Novel molecular technologies for genetic improvement, offshore aquaculture, recirculating aquaculture systems and renewable energy, alternative aquafeed ingredients, oral vaccines

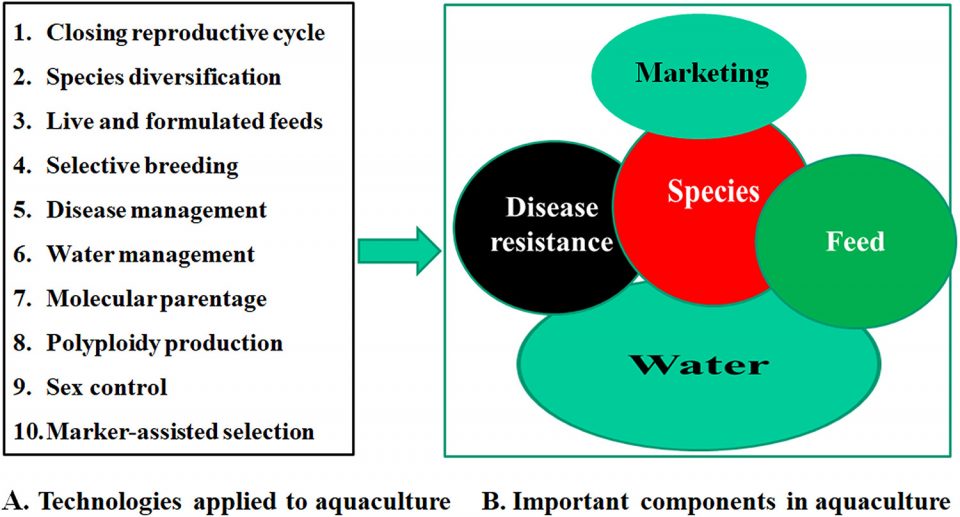

Aquaculture is the fastest growing food producing sector, per the Food and Agriculture Organization of the United Nations (FAO) and since 2013 aquaculture production has exceeded the production of wild fisheries. In the past 50 years, applications of science and the introduction of new technologies in aquaculture development have promoted its rapid development. In terms of species, aquafeeds, production systems, diseases, products, business structures and marketing, aquaculture is more diversified than most other food production sectors. Scientific and technologic advances and innovations have improved, expanded and benefited almost every aspect of aquaculture, and several pioneering technologies (Fig. 1) have contributed significantly to the production of aquaculture.

For example, improved reproductive technologies have enabled researchers to close the life cycles of many aquaculture species, which has supported significant diversification of farmed aquatic species around the world. The development and continued improvement of the use of live feeds – including various microalgae, rotifers, brine shrimp (artemia) and different copepods – in hatcheries have helped resolve a major bottleneck for the culture of several commercially important marine species. Selective breeding with the help of quantitative genetics have substantially improved traits of commercial importance in more than 60 aquaculture species.

Sex reversal technology and DNA markers associated with sex determination have enabled the production of mono-sex tilapia, yellow catfish and river shrimp. Molecular parentage has enabled intrafamily selection in mass-crosses thus reducing the danger of inbreeding. Quantitative trait locus, QTL [a region in the DNA of an organism which is associated with a particular phenotypic (observable) trait] mapping and marker-assisted selection, MAS, [an indirect genetic selection process where the desired trait is selected based on a marker (morphological, biochemical or DNA/RNA variation) linked to a trait of interest like productivity, disease resistance, tolerance, and quality) rather than on the trait itself] have enabled selection of traits determined by single genes and a few major genes.

