used to maintain the desired level of water temperature.

This study considered dry matter loss from pellets. Future studies will investigate loss of specific nutrients. The static water method was conducted in the same manner as the horizontal shaker method described below, except the shaker was turned off.

Horizontal shaking

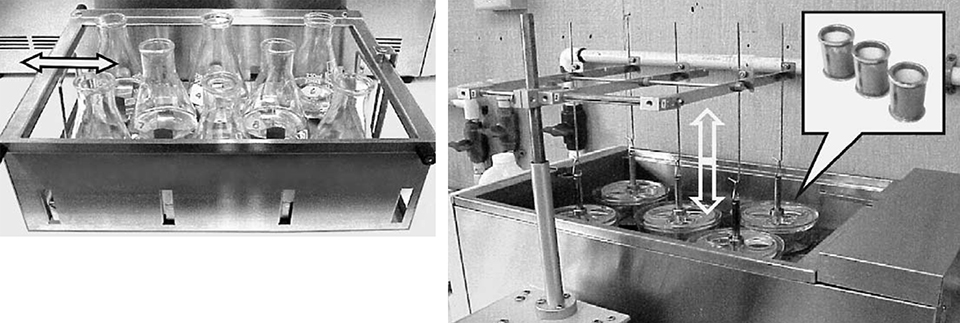

The horizontal shaking method used a shaker that provided a straight horizontal, back-and-forth motion. In this study, the shaker was set at a speed of 100 cpm, to just initiate pellet motion. Each test flask was filled with 100 ml water and 2 grams of feed for each leaching run. After shaking, all solids were recovered from the flasks.

Recovered solids and original feed samples were oven-dried at 105 degrees-C for 24 hours and then cooled in a desiccator before weighing. Pellet water stability, in terms of dry matter retention, was calculated as the ratio of dry matter recovered and dry matter of original samples, expressed as a percentage.

Vertical shaking

The vertical shaking method used a VanKel disintegration testing system, which is normally used for leaching and dissolution of tablets in the pharmaceutical industry. It provided the pellets with a straight vertical shaking motion at a fixed speed of 30 cpm. This unit has only one speed and could not be adjusted to provide different degrees of pellet agitation.

Sets of three baskets were placed in a basket rack assembly with a plastic 10 mesh (1.68 mm) screen bottom and glass housing to contain the baskets as they were lifted and lowered in a 900-ml water-filled beaker. A 381 m (U.S. #40) cylindrical stainless steel mesh basket (25 mm diameter and 40 mm height) with removable mesh cover was used to hold two grams of feed during leaching and during oven drying. This perforated basket could also be used to hold and leach pellets as small as 0.5 mm in diameter, making filtration unnecessary. The leached feed and original feed samples were dried and analyzed following the same procedure used for the horizontal shaking method.

Dry matter retention

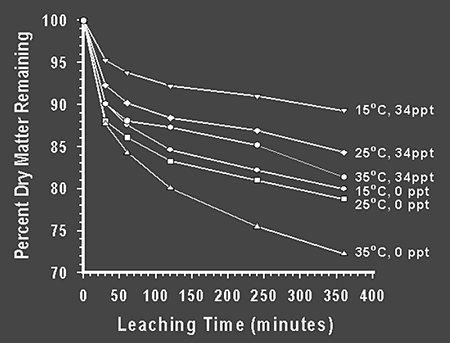

The rate of dry matter loss was rapid at early stages ofleaching and gradually slowed with extended exposure time (Fig. 1). As expected, diffusion was a driving force in this study, as evidenced by greater loss rates at low salinity and high temperature.

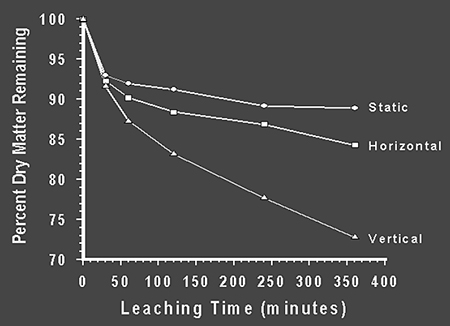

The static water method produced the lowest dry matter loss for both feeds, followed by horizontal shaking and vertical shaking methods (Fig. 2).

The percent dry matter retention after six hours of leaching under normal shrimp culture conditions (34 ppt salinity and 25 degrees-C water temperature) was 88.9 percent for the static method and 72.8 percent for the vertical shaking method. The differences in dry matter retention among the three methods tended to widen with increasing levels of leaching time.

Conclusion

A standard method for pellet stability determination should consider water temperature and salinity, in addition to the actual pellet agitation to obtain accurate and consistent measurement of pellet disintegration and nutrient leaching.

Static, horizontal and vertical mixing appeared to provide reproducible determinations of the physical stability of shrimp feeds in water. However, the horizontal shaking method offered better flexibility and variable speed to provide different degrees of agitation. This could be adjusted to simulate dry matter retention and nutrient leaching in actual indoor and outdoor shrimp culture systems.

A standard test to rapidly evaluate differences in water stability among feed types should use a high shaker speed (greater than 100 cycles per minute) and water of 0 ppt and 25 to 35 degrees-C.

(Editor’s Note: This article was originally published in the February 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Albert G.J. Tacon, Ph.D.

Aquatic Feeds and Nutrition (AQUAFAN) Program

The Oceanic Institute

Makapuu Point

41-202 Kalanianaole Highway

Waimanalo, HI 96795 USA

Tagged With

Related Posts

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Preconditioning shrimp feeds, Part 2

The effects of long steam preconditioning times of up to 30 minutes on the water stability of shrimp feeds were evaluated in early research studies.

Aquafeeds

The proper management of commercial shrimp feeds, part 1

Shrimp production systems and their feed management must be considered together. It requires an understanding of biological aspects of the targeted species and age, of production system used, of chemical and biological processes that control water and bottom quality and continuous system monitoring and feedback to provide appropriate and timely inputs and adjustments.

Aquafeeds

Twin screw technology for better extruded feeds

Extrusion processing can be a better alternative to produce high quality-low- polluting shrimp feeds. Extruded pellets with high water stability can be produced by controlling the Specific Mechanical Energy (SME) and without the inclusion of artificial binders. New extruders are equipped with state-of-the art SME controls that permit the adjustment of the SME to the desired range, to produce soft very hydrostable pellets.