Freezing maintains initial sensory and nutritional quality of the food

Freezing has been used as a method of preservation for thousands of years, but it was not until the invention of mechanical refrigeration that it became commonplace in food processing. The reason freezing increases the shelf life of food is that as temperature decreases, chemical reactions slow down, frozen water reduces microbial activity and a portion of the microbial population is killed during the freezing process. Salting, brining, drying and canning also improve shelf life, but freezing is often preferred over other types of preservation because the initial sensory and nutritional quality of the food is maintained.

Shrimp-freezing methods

The varied freezing methods used in the shrimp industry function at different temperatures. These include direct immersion in cooling media like salt water brines (minus-13.3 to minus-15.0 degrees-C), cold air blasts using ammonia or freon (minus-28.9 to minus-40.0 degrees-C), direct contact with cold plates, freezing in carbon dioxide snow or gas (minus-67.8 degrees-C), freezing in nitrogen gas (minus-112.2 degrees-C) and immersion in liquid nitrogen (-195.5 degrees-C).

“Cryo-mechanical” methods utilize a nitrogen or carbon dioxide system to freeze the outside of the food before it enters an ammonia or freon system to complete the freezing process. This can sometimes be more economical, depending on shrimp volume and processing speed.

Heat removal

The freezing temperature of shrimp is minus-2.2 degrees-C (28 degrees-F). In order to reach the frozen state, heat needs to be removed. The calculation of how much heat – typically expressed in British thermal units (btu) – needs to be removed to lower the temperature of shrimp from its initial state to a targeted frozen temperature requires three primary steps.

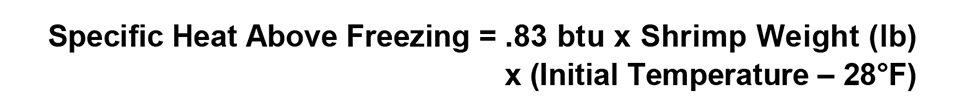

The first step is going from the initial shrimp temperature to just above the freezing temperature. This is called the specific heat above freezing. This value can be calculated with the following equation:

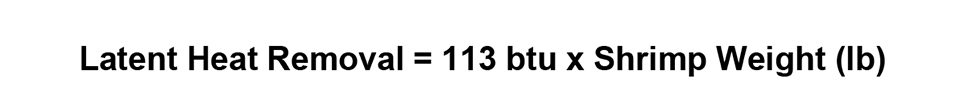

The second step is called latent heat removal, which occurs when heat removed from the water in the shrimp is converted into ice at 28 degrees-F. The following defines this value:

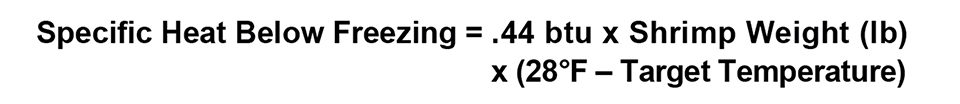

As expressed in the following equation, the third step takes the shrimp from 28 degrees-F to the target temperature to achieve the specific heat below freezing:

Applying the three equations, the total amount of heat removed to take one pound of shrimp from 70 degrees F (21.1 degrees-C) to minus-10 degrees F (minus-23.3 degrees-C) is about 165 btu. This is a theoretical calculation, as actual commercial operations require about 10 percent more btu.

Even though the freezing temperature of shrimp is minus-2.2 degrees-C, commercial processors usually freeze shrimp to minus-23.3 degrees-C and then glaze them with water to prevent dehydration during storage. Glaze water temperature is about 4.4 degrees-C, and the shrimp warm up to minus-17.8 to minus-12.2 degrees-C, which is the average temperature of most holding freezers.

Moisture loss

At about 78 percent water, shrimp are a high-moisture food that can lose moisture if frozen unpackaged. The amount of moisture lost depends on the temperature and dew point of the freezing system. High-velocity air removes moisture from the surface of the shrimp and thereby decreases the overall weight of the final product.

Weight loss continues while the shrimp are in the freezer until the surface of the shrimp forms a frozen crust. Moisture loss before crusting can be upwards of 6 percent in some mechanical freezers. Because shrimp is mostly sold by weight, limiting the weight loss is an important economic decision.

Many processors find that if they are located close to a liquid nitrogen or liquid carbon dioxide source, the product weight saved by the much faster cryogenic freezing process can more than pay for the cost of the cryogen used to freeze the shrimp. Nitrogen at minus-195 degrees-C, for example, provides freezing times of less than five minutes versus over 30 minutes in mechanical systems. In addition, the footprint of a cryogenic system is normally a fraction of that required for a mechanical system, a decided advantage in smaller plants.