Improved formulations for commercial aquafeeds based on the nutritional requirements of a particular species have improved feed conversion ratios (FCR) and reduced feed cost and waste. Several novel technologies for to promote health, resistance and disease management have significantly helped reduced the occurrence of diseases in aquaculture. More and novel technologies are being developed and increasingly being applied in the aquaculture industry

Emerging and disruptive technologies will increasingly offer novel ways to enhance the production, profitability and sustainability of the farmed seafood industry globally. These technologies include genomic selection (GS), genome editing (GE), information/digital technology, recirculating aquaculture systems (RAS) and renewable energy, offshore farming, oral vaccines, novel marketing strategies with blockchain and the integration of different parts of aquaculture with the internet of things (IOT), among several others.

This article – adapted and summarized from the original publication (Yue, K. and S. Yubang. 2021. An overview of disruptive technologies for aquaculture. Aquaculture and Fisheries, Volume 6, Issue 3, May 2021) – briefly outlines and discusses some of these emerging and disruptive technologies that have and will increasingly continue to revolutionize the aquaculture industry.

Novel molecular technologies for genetic improvement

Genetic improvement through breeding has been key to the boom of the world aquaculture. Conventional breeding programs have played a critical role and will continue to drive the global aquaculture industry forward. The combination of molecular technologies into existing breeding programs has significantly accelerated the genetic improvement of some aquaculture species. Marker-assisted selection (MAS) has already been applied to improve disease resistance, including resistance to infectious pancreatic necrosis, IPN [a severe viral disease] in salmonids, lymphocystis [a chronic disease of freshwater and marine fishes caused by infection with an iridovirus] in Japanese flounder, and to produce all-male tilapia lines.

Other innovative genetic biotechnologies have played important roles in improving aquaculture productivity, including sex control, polyploidization [when the cells of an organism have more than two paired sets of chromosomes], gynogenesis [a form of asexual reproduction that requires the presence of sperm without the actual contribution of its DNA, where the paternal DNA dissolves or is destroyed before it can fuse with the egg] and androgenesis [ process of development of an embryo containing only paternal chromosomes].

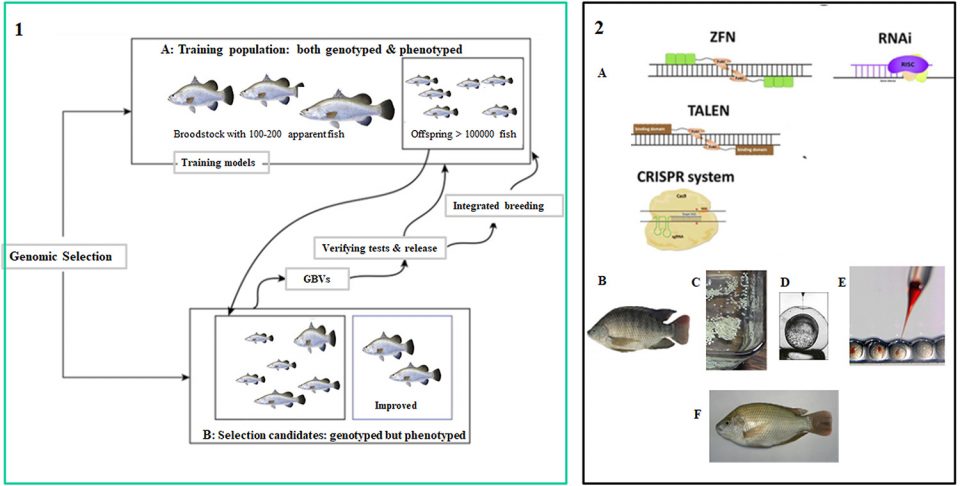

Genomic selection (GS) is a novel approach of molecular breeding. GS uses many markers as predictors of performance and consequently delivers more accurate predictions of breeding values [the economic worth of an individual’s genotype (complete set of genetic material in an organism), as judged by the average performance of its offspring (Fig. 2). With the continuous advances in sequencing and bioinformatic technologies, and the decrease in cost of single-nucleotide polymorphism, SNP [substitution of a single DNA nucleotide, the building blocks of DNA] genotyping, genomic selection using SNPs covering the whole genome and/or using selected SNPs associated with traits is increasingly being applied across many aquaculture species to optimize their selective breeding and accelerate genetic improvement.

