Results showed production over 48 tons per crop, with adequate survival, FCR, condition factor

The In-Pond Raceway System (IPRS) is a technology to increase fish production with reduced environmental impact. Under development since the early 1990s, it is currently being evaluated and implemented in various regions around the world, promoted by the U.S. Soybean Export Council (USSEC), Auburn University (Alabama, USA) and other organizations.

The IPRS concept is to concentrate fed fish in cells or “raceways” within a pond; these raceways – supplied with constant water circulation to maintain optimal water quality – improve feed management and other production parameters. The technology can potentially reduce solid waste loading in the pond by concentrating and removing it from the downstream end of raceway units. Water circulation, mixing and aeration are critical elements to this approach because it accelerates assimilation of organic loading of the pond feeding the fish.

Some of the challenges the system faces include the potential for disease outbreaks due to higher densities in some species and the need for having backup electrical energy. However, it allows for more effective prophylactic treatments for managing fish health and ultimately higher annual yields from the pond.

This article presents the results of a trial at a commercial tilapia farm in Veracruz, Mexico, using IPRS units. The objectives of the study were to validate the IPRS technology culturing Nile tilapia (Oreochromis niloticus) under intensive production conditions; to produce fish averaging 550 grams for the Mexican national market, while feeding the tilapia with a diet formulated to include U.S. soybean meal.

Study setup

This study was carried out at Complejo Acuícola Tupez, a commercial tilapia farm operating in Alvarado, Veracruz, México. Ten commercial IPRS units (raceways) were built in a 3.39-hectare pond with an average depth of 2.95 meters, and a total volume of approximately 108,265 cubic meters of water. Each raceway has a volume of 275 cubic meters, for a total production area of 2,750 cubic meters. Of these 10 raceways, four were used for this test, five raceways were also stocked but were not part of the trial reported here, and one unit was not stocked and was used for other tests.

Stocking of tilapia fingerlings in all the IPRS units was done on different days for each raceway, so there was a delay of 14 days between the stocking of raceways 1 and 4. the dates for stocking and harvesting varied slightly. As with the stocking, the harvest also took its corresponding time to allow for the growth of the tilapia to a commercial size averaging 550 grams. The time to harvest averaged 127 days, with a maximum of 134 and a minimum of 118 days.

Fish were fed commercial tilapia feeds (Vimifos) and followed established protocols for the farm. During the first month of the trial, a feed with 35 percent protein and 7 percent lipids was used before switching to a feed with 32 percent protein and 6 percent lipids, with soy inclusion levels of 43.4 and 33.4, respectively.

Water quality monitoring included dissolved oxygen and water temperature measurements taken daily every two hours from 10 p.m. to 8 a.m. Additional measurements for pH, dissolved oxygen and temperature were taken daily at 3 p.m. at the same time as water samples for analysis of total ammonia (TAN), for which the un-ionized part of ammonium was subsequently calculated considering water pH and temperature. Water alkalinity and hardness analyzes were done once a month.

Regular fish sampling were originally scheduled every 14 days, but due to water quality reasons, sometimes the sampling had to be postponed. During each sample collections, approximately 125 fish were collected and their average weight calculated to estimate the total biomass per raceway, subtracting any mortalities. The Fulton Condition Factor, K (a measure of an individual fish’s health based on its length and weight) was calculated based on measurements of 30 fish per sample.