Handling

Even when shrimp are frozen under the best conditions, their quality can still be degraded by poor handling, holding conditions and packaging. One of the most consistently overlooked faulty practices is to freeze shrimp and then not move them promptly into holding freezers. The authors have seen boxed shrimp sit in a 10 degrees-C packing room for an hour while full pallets are assembled.

The shrimp on the outside of the first layer on the pallet tend to defrost, and what was called individually quick-frozen (IQF) product will no longer be IQF. Once the pallet is moved to the holding freezer, the partially defrosted shrimp will refreeze, but that could take two days. These shrimp will be clumped and have large ice crystals that lead to increased weep, while the shrimp cases at the top of the pallet, which were exposed to the higher packing room temperature for only a short time, will have the expected quality.

Storage

The temperature of the holding freezer is also a consideration for proper storage of frozen shrimp. While freezing greatly retards nutrient loss and flavor and color changes, normal holding freezer temperatures don’t entirely stop them. At minus-5.4 degrees-C, nearly 25 percent of the total water in the shrimp is not frozen. This allows these mainly oxidative chemical reactions to proceed fairly well.

At minus-21.1 degrees-C, the unfrozen water decreases to approximately 10 percent, which greatly retards further degradation. Sashimi-grade tuna should be stored at minus-73.3 degrees-C to maximize quality retention during frozen storage. Therefore, particularly if frozen storage is longer than a few months, colder storage may be required to properly care for the product.

When freezing takes hours, larger ice crystals develop. When shrimp are quickly frozen via cryogenic methods, the ice crystals in the product are very small because they form within minutes. Very small ice crystals do not puncture cell walls, while large ice crystals do, leading to increased moisture loss at thawing.

However, in a phenomenon called Ostwald Ripening, smaller ice crystals are absorbed into larger crystals over time. This is a thermodynamically driven spontaneous process, so the higher the storage temperature and the more defrost cycles a product sees, the higher the rate of “ripening.” Shrimp that have been optimally frozen can be seriously degraded by months of frozen storage under fluctuating temperature.

Packaging

Packaging choices also affect frozen shrimp quality. “Freezer burn” is generally defined as cell damage related to moisture loss through desiccation. At its extreme, the process is illustrated by ice cubes in a freezer that shrink and then disappear over time. This is because water evaporates at all temperatures, known as sublimation, from a solid phase to the atmosphere. We have all seen IQF shrimp with freezer burn in a bag with ice crystals on the surface of the shrimp and the inside surface of the bag. In addition, the shrimp themselves begin to have a different color and look burned.

When high-moisture shrimp are packaged, the surrounding air is very cold and thus very dry, as cold air holds very little moisture. The vapor pressure between the moist shrimp and the dry air accentuates the sublimation of water vapor into the dry headspace until the headspace and the shrimp have equal water activity.

Bags and other containers for shrimp should be hermetically sealed. Otherwise, equilibration never occurs due to air leakage. Containers should also have a minimum of headspace, for the greater the headspace in the bag, the more sublimation occurs. Freezer burn is accentuated by the defrost cycles in holding freezers, so shrimp should ideally be held at colder temperatures with limited defrost cycles.

(Editor’s Note: This article was originally published in the September/October 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Tara Etheredge

Food Specialist

Air Liquide Industrial U.S.

801 West North Carrier Parkway

Grand Prairie, Texas 75050 USA -

Ron Idol

Business Development Manager Group Expert

Air Liquide Industrial U.S.

801 West North Carrier Parkway

Grand Prairie, Texas 75050 USA

Tagged With

Related Posts

Intelligence

Critical decisions for shrimp harvesting and packing, Part 2

The decision to harvest involves consideration of various factors, including market prices, customers’ need, biomass and condition of the animals and others. Several steps are involved, most aimed at maintaining maximum quality of the animals as they are harvested, sacrificed, treated and transported to the plant and processed and packed.

Intelligence

Critical decisions for shrimp harvesting and packing, Part 3

In this final installment of Hervé Lucien-Brun’s comprehensive three-part series, the author details the final steps in the process of taking farmed shrimp to the marketplace. Here we take a look at the proper protocols for receiving at the processing plant, weighing, grading and freezing.

Health & Welfare

Cool it: Refrigeration basics for aquaculture operations managers

The basic premise of refrigeration is to move heat from a colder heat source to a warmer heat sink. Common pitfalls for refrigeration in aquaculture are a lack of water flow, inadequate evaporator capacity and evaporator freezing.

Intelligence

EMS impacts: Disease shifts shrimp supplies, prices, future production

Early mortality syndrome (EMS) has led to reduced production in major Asian shrimp-farming areas and resulted in higher prices for shrimp. The situation provides opportunities for low-intensity producers in Latin America and other traditionally secondary shrimp producers to expand output and fill the supply void.