Genome editing (GE) using CRISPR/Cas-9 [technology to edit parts of a genome by adding, removing, or altering sections of the DNA sequence] is able to speed up genetic improvement of aquaculture species when the genes to be edited are known. GE allows for rapid introduction of favorable alleles [one of two or more forms of a given gene variant] to the genome, to increase the frequency of desired alleles at the location determining important traits, to generate new alleles, and/or introducing favorable alleles from other species. Many aquaculture species are especially suitable for GE due to their generally high fecundity and external fertilization, which allows doing genome editing for many individuals simultaneously. One important issue in GE for aquaculture species is to find the right genes, which can be edited to rapidly change traits. Knowledge of gene functions in model organisms, livestock, humans and popular aquaculture species provides useful information for selecting the right genes for editing.

Advances in GS and GE will significantly reshape the aquaculture industry by helping improve the economically important traits of many aquaculture species. In the future, combining GS and GE with advanced conventional breeding strategies and various mature biotechnologies will substantially accelerate genetic improvement in aquaculture. Hopefully, consumers will understand the benefits and risks of GE and accept these emerging technologies for genetic improvement in the aquaculture industry.

Offshore aquaculture

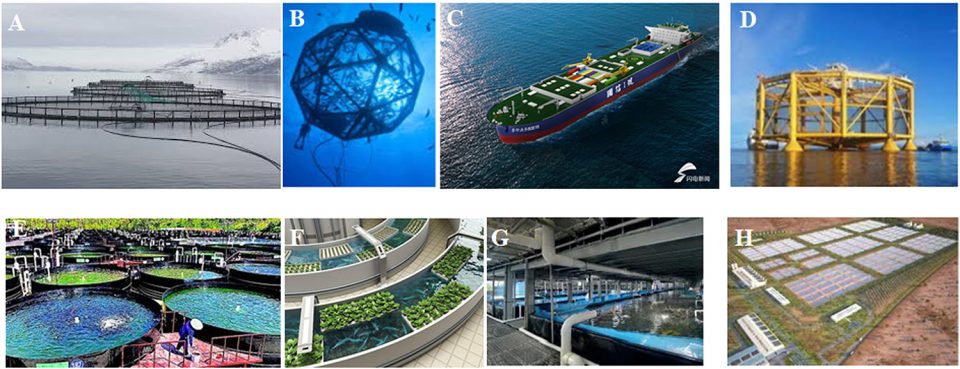

Offshore aquaculture, also called open ocean aquaculture, is a rapidly emerging and growing approach to culture marine fishes (Fig. 3). Offshore aquaculture is increasingly regarded as one of the important means to ensure a sufficient and stable supply of seafood and is an approach that minimizes the impacts of conventional marine aquaculture on the near-shore environment. In addition, offshore sites provide ample space for all required operations and benefit from excellent water quality and other advantages.

More large, leading aquaculture companies are looking at getting involved with offshore aquaculture. For example, in Norway, one company has developed the world’s currently largest offshore fish pen (110 meters wide), which can hold 1.5 million fish, and is equipped with 22,000 sensors to monitor various environmental parameters and the behavior of the fish. Another example is that of a Chinese project to build the world’s first 100,000-ton intelligent fish farming ship; the ship is 250 meters long and 45 meters wide, and is able to avoid typhoons, red tides and other severe weather and environmental issues while carrying out aquaculture operations anywhere in the world. This vessel aquafarm is expected to produce 4000 tons of high-value marine products each year. Additionally, collocation with other maritime industries – including shipping, fishing and tourism – is an interesting prospect for future, offshore fish farms.