Results and discussion

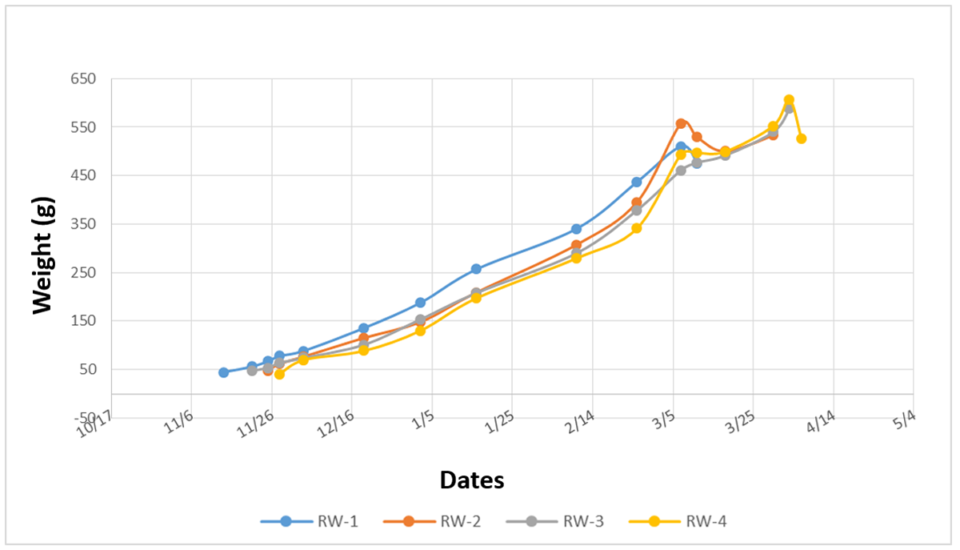

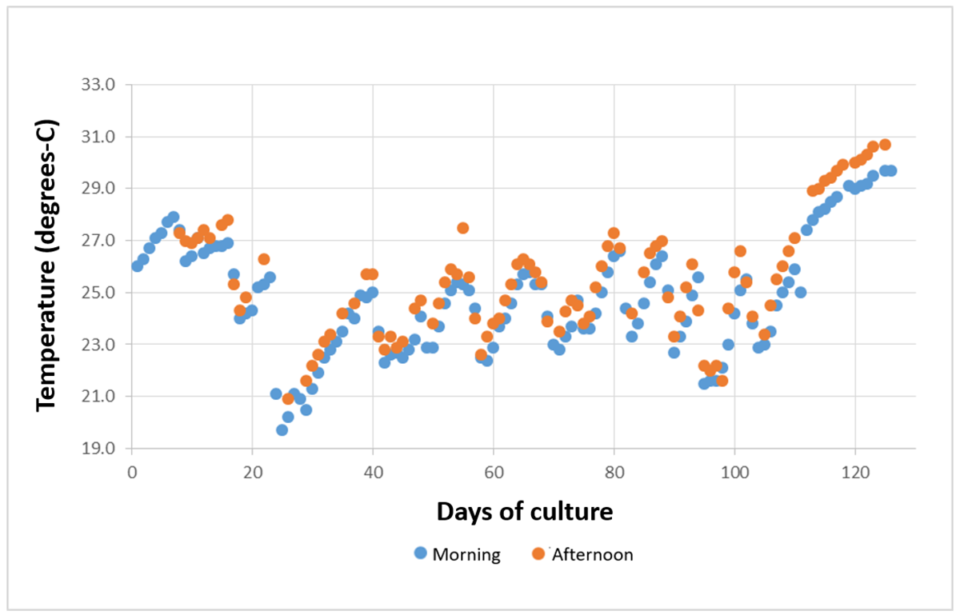

The results of the O. niloticus production trial conducted with four IPRS units are presented in Table 1. Fish growth curves (Fig. 1) show a decrease in growth at around day 95, when the biomass in the raceways begins to reach its maximum capacity. At around that time, feeding in the raceways reached a daily maximum of 800 kg feed per hectare; another factor likely influencing results was that the test was carried out from December to February, a time when the minimum water temperature in Veracruz drops to 23.0 degrees-C.

Arana, IPRS, Table 1

| Parameter | RW-1 | RW-2 | RW-3 | RW-4 | RW average | Totals |

|---|

Parameter | RW-1 | RW-2 | RW-3 | RW-4 | RW average | Totals |

|---|---|---|---|---|---|---|

| Stocking date | Nov. 14, 2019 | Nov. 25, 2019 | Nov. 21, 2019 | Nov. 28, 2019 | – | – |

| Harvest date | Mar. 11, 2020 | Mar. 30, 2020 | Apr. 3, 2020 | Apr. 6, 2020 | – | – |

| Days of culture | 118 | 126 | 134 | 130 | 127 | – |

| No. fish stocked | 38,000 | 38,000 | 38,000 | 38,000 | 38,000 | – |

| Initial fish avg. weight (grams) | 45 | 48 | 47 | 41 | 45.25 | – |

| Initial total biomass (kg) | 1,699 | 1,817 | 1,801 | 1,547 | 1,716 | – |

| Final fish avg. weight (grams) | 475 | 533 | 588 | 527 | 531 | – |

| Final total biomass (kg) | 15,541 | 18,239 | 16,469 | 15,920 | 16,542 | 66,169 |

