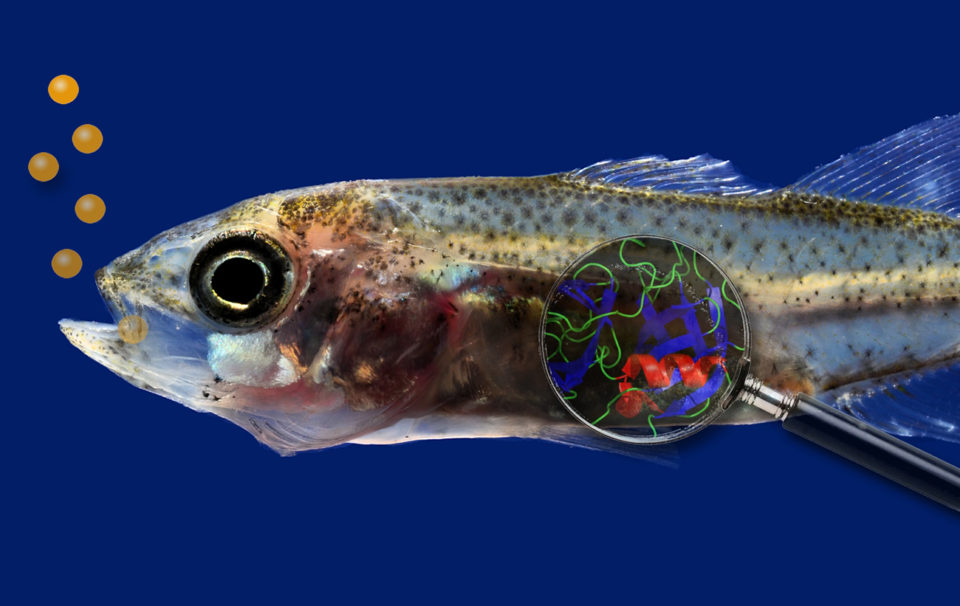

Norway-based Molofeed’s microcapsules deliver slow-release larval feed

Early-stage marine finfish and shrimp have a finicky diet, often requiring live feeds like the brine shrimp artemia. Limited supplies of live feeds has led to a race for replacements, with investors taking a keener interest in the aquafeed sector.

Aqua-Spark, the Netherlands-based investment fund for sustainable aquaculture, is now backing Molofeed, a company that has developed a proprietary micro-encapsulation technology that provides a slow release of feed to early stage fish and shrimp.

Norway-based Molofeed will receive close to €2 million from Aqua-Spark: the first infusion in the coming weeks and the second later this year.

“We’re at a stage where we’re building a more robust organization to be ready for further scaling up,” Arve Fresvik, chairman of Molofeed’s board, told the Advocate. “But we don’t have any big investment needs now, which is why we didn’t need the full amount immediately.”

Ingmar Hogoy founded the company in 2015, at which time it consisted of technology and intellectual property rights representing previous research. As he sought funding, Hogoy partnered with Fresvik, who created a consortium of investors by fall 2016. Over the past three years, Molofeed has been gradually building its production capacity in Norway and completing a series of formulations for its feed capsules for tropical shrimp, sea bream and sea bass.

While the capsules are still being tested, the feed for tropical shrimp will be ready by summer 2019. Once the production line-up is running at full capacity the company will manufacture 50 metric tons of capsules a year.

The microcapsules were created as a solution to live feed availability, and to ultimately replace it.

“Live feed is a limited resource, there are quotas for it and there are often quality issues and fluctuating prices,” Fresvik said. “Our aim is to gradually replace live feed. For farmers it means they will have more controlled feeding procedures, stable prices and less fear of illness and biohazards, as this is a formulated feed that we control all the way. We believe that in time, farmers will be able to significantly reduce their operational costs by using our feed, while achieving the same or better growth and survival rates and level of deformities.”

Each capsule is one-tenth of a millimeter in size, and its contents will vary according to the species being targeted.

“That’s the fantastic part about this technology,” he said. “Some species need feed that has a specific smell while another needs feed that doesn’t smell at all. We’re able to design the feed according to the species we’re targeting.”

Pilot customers in Europe for sea bream and sea bass, and in Brazil and Ecuador for tropical shrimp, will begin redesigning their feeding protocols to include the capsules this year. By Q3, Fresvik said commercial sales should be ramping up.

Molofeed uses salmon oil and other types of marine protein sources in its capsules, and anticipates probiotics and immune-stimulants may be part of the formula, too. Farmers will deliver the capsules via specialized feeding devices that open into hatchery tanks.

For now the company is focused on early stage feeding when the needs of the fish and shrimp are at their greatest.

“This is where we really create value for hatcheries,” Fresvik said. “But it is possible to use the capsules in later stage feeding too, with small adjustments in the manufacturing process. So there’s quite a sizable market for us.”

Prices for the capsules have not been established yet but Fresvik said that given the many benefits the capsules have compared to current feeding protocols, it will be a good deal.

Having Aqua-Spark’s support is a significant boost for Molofeed, he acknowledged.

“While we could have received that same funding elsewhere, Aqua-Spark’s backing is important because of their global network and presence. Becoming one of their portfolio companies will open doors to market segments that interest us,” he said. “In addition other companies in their portfolio, such as those farming insect protein, could be really useful to us as we move forward. That was absolutely the most important reason for teaming up with Aqua-Spark.”

Tom Prins, dealflow manager at Aqua-Spark, said that demand for formulated diets will strengthen because of limited availability and high prices of live feeds like artemia.

“Molofeed products have the potential to decrease and replace the need for live feeds in the hatchery phase of marine fish and shrimp. By doing so it allows for reducing costs and the issues related to the use of live feeds,” he said. “Furthermore, it decreases the risk on disease transmitted through live feeds, decreases labor, energy and enrichment costs related to live feeds, and it simplifies hatchery management as a whole.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Lauren Kramer

Lauren Kramer, a Vancouver-based correspondent for the Global Aquaculture Advocate, has written about the seafood industry for the past 15 years.

Tagged With

Related Posts

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Aquafeeds

A push for rapeseed as a viable aquafeed ingredient

One Germany-based company says rapeseed protein concentrate, or RPC, can help aquafeed manufacturers meet growing demand.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.