Offshore aquaculture is still a relatively young industry and needs more technologies to be incorporated – including artificial intelligence and augmented reality – which can improve and automate various operations remotely, like feeding, sampling, monitoring and surveillance. More research is needed on the effects and consequences of offshore aquaculture on seafood security and marine environments, and the social dimensions and effects of offshore aquaculture. Offshore marine aquaculture systems require large investments, so how to reduce the cost of offshore farming is a critical issue in ensuring the sustainability and profitability of this technology.

Recirculating aquaculture systems and renewable energy

Recirculating aquaculture systems (RAS) are typically aquaculture production systems involving tanks, raceways and ponds where aquatic organisms like fish and shrimp are reared under various degrees of controlled conditions. The major advantages of RAS include the use of less water, increased biosecurity and nutrient utilization and recycling (bioflocs), and high yield per unit area or volume. Several types of commercial RAS already operate, including for various salmonids, Asian seabass (barramundi) and some flatfish species. The technology still faces a few major challenges, including insufficient knowledge about its high energy requirement, very high initial capital investment, and difficulties removing pathogens once they enter the production facilities.

Significant past and ongoing research on various RAS configurations has evaluated how to improve recirculating loop and waste treatments, and how to reduce energy costs by accessing and using renewable energy sources. Some RAS farms already are using renewable energy, including solar and wind energy. However, existing solar collector systems for aquaculture have shown issues with high capital costs and slow cost recovery, which is particularly important for many investors. An example of successful implementation is the use of low-cost solar collector systems to supply hot water for aquaculture systems; experiment results showed that the average daily collector efficiency of the system could reach 49.6 percent. In addition, wind energy may be a feasible option for offshore vessel and platform RAS farms.

Current RAS knowledge and technologies make these systems viable and profitable at present only for the culture of high value species, but with other options like aquaponics, other aquatic species may become sustainable. Many current and coming advances in renewable energy production will reduce RAS operating costs.

To reduce the cost of RAS, it is essential for aquaculture producers, scientists and engineers to work together to effectively design and continuously improve every component of RAS. As more knowledge on RAS technology is gained and with improved understanding of the interaction between its various components through research and field tests, RAS technology will continue to transform and modernize the aquaculture industry, including local production in or near urban centers, and in regions and countries with limited water resources to implement more traditional aquaculture systems.

https://www.aquaculturealliance.org/advocate/considerations-for-alternative-ingredients-in-aquafeeds/