| Biomass increase (kg) | 13,842 | 16,422 | 14,668 | 14,373 | 14,826 | 59,305 |

| Final biomass per cubic meter (kg) | 57 | 66 | 60 | 58 | 60.15 | – |

| Daily weight gain per fish (grams) | 3.6 | 3.9 | 4.0 | 3.7 | 3.8 | – |

| Final survival (%) | 86 | 90 | 74 | 79 | 82 | – |

| FCR | 1.31 | 1.15 | 1.39 | 1.28 | 1.28 | – |

| Fulton Condition Factor | 2.28 | 2.33 | 2.28 | 2.35 | 2.31 | – |

| Production (kg/ha/year) | – | – | – | – | – | 140,048 |

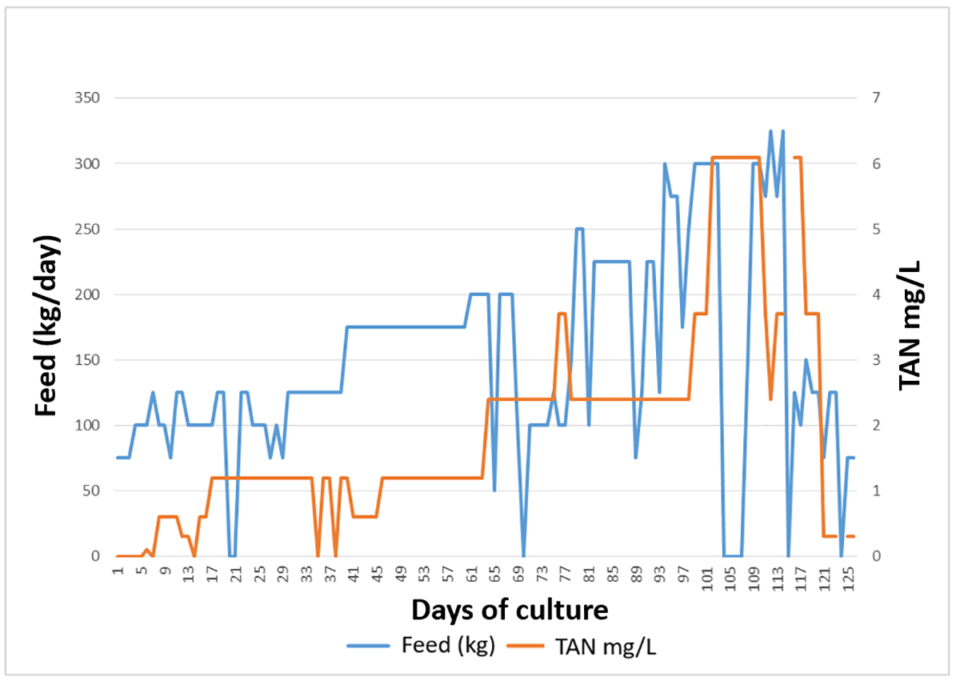

Three months after the start of the trial, an increase in ammonium levels was observed and we decided to decrease the amount of feed, and as a result there was a decrease in growth. However, despite the decline in feed applied and resulting tilapia growth at that time, overall production was not drastically affected.

Regular monitoring of water quality was very valuable, especially for ammonium levels, which increased slowly. As the growth rate of the fish increases, the feed ration also increases, reaching a maximum of 300 kg per day per raceway in the trial. Considering these conditions, we decided to harvest raceway No. 1 early, when the fish had an average weight of 475 grams. At the same time, feeding was being reduced or stopped in the other raceways, which is reflected in the growth curves (Fig. 1).

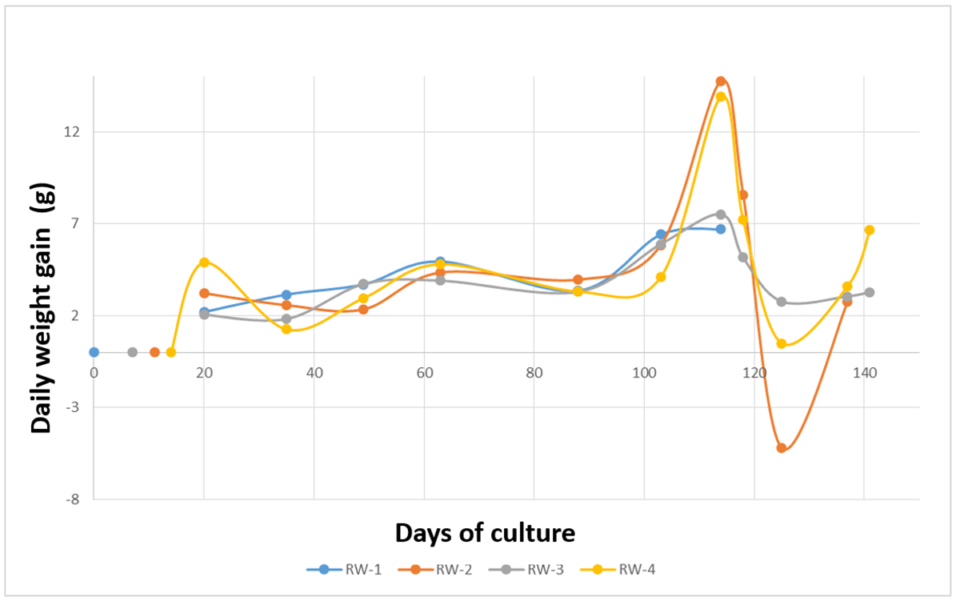

The reduction in the amount of feed provided, or not fed at all, was shown more prominently in the daily weight gain of the fish (Fig. 2). After raceway No. 1 was harvested at 118 days, it was expected that there would be a decrease in the concentration of total ammonia in the pond water. In the other raceways, feeding was continued at normal rate, and a substantially strong weight gain was observed in the fish in raceways 2 and 4. However, total ammonia levels continued to rise and feeding was completely suspended after day 120, but it resumed days later. From that moment on, in these two raceways, it remains in doubt whether the samplings were carried out according to the protocols, or if the sampling was biased towards fish of a certain size. On both dates, the fish show gains of greater than 12 grams per day and, on the next sampling, substantial weight losses. However, in raceway No. 3, the growth was more consistent.

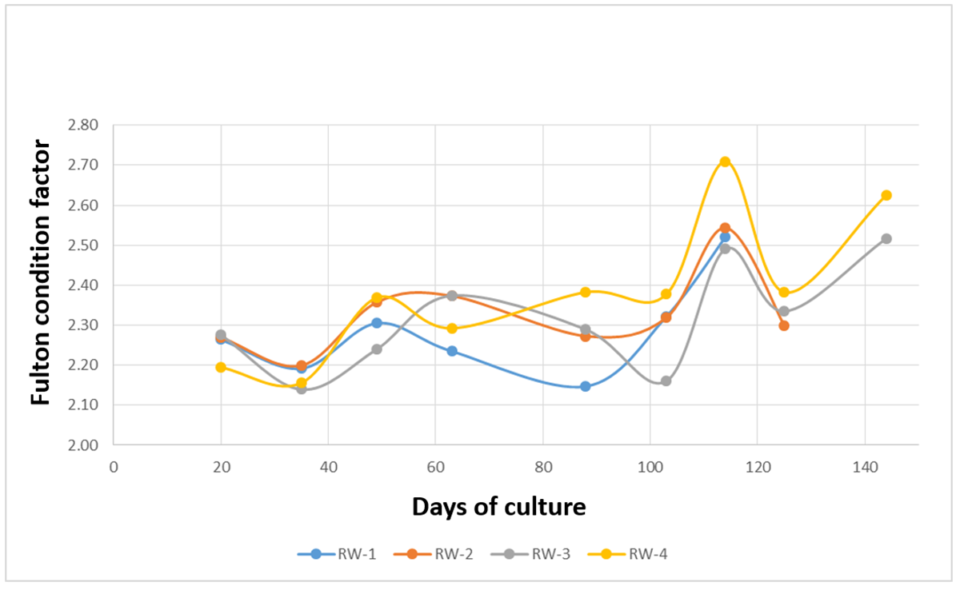

Available information on the Fulton Condition Factor (FCF) for O. niloticus in aquaculture conditions is very limited, compared to most sport fishing species; for example, for largemouth bass, Micropterus salmoides, significant such information exists. The use of the FCF in aquaculture has not been of great importance to many producers; however, when the fish farmer better understands the FCF concept and principles, and its interactions with water quality and feeding regimes of fish in captivity, the producer realizes that the FCF has a high degree of significance. Learning to not only collect pertinent field data but also to properly analyze and understand the results becomes a very effective tool for making proper technical decisions at fish farms.

In this experiment, the general average of the observed FCF was 2.31, with a range of 2.28 to 2.35 (Fig. 3). Like the daily weight gain and overall production, the FCF also showed a significant decrease after an almost continuous increase in all raceways. In raceways 1 and 3, the final average FCF was 2.28, while in raceways 2 and 4 a FCF recovery was observed after feeding was reduced. The observed effect on fish growth, daily weight gain and condition factor is strictly due to the decrease in the amount of feed provided, despite the increase in ammonium levels, which apparently had no observable effects.