Alternative aquafeed ingredients

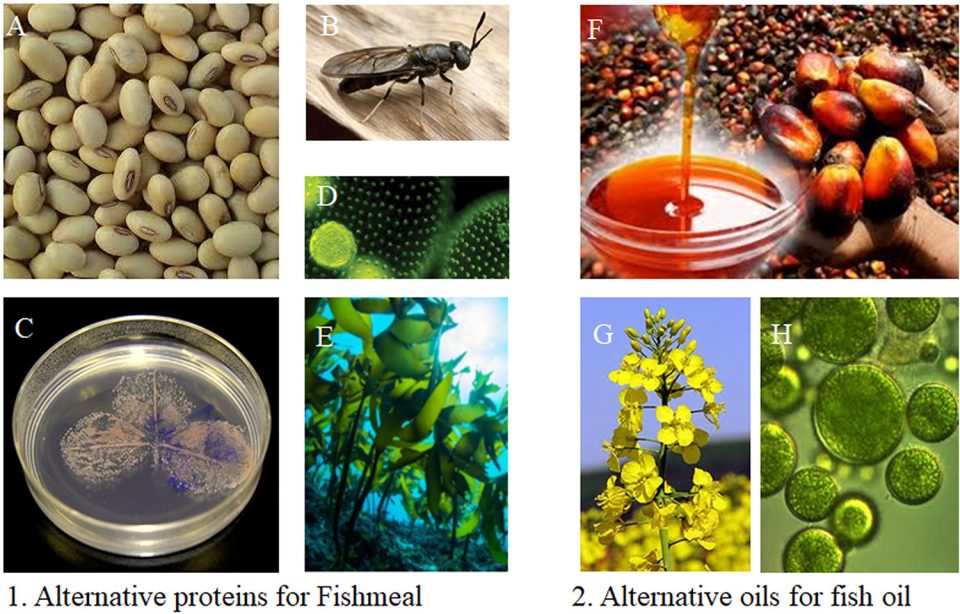

In recent years there have been numerous efforts to develop alternative aquafeed ingredients to replace and supplement marine proteins like fishmeal and fish oil, on which the aquaculture industry depended heavily for its fast growth and expansion, and marine ingredients will continue to have a role in the aquafeed industry. Various plant-based proteins like soybean protein have gained much prominence in the industry and their relevance will continue to increase.

Several novel ingredients have been developed and are already in use in the production of aquafeeds (Fig. 4). Various other alternative ingredients are based on various micro- and macroalgae species that have been incorporated into fish and crustacean feeds as replacements of fishmeal and other traditional ingredients. Many algae-based ingredients are still relatively expensive to produce and bring to market but show promising results and it is only a matter of time before they are incorporated. Many aquafeed producing companies are working on improving algae feed and increasing accessibility.

Another replacement option of fish meal is insect-based proteins. Black soldier flies and crickets are some of the promising candidates for insect-based proteins. Production protocols using food wastes for these insects have been developed and several companies have started to produce these insects and scaled up production to reduce cost.

The third type of alternative protein is single-cell proteins (SCPs), which are produced by fungi, bacteria and algae. SCPs can help supply substantial amounts of protein to the aquafeed industry and have proven adequate protein sources for several aquacultured species. In recent years, significant developments have been made to replace and complement the use of fish oil with various plant oils in formulated aquafeeds. Oils from canola, palm and rapeseed have much potential to increasingly complement and replace fish oil in aquafeeds.

https://www.aquaculturealliance.org/advocate/a-push-rapeseed-viable-aquafeed-ingredient/

Oral vaccines

Diseases are a major challenge for the aquaculture industry, and annual economic losses caused by various diseases to the global aquaculture industry are estimated at several billion U.S. dollars. Vaccination is an effective means to prevent bacterial and viral diseases, and fish have been thus immunized for over 50 years, contributing to the environmental, social and economic sustainability of the aquaculture industry. Unfortunately, vaccine development for most aquacultured species trails significantly behind the terrestrial livestock industries, with relatively few vaccines having been registered and applied in the industry. Additionally, vaccination in fish is a labor-intensive process where each individual fish is manually injected with a dose of a vaccine.

Oral vaccines are an alternative to labor-intensive traditional vaccination with hand injection, as they can minimize handling and stress to the fish and reducing mortality during and after the vaccination operation. Micro-encapsulation [process in which tiny particles or droplets are coated into small capsules, generally used to incorporate enzymes, ingredients and other materials on a micro metric scale] where antigens [a molecule or molecular structure that triggers an immune response] from pathogens are incorporated into the small capsules has potential to deliver oral vaccines to fish. Although oral vaccines are promising, their delivery is still very challenging for aquatic animals because of their aqueous environment.

Developing techniques and innovations to keep the vaccine active in water for a certain time and overcome the typically harsh gastrointestinal environment are critical to achieve effective protection for the cultured animals. Further development of effective oral vaccines must carefully design delivery systems and incorporation of desirable molecules that can enhance their effect and produce strong, appropriate immune responses. Certainly, research on alternative and emerging approaches must continue to develop effective and affordable oral vaccination for the aquaculture industry.

The second and final part of this article will discuss the disruptive potential of various information and digital technologies.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Kangning Yue, Ph.D.

Corresponding author

James Cook University, Singapore Campus

149 Sims Drive, Singapore, 387380, Singapore -

Yubang Shen, Ph.D.

Key Laboratory of Freshwater Aquatic Genetic Resources

Ministry of Agriculture

Shanghai Ocean University

Shanghai, 201306, China