In other commercial trials carried out in Honduras, Arana et al. (2019) reported an FCF of 2.22 for red tilapia (Oreochromis) sp. – this species is known to have slower growth than O. niloticus. From similar experiments, other authors reported lower FCF for the latter species. In Kenya, Ngodhe and Owuor (2019) estimated an FCF of 1.44 for free-living O. niloticus and FCF of 1.38 when these fish were grown in cages. In Pakistan, Malik et al. (2016) reported an FCF of 1.20 for females and 1.36 males for red tilapia. In Kenya, Kembenya et al. (2014), working with O. niloticus, obtained and FCF of 1.02 for males and 1.12 for females.

Other related trials include Anani and Nunoo (2016), who tested different types of diets with O. niloticus in Ghana and reported an FCFs of 1.39 to 2.01. In Kenya, Githukia et al. (2015) reported FCF values of 1.97 for males and 1.73 for both sexes combined. And in Malaysia, Ighwela et al. (2011) tested diets with different concentrations of maltose and reported FCFs for O. niloticus of 1.64 to 1.79 after eight weeks of rearing. The FCF of 2.31 reported in our study is significantly higher than those mentioned above for various trials elsewhere.

The average tilapia production of the four raceways used in this trial was 16,542 kg, with an average of 127 days of culture and a final average biomass of 60.15 kg per cubic meter (Table 1). Under the conditions of the trial – with a survival rate of 82 percent – the annual production can be extrapolated to 140,048 kg per ha. Thus, this 3.39-ha pond could have an annual production of more than 474 tons.

Regarding water quality, the pond where the IPRS raceways used in this trial are located is supplied with water from a well. This water has low concentrations of nitrites and nitrates, and excellent alkalinity conditions. Alkalinity and hardness concentrations during the trial were above 160 mg per liter and helped maintain stable pH values around 7.5 throughout the trial period.

From the beginning of the experiment until the first days of December 2019, the water temperature remained within the optimal range for tilapia growth. In January and February, the temperature dropped to 20 degrees-C on some days, but in general the lowest recorded temperatures remained around 23 degrees-C (Fig. 4). On cold days, the temperature difference between morning and afternoon did not fluctuate more than around 0.5 degrees-C.

Tilapia growth during this study was adequate, averaging 3.8 grams per day despite water temperature in the raceways dropping slightly for a few days. Similar studies have reported average weight gains of 4.0 to 4.5 grams per day.

At the beginning of the study, feeding of the fish in each raceway started at 75 kg per day and was progressively increased until it reached 300 kg per day (Fig. 5). Considering the nine raceways receiving feed (four raceways of the trial, five raceways also in production but not included in trial), at the end of the study a total of 2,700 kg of feed per day was being applied to the 3.39-ha pond where the raceways are located, or 797 kg feed per ha per day.

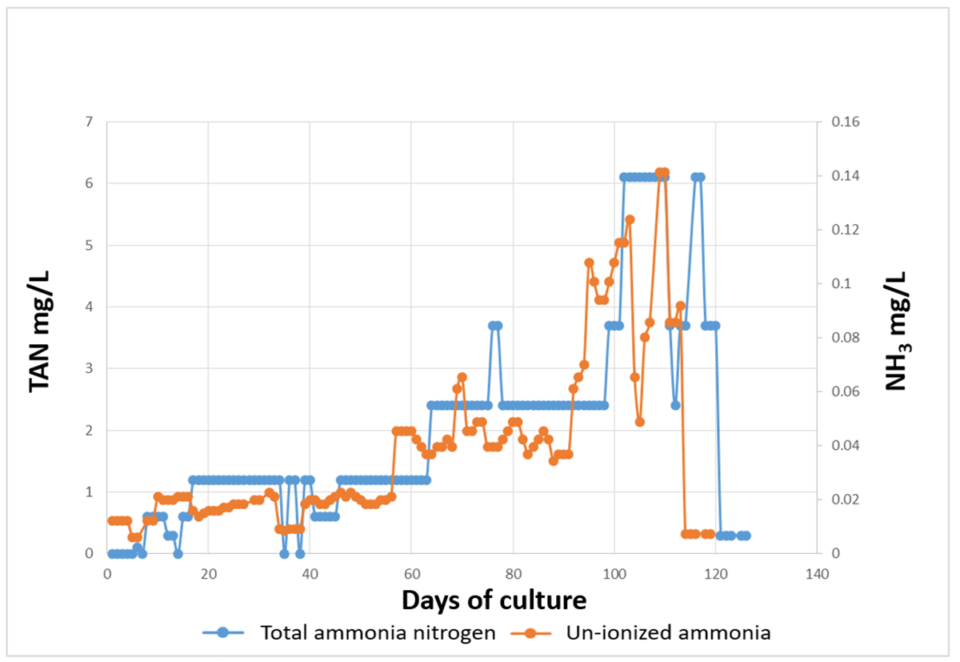

After reaching these feeding levels, the total ammonium concentration in pond water increased to a maximum of 6.1 mg per liter, generating some concern for the farm owner. As a result, raceway number 1 was harvested to mitigate the ammonium excretion load, and the feed supply in the remaining raceways was decreased from 300 kg per day to 125, 200 and 250 kg per day.

It should be noted that this tilapia farm is the first in Latin America that has an automated waste and excreta extraction system in its IPRS units. The system worked perfectly during the study and the excreta were extracted from the raceways and moved to other locations. However, despite the proper functioning of the excreta extraction system, there were constant concerns about the possibility that ammonia levels could increase to undesirable concentrations. The toxicity of ammonia increases as a function of increasing water temperature and pH. In this study, daily ammonia analyzes and calculations of the concentration of the un-ionized part of ammonium showed that the toxic component of ammonia only reached a maximum of 0.14 mg per liter (Fig. 6), lower than the lethal dose reported in the literature.

Perspectives

This is the first tilapia production trial using IPRS technology in Veracruz, Mexico (although not the first one in Mexico or Latin America), and based on the results it can be considered a highly successful experience. Despite the fact that the study was carried out during the coldest time of the year, and with stocking densities higher than those normally used, it was possible to produce 66,169 kg of tilapia in the four raceways of the trial. Extrapolating this production to the 10 raceways in the 3.39-ha pond, it could yield over 165 tons per crop, or about 48,797 kg per ha per crop.

Considering that the average number of days of culture in our trial was 127 days, it could be possible to produce 2.87 harvests per year, or results in approximately 140 tons per ha per year. This, despite the average weight gain of 3.8 grams per day observed in our trial was relatively lower than those reported in other trials. Our FCF of 2.3 was also slightly lower compared to other studies.

Another factor to consider is the influence of temperature on nitrifying bacteria – especially Nitrosomonas sp. and Nitrobacter sp. – which decrease their biological activity as the water temperature drops and causing an accumulation of ammonia, regardless of whether the excreta extraction system in the IPRS units is working adequately. However, in our trial conditions, we believed that having high alkalinity and hardness concentrations helped keep the pH relatively constant at around 7.5, and thus the un-ionized ammonium component remained at non-toxic levels for the fish.

Finally, the extraction of excreta in fish culture can play a critical role in the environmental responsibility and sustainability of the IPRS technology. However, to date, this component of the technology remains to be properly and consistently evaluated.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Esau Arana

Corresponding author

AU School of Fisheries, Aquaculture and Aquatic Sciences,

Auburn University, AL USA -

Ramón Canseco

Complejo Acuícola Tupez

Alvarado, Veracruz, México -

Gonzalo Martínez

Complejo Acuícola Tupez

Alvarado, Veracruz, México -

Jairo Amézquita

Regional Aquaculture Project Manager

U.S. Soybean Export Council (USSEC), Colombia

Tagged With

Related Posts

Intelligence

First trial growing vaccinated Nile tilapia in IPRS in Colombia

A study was conducted to evaluate the production of tilapia juveniles vaccinated against Streptococcus agalactiae type B in IPRS raceways.

Health & Welfare

Commercial demonstration of in-pond raceways

Results of a demonstration project of the In-Pond Raceway System (IPRS) technology in seven tilapia raceways at a commercial farm in Mexico showed the potential for increasing fish production with this environmentally sustainable culture system.

Innovation & Investment

GOAL 2016 preview: IPA technology catching on in China

Intensive pond aquaculture (IPA) technology, a floating, in-pond raceway system developed in the United States, is being adopted fast in China, just three years after its introduction, says Jim Zhang, aquaculture program manager for USSEC-China.

Health & Welfare

Chemical treatment costs reduced with in-pond raceway systems

By dividing ponds into smaller, more controllable areas, IPRS can substantially reduce chemical treatment costs, improve treatment delivery and allow new treatments that are cost-prohibitive in traditional pond